Ficep NOZOMI Automatic 9 Axes CNC Thermal Coping Robot

9 axes sections thermal coping

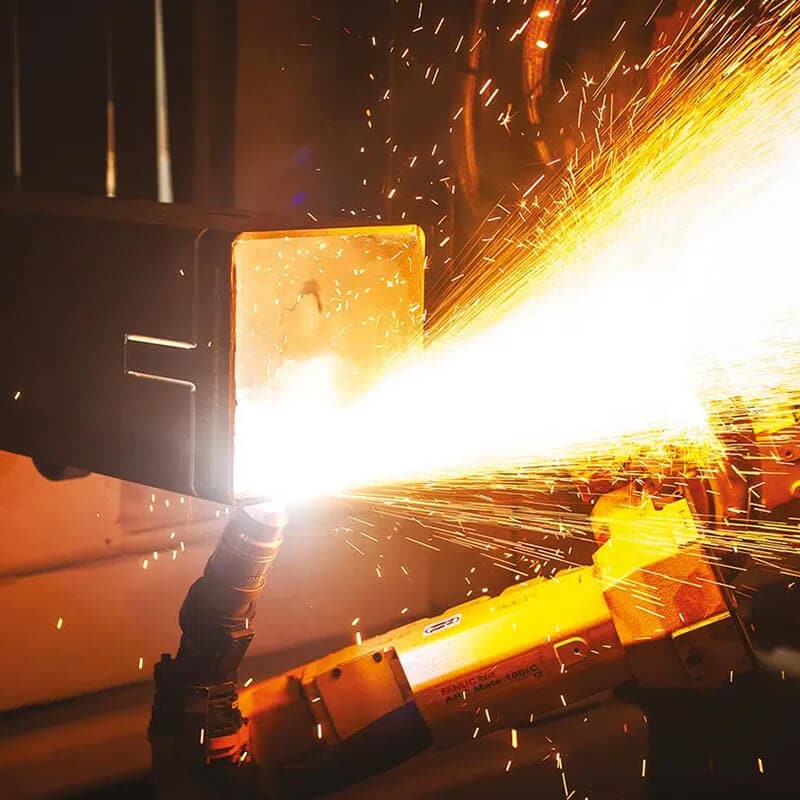

Automatic 9 axes CNC thermal coping robot. The innovative features of the NOZOMI robot makes it the optimum choice for the fabrication of structural shapes and round pipes with the plasma thermal cutting process. Today the innovative developments of Hypertherm’s “True Hole” process makes the thermal cutting of copes, mechanical openings, weld prep and in some applications bolt holes extremely efficient. An additional advantage is the use of the plasma torch for marking. This opens up capabilities such as generating part marking, layout locations with orientation marks and weld symbols all within the same thermal processing cell.

Types of Processes

- Plasma cutting

Section Shapes

Beams

Angles

Flats

Channels

Square tubes

Rectangular tubes

Main Features

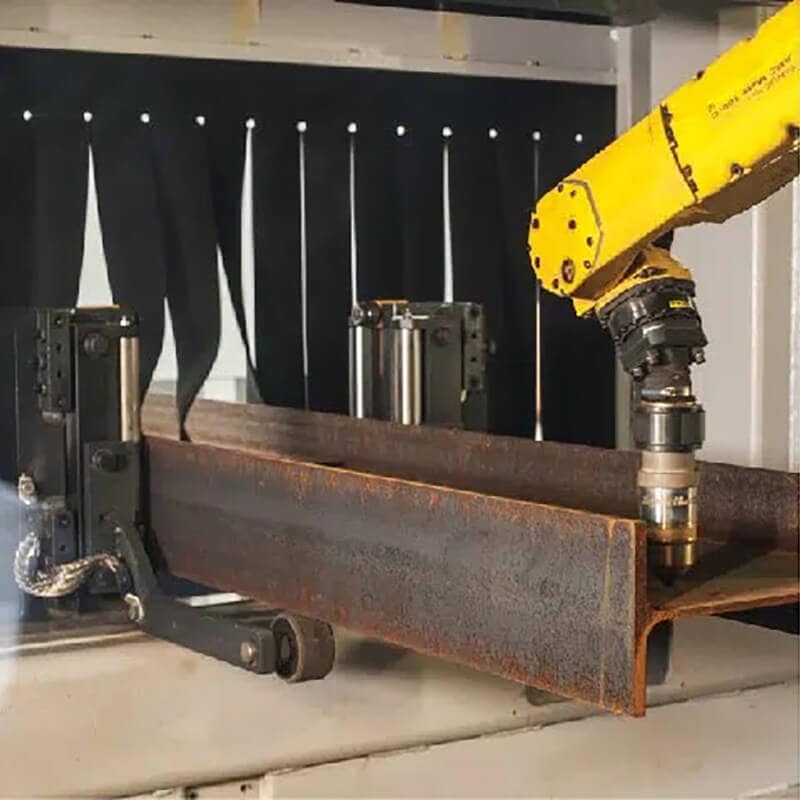

Articulating Robotic Arm

State-of-the-art robotic system equipped with 9 axes to allow 4-sides processing

Clamping

Automatic clamping devices guarantee perfect position of the profile

Laser Scanner

This new laser scanner process is used to probe multiple surfaces of the profile in seconds. This eliminates the need to mechanically probe the different section surfaces for each cut to establish an accurate torch start location.

Fume Exhaust System

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

CNC Library

This machine is equipped with a CNC library of macros to generate the most efficient cutting routines.

HYPERTHERM “TRUE HOLE”

Hypertherm’s “True Hole” process is available on this model.

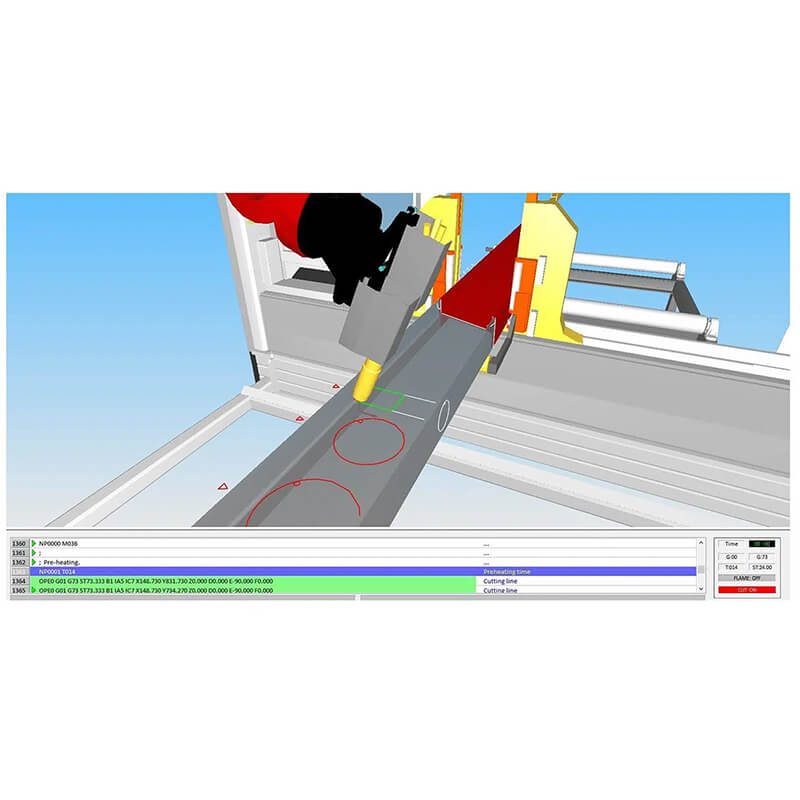

3D Simulator

The graphical 3D simulator shows the visualization of the process prior to cutting.

Single CNC Control Unit

When combined with a drilling line there is no need to add an additional CNC unit. The entire system is controlled by one single program and control.

Safety

All our systems are supplied in accordance with the highest safety standards and regulations.

Advantages

- All the manual operations of layout, marking, thermal cutting and extensive grinding are eliminated.

- All thermal cutting operations can be done in line with a drill line to save time and valuable shop space.

- The production times are drastically cut and predictable.

- Human error for manual operations are eliminated.

- The shop floor space dedicated to process these tasks manually are greatly decreased.

Technical Specifications

| NOZOMI | Section size [min. mm] | Section size [max mm] | Plasma torch [no.] |

|---|---|---|---|

| 601RAZ | 80 x 10 | 610 x 450 | 1 |

| 1201RAZ | 80 x 10 | 1220 x 610 | 1 |

Montfort International

G1P 3T3, Canada