What is the Bandsaw Blade Break-In Process?

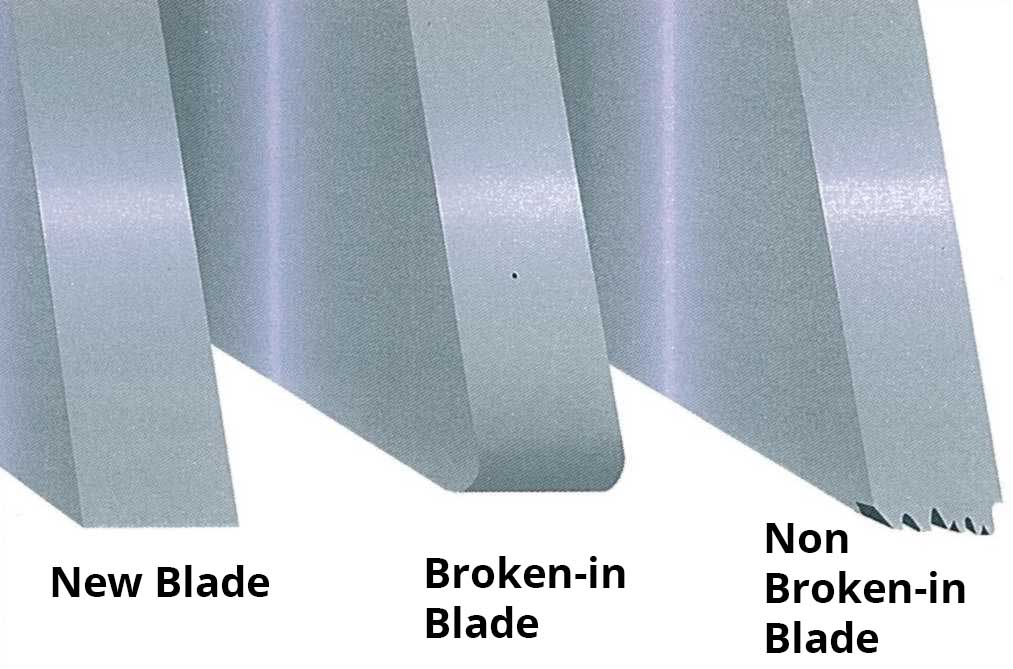

The new bandsaw blade have razor sharp cuting teeth. in order to resist microcracks and cutting pression during sawing processes, it is necessary to break-in the teeth to obtain an extremely small edge radius.

What are the Advantages of the Break-In Process?

To get the best blade life and the highest performance, we recommend that the blade be "broken in".

How to Break-In the Blade ?

1. Determine the proper cutting speed (m/min) and feed (mm/min) based on the material and dimension of the work piece to be cut.

2.It is important to only operate the new saw blade at about 50% of the determined feed during the break-in cuts. This is done to avoid damaging the extremely sharp blade teeth by micro-chipping due to excessive chip thickness. Sometimess new saw blades are prone to vibrations or oscillating noises. If this happens you may reduce the cutting speed. With small work piece dimensions, 300-500 cm² of the work piece cutting material should be cut during break in. When large work piece dimensions are being cut we recommend a break in period of 15 min.

3.After the start-up slowly increase the feed to the previously determined value.

Note: During break-in, slight speed adjustments can be made to minimize vibration and excessive noise. Once the blade has been broken-in, the recommended descent speed should always be used.