Ficep EXCALIBUR / VICTORY Automatic CNC Single Spindle Drilling Lines for Sections

Sections drilling

Automatic CNC single spindle drilling lines for sections. Ficep was the first to engineer a CNC controlled horizontal single spindle drilling line to process flats and sections for the structural steel fabrication industry. The Excalibur and Victory are the most recent developments in the family of travelling column CNC drills where the part remains stationary. Thanks to its exclusive design the Excalibur and Victory represents an economically justifiable, versatile and productive solution for small to mid-size firms.

Types of Processes

- Drilling

- Scribing

- Milling

- Countersinking

- Tapping

Section Shapes

Beams

Angles

Flats

Channels

Square tubes

Rectangular tubes

Main Features

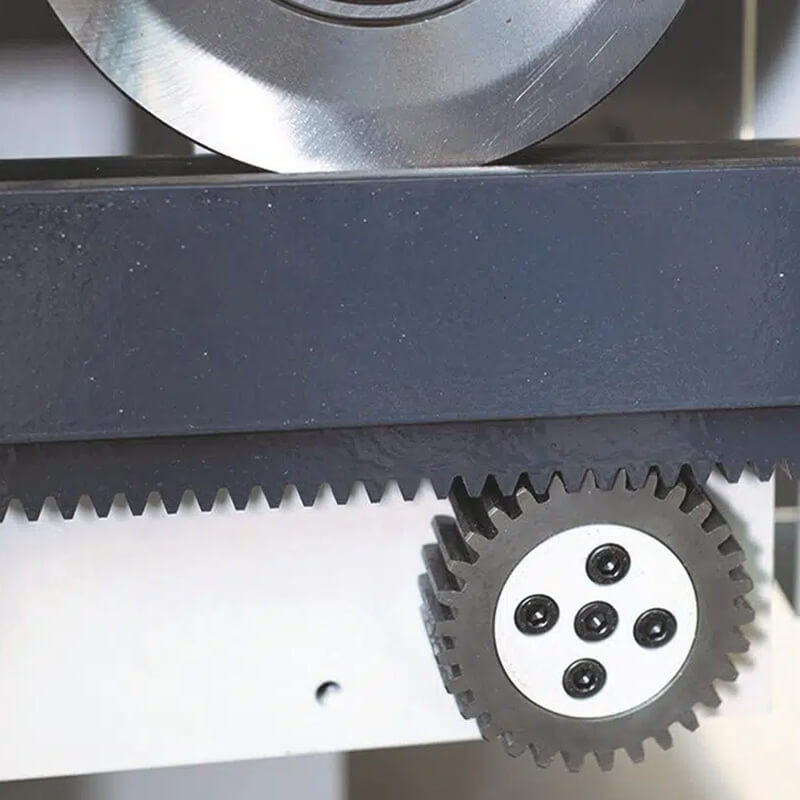

Cabin Rail

This support table is equipped with a rack and pinion system for fast, accurate and safe drill spindle positioning in the length axis.

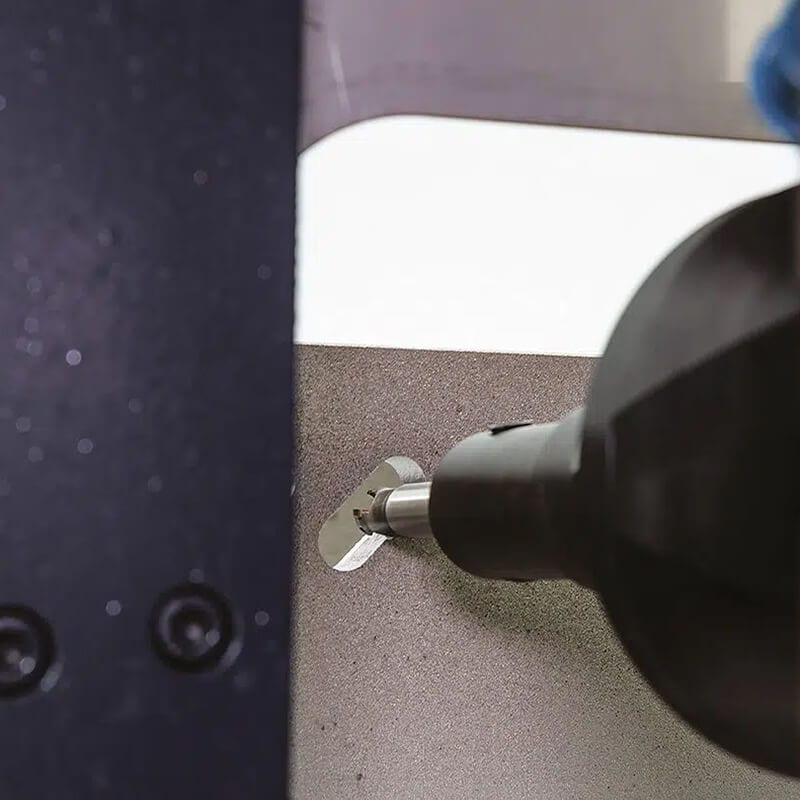

Laser Measuring

A non-contact laser measuring system is provided to sense the end of the section and the top of the web surface for precise hole positioning.

Clamping Device

The pieces are strongly clamped in the working position by an automatic double-effect hold down (top and bottom clamping).

DIRECT DRIVE Spindle

The powerful direct drive spindle ensures high drilling performances. This heavy duty, yet simple design, makes this spindle the most efficient and advanced on the market today.

Carbide Drilling

Thanks to the high RPM spindle, carbide tools can be utilized to their maximum efficiency.

Scribing

Scribing operations can be performed with a special tool.

Tool Changer

The automatic tool change system is managed by the CNC and is equipped with 9 positions.

Auxiliary Sub Axis

The auxiliary axis allows milling and scribing operations while the part and drill cabin assembly remain stationary.

Flat Processing Device

With the aid of these magnetic devices, it is possible to process plates.

Remote Control

A remote control is supplied to allow the operator to monitor the machine while carrying out other operations, such as material loading/unloading.

Safety

Safety bumpers will ensure an automatic stop in case of contact.

Advantages

- Excalibur/Victory only requires 50% of the floor space of a conventional beam drilling line.

- The unique auxiliary axis on the spindle allows operations to be performed without moving the machine cabin, assuring high precision and long life with no stress to the linear guide.

- The cabin moves over the floor level without interfering with drill chips.

- Remote diagnostics are possible through a network connection that allows our service team to perform a system analysis.

Technical Specifications

| EXCALIBUR / VICTORY | Profile size [min. mm] | Profile size [max mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max mm] | Spindle power [kW] | Spindle speed [max RPM] | Spindle sub-axis stroke [mm] |

|---|---|---|---|---|---|---|---|---|

| VICTORY 1001 EX | 50 | 1000 | 1 | 1 | 40 | 17 | 5000 | - |

| EXCALIBUR 1201 EX | 50 | 1200 | 1 | 1 (9) | 40 | 19 | 5000 | 200 |

Montfort International

G1P 3T3, Canada