Ficep ENTERPRISE Automatic Gantry CNC Drilling Line for Bridge Girders and Welded Structures

Bridge girders and welded structures drilling

The Enterprise, is an automatic CNC multiple spindle gantry drilling line that features an innovative laser probing process for the productive processing of welded bridge girders and welded structures. The gantry can accommodate either long structures or multiple short parts with loading and unloading in masked time. This expansive processing window, with laser scanning process, can eliminate the laydown procedure and manual drilling in the fabrication of bridge girders that are frequently cambered or curved. The exceptional size capability also lends itself to process box girders, trusses, and large welded structures.

Types of Processes

- Drilling

- Scribing

- Milling

- Countersinking

- Tapping

Section Shapes

Beams

Main Features

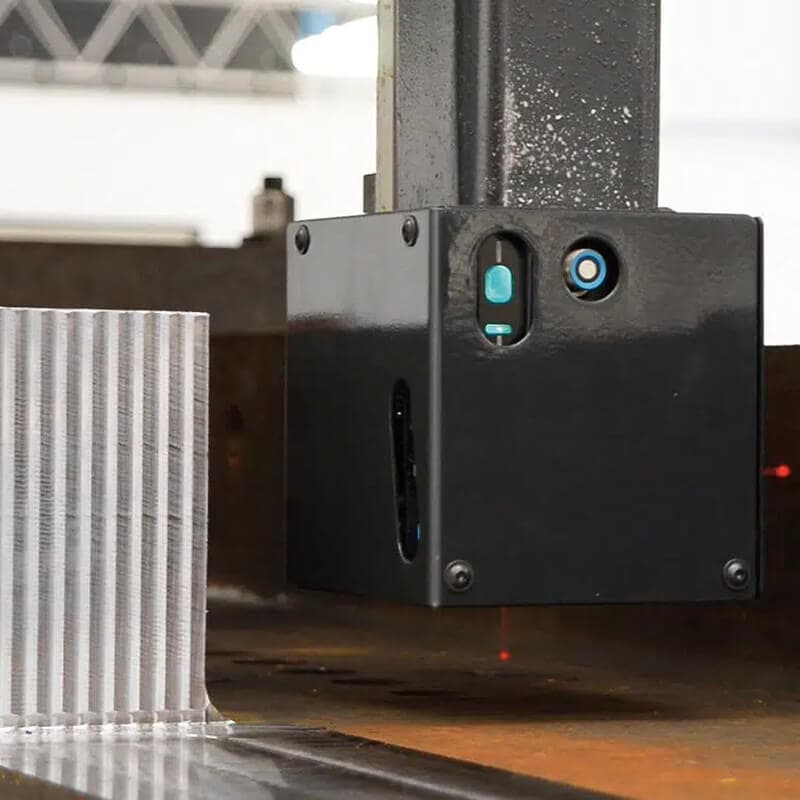

Triple Laser Measuring System

An automatic CNC controlled device, with triple laser, is used to detect the real location of the structure to position holes, for example, relative to the actual position of the part to be processed.

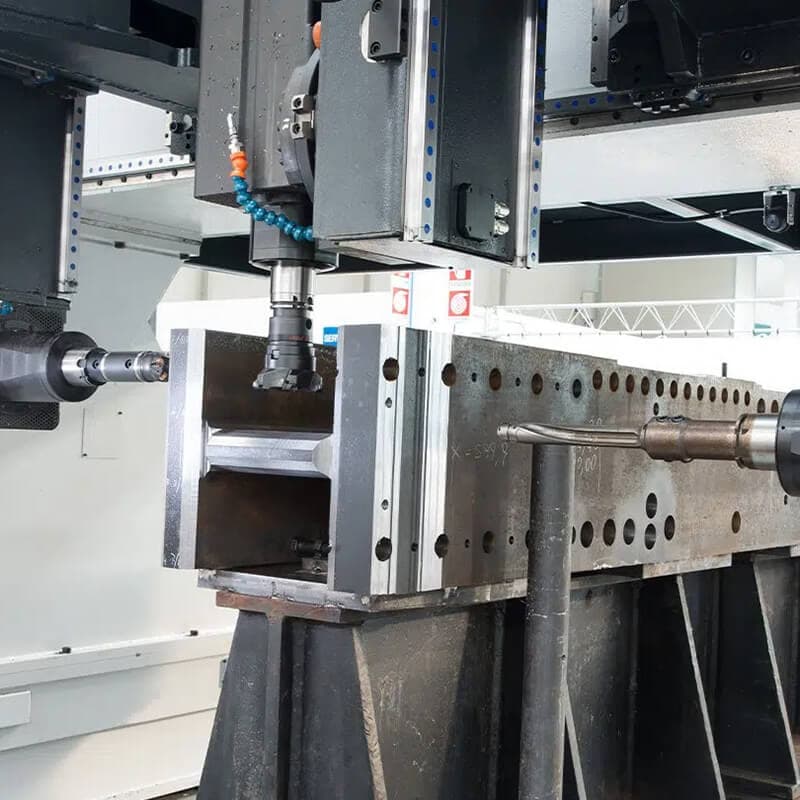

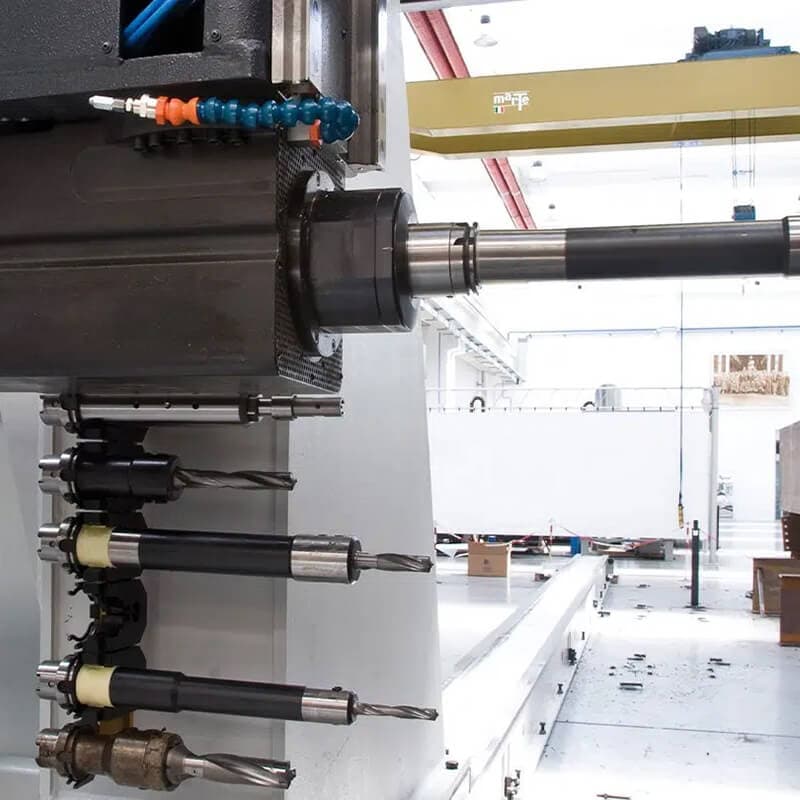

Three 31 KW (42 HP) Independent Spindles

Three direct drive independent drilling spindles delivers the motors full power to the tool.

These three high-tech spindles can operate simultaneously on both flanges and the web even when the operations in each face are offset.

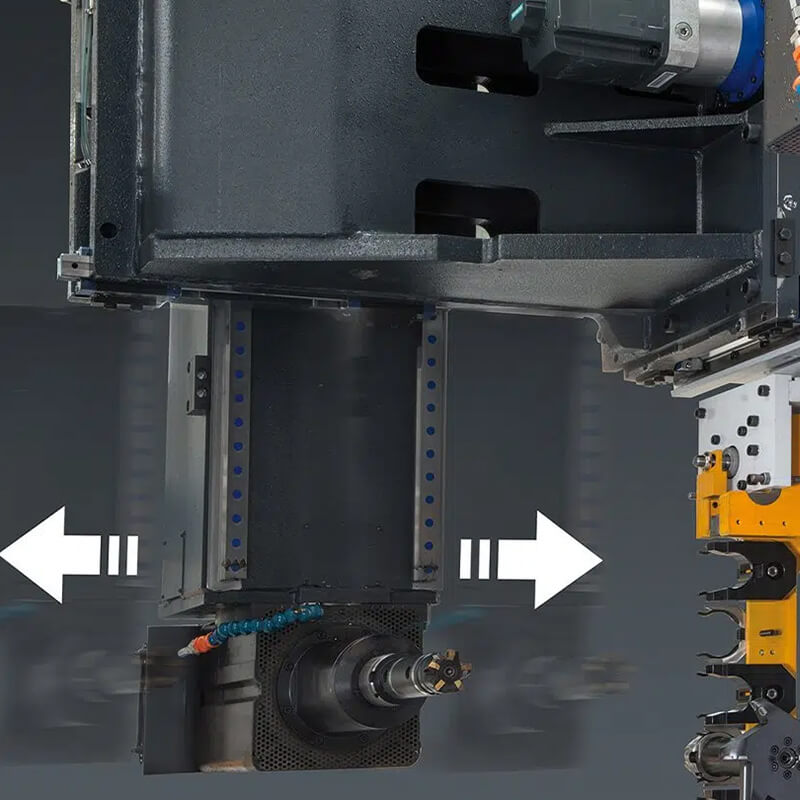

Spindle Sub-Axis

Each spindle is equipped with an additional auxiliary axis which generates an extra stroke to carry out countless operations by keeping the material clamped in position. This translates into greater flexibility and unequalled productivity.

Mitering Head for Edge Processing

Thanks to a technologically advanced concept, the vertical spindle is able to rotate to easily mill the ends of profiles.

DIRECT DRIVE Spindle

The powerful direct drive spindle ensures high drilling performances. This heavy duty, yet simple design, makes this spindle the most efficient and advanced on the market today.

Carbide Drilling

Thanks to the sophisticated spindle design, the full capabilities of carbide tooling can be realized.

Tool Changer

The automatic tool change system is managed by the CNC and is equipped with 6 positions on each spindle.

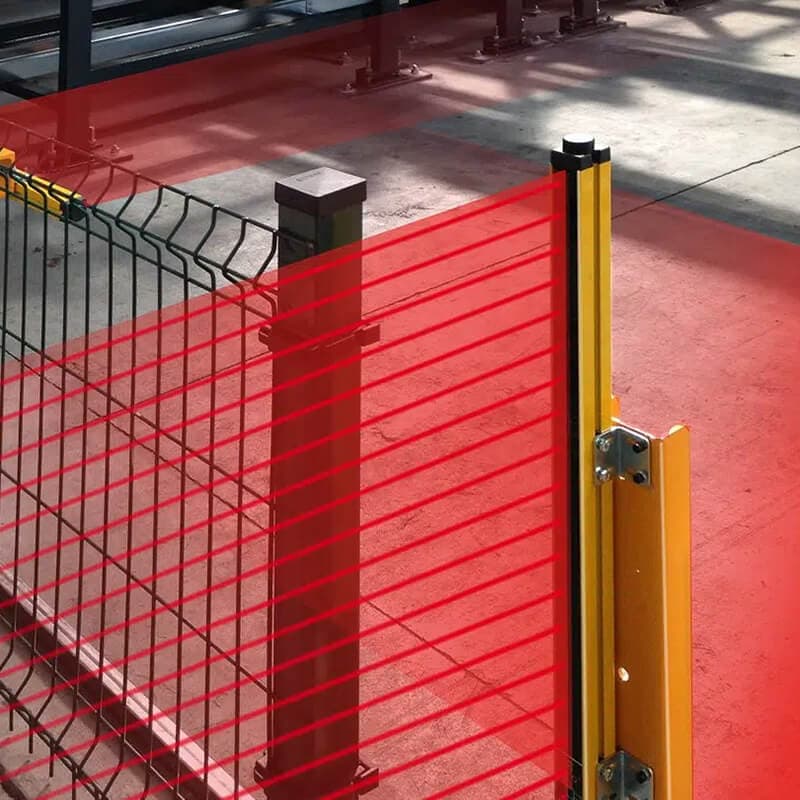

Safety

All our systems are supplied in accordance with the highest safety standards and regulations.

Advantages

- Capable of processing special profiles such as welded girders, weldments and cambered beams

- The performance of the Direct Drive spindles makes sure the highest standards of performance and quality are achieved.

- Auxiliary axes on each spindle for faster and multiple operations

- The end of sections can be milled with the rotating web spindle design.

- Remote diagnostics are possible through a network connection that allows our service team to perform a system analysis.

Technical Specifications

| ENTERPRISE | Profile size [min.mm] | Profile size [max.mm]/th> | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max.mm] | Spindle power [kW] | Spindle speed [max.RPM] | Spindle sub-axis stroke [mm] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| 1501/8 GDD | 200 x 100 | 1500 x 800 | 1 | 6 | 40 | 31 | 5000 | - | 15000 |

| 2003/8 GDD | 200 x 100 | 2000 x 800 | 3 | 6 | 40 | 31 | 5000 | 250 | 23500 |

| 2503/10 GDD | 200 x 100 | 2500 x 1000 | 3 | 6 | 40 | 31 | 5000 | 250 | 24300 |

| 3003/12 GDD | 200 x 100 | 3000 x 1200 | 3 | 6 | 40 | 31 | 5000 | 250 | 25000 |

| 3003/18 GDD | 200 x 100 | 3000 x 1800 | 3 | 6 | 40 | 31 | 5000 | 200 | 25500 |

| 4003/12 GDD | 200 x 100 | 4000 x 1200 | 3 | 6 | 40 | 31 | 5000 | 250 | 29000 |

| 4003/18 GDD | 200 x 100 | 4000 x 1800 | 3 | 6 | 40 | 31 | 5000 | 200 | 30000 |

Montfort International

G1P 3T3, Canada