Print this page

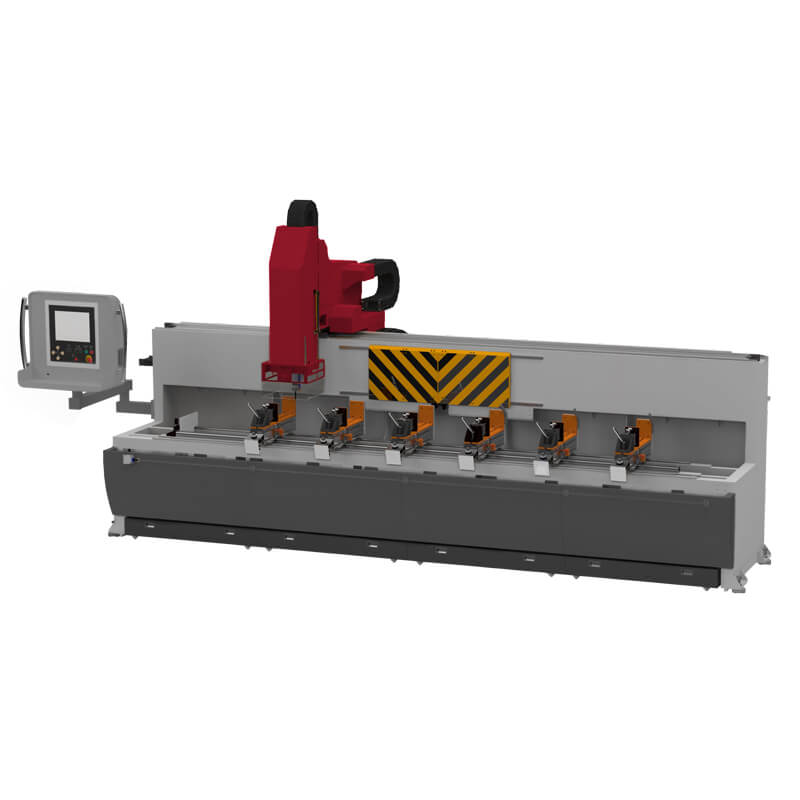

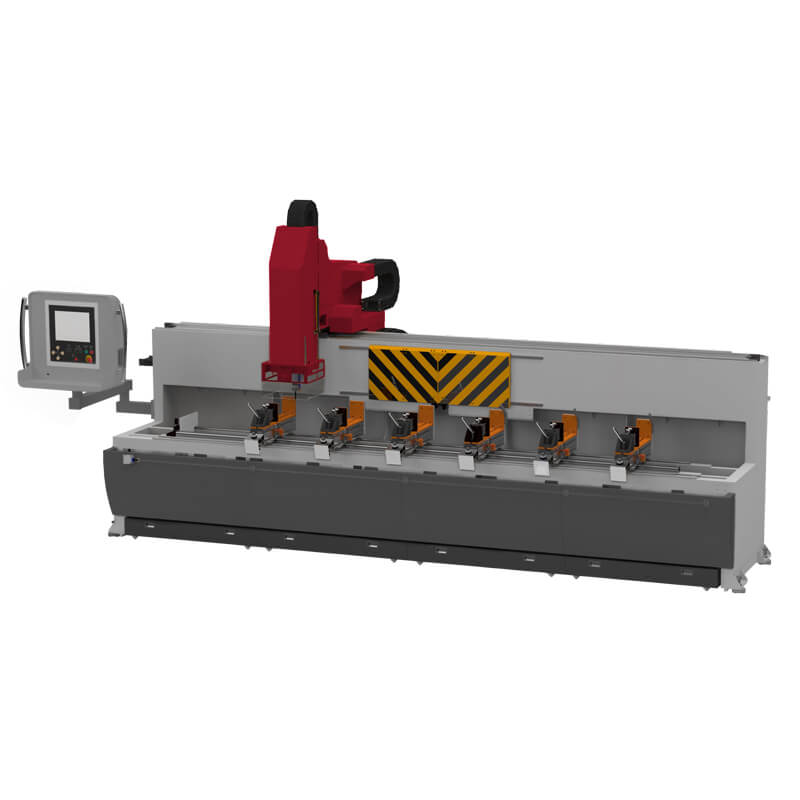

LESTHER J-CNC 300A 3 Axis CNC Machining Center for Aluminium Profiles

LESTHER J-CNC 300A Light aluminium profile 3 Axis Machining Center. Specially designed for door and windows systems and furniture and solar systems manufacturer.

Machining Center Features

• X-axis travel options: 3,500/ 4,500/ 5,500/ 6,500 mm

• Workbench type: fixture

• Spindle speed: 18,000

• Automatic tool change: 6 tools

• Moving column structure: high-efficiency, high-precision machining

• All three axes adopt advanced precision line rails

• Y&Z axis ball screw with servo motor for direct drive, no belt backlash problem, high transmission efficiency, high positioning accuracy

• New generation PC-base, Mitsubishi, Fanuc, Siemens controllers can be selected

• Optional: Rotary C-axis

Applicable Material

Aluminium

Applicable

- Aluminum Door and Windows

- Furniture

- Solar Panel Processing

Technical Specifications

| Model | LESTHER J-CNC 300A (OPTIONAL Additional C-Axis) |

|---|---|

| X Axis stroke | 4,500 mm |

| Y Axis stroke | 350 mm |

| Z Axis stroke | 250 mm |

| Table type | VISE (1set / per meter) |

| Table size | 250 x 4,500 mm |

| Table height from floor | 1,140 mm |

| Spindle speed | 18,000 rpm (Opt.24,000) |

| Spindle motor | 5.5 kw (7.5 hp) (Additional C-Axis 6.6kw / 8.8hp) |

| Spindle taper cone | NBT30 (Optional ISO 30) (Additional C-Axis HSK63F) |

| Rapid feed rate (X / Y / Z) | X:100, Y:36, Z:36 |

| Servo motors of 3 axes | X:1, Y:0.75, Z:0.75, C:0.4 |

| Cutting feed rate | F : 1 ~ 5,000 |

| Magazine capacity | 5 Tools + 1 (4 sides 90° Degree head) |

| Max. Tool Diameter | 50 mm |

| Tool holder | NBT30 (Optional ISO 30) (Additional C-Axis HSK63F) |

| Machine weight | 3,800 kgs |

| Machine dimensions | 4,332 x 2,237 x 2,208 mm |

| Packing Dimensions | 4,700 x 2,300 x 2,240 mm |

| Required pneumatic pressure | 6 kg/cm2 |

Montfort International

2500 av. Watt, Quebec City (Qc),

G1P 3T3, Canada

G1P 3T3, Canada

1-800-463-6668

info@montfort-international.com