Ficep TIPO D50-F Auto CNC High Speed Drilling & Sawing Line for Flats, Angles, Channels and Tubes

Flats, Angles, Channels and Tubes Drilling and Sawing

Automatic CNC high speed drilling & sawing line for flats, angles, channels and tubes. The addition of the innovative TIPO D50-F product line extends our technological solutions to address the fabrication of miscellaneous shapes such as angles, flats, structural tubes and channels. This fabrication line features the integration of drilling, scribing, marking and miter cutting of diverse miscellaneous shapes.

Types of Processes

- Drilling

- Scribing

- Milling

- Disc sawing

- Marking

Section Shapes

Angles

Flats

Channels

Square tubes

Rectangular tubes

Main Features

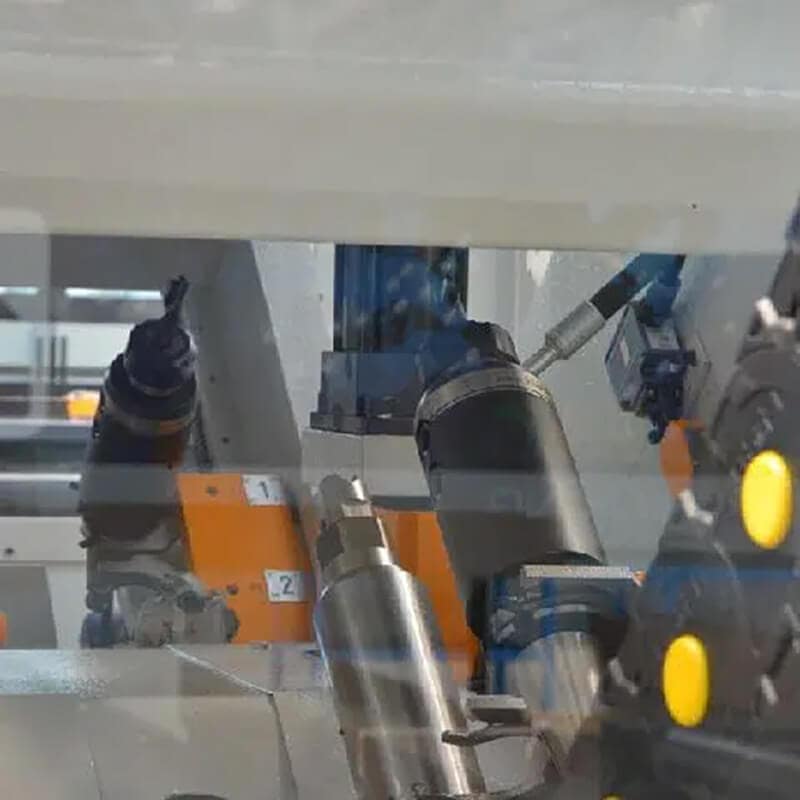

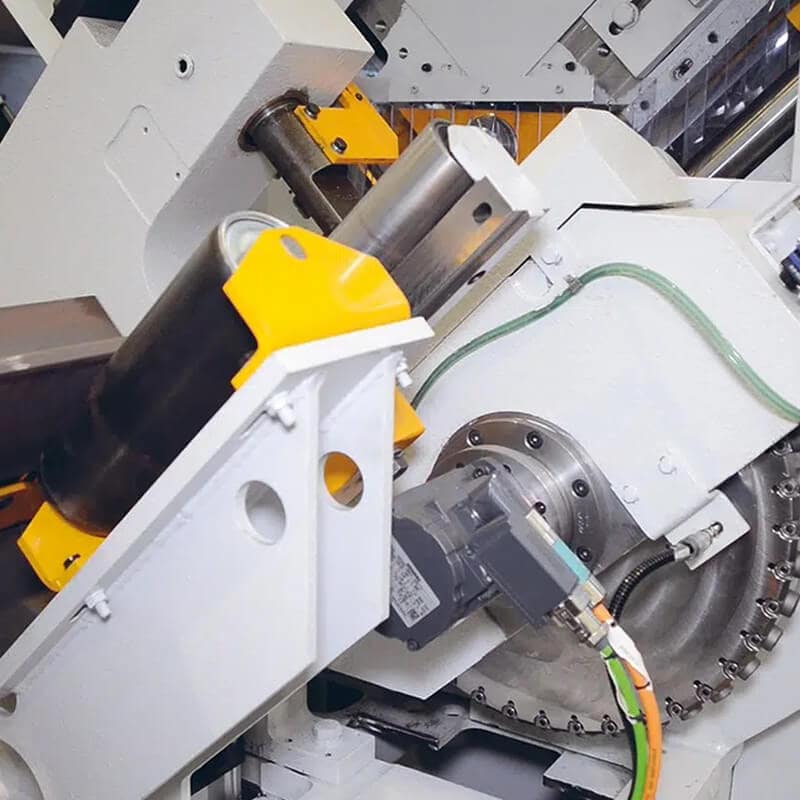

Drilling Unit

A high performance Direct Drive spindle driven by a 27 kW (37 HP) motor, equipped with a 200 mm (7-7/8”) sub-axis stroke to produce typical hole patterns without the need to unclamp, reposition and re-clamp the material for each linear move.

Automatic Tool-Changer

The drill spindle includes an 8-position automatic tool changer to address diverse applications such as slotting, milling, tapping and more.

Mitering Disc Saw

The Tipo D50-F includes a miter-cutting circular saw with carbide inserts for maximum productivity. The saw can position automatically for miter cuts of up to 60° in either direction.

Marking Unit

Prior to cutting the part to length, a programmable marking unit can be furnished to automatically generate part numbers for identification.

Second Drilling unit

An additional Direct Drive spindle, having the same characteristics of the first one, can be furnished as an option. It is also equipped with 200 mm (7-7/8”) sub-axis stroke and 8-position automatic tool changer.

Processing of Aangles

Angles with full miter cuts on both ends can be processed to generate typical framing structures. The versatility of processing flats up to 500 mm (20”) by 25 mm (1”) is exhibited with its ability to not only cut the part to length but also clip the corners as required.

Cross Transfer System

All our lines can be configured with infeed and outfeed cross transfer tables to allow automatic loading/unloading of stock lengths and finished parts.

Advantages

- Process a wide range of miscellaneous shapes such as flats, angles, channels and structural tubes

- Programmable miter cuts on both the leading and trailing ends of parts

- Optional notching capability for flats

- Integrated operations of part marking, drilling, scribing, milling and sawing to length

- Automated loading, processing and unloading without human intervention

Technical Specifications

| Model | TIPO D50-F |

|---|---|

| Flat size [min/max mm] | 50 x 6 / 500 x 25 |

| Angle size [min/max mm] | 50 x 50 x 6 / 180 x 180 x 18 |

| U channel size [min/max.mm] | UPN 80/UPN 300 |

| Square tube size [min/max.mm] | 60 x 60 / 160 x 160 |

| Rectangular tube size [min/max.mm] | 60 x 40 / 300 x 100 |

| Drilling heads [no] | 2 |

| Drilling tools per head [no] | 8 |

| Drilling diameter [max mm] | 40 (50) |

| Spindle speed [max.RPM] | 3500 |

| Spindle power [kW] | 19 (27) |

| Cutting unit | Disc saw (+/-60 °mitering) |

Montfort International

G1P 3T3, Canada