Ficep GEMINI Gantry CNC Drilling, Milling and Thermal Cutting Systems for Large Plates

Thermal cutting, drilling and milling of plates

Automatic gantry CNC drilling, milling and thermal cutting systems for large plates. The Gemini is the complete plate processor solution for fabricators and manufacturers of all sizes. It handles from light to heavy plates for thermal cutting, marking, drilling, tapping, milling, beveling and more, with unprecedented productivity and accuracy. This achieves the lowest part cost due to its minimal floor space, low capital investment and productivity.

Types of Processes

- Drilling

- Scribing

- Milling

- Countersinking

- Tapping

- Oxy-fuel cutting

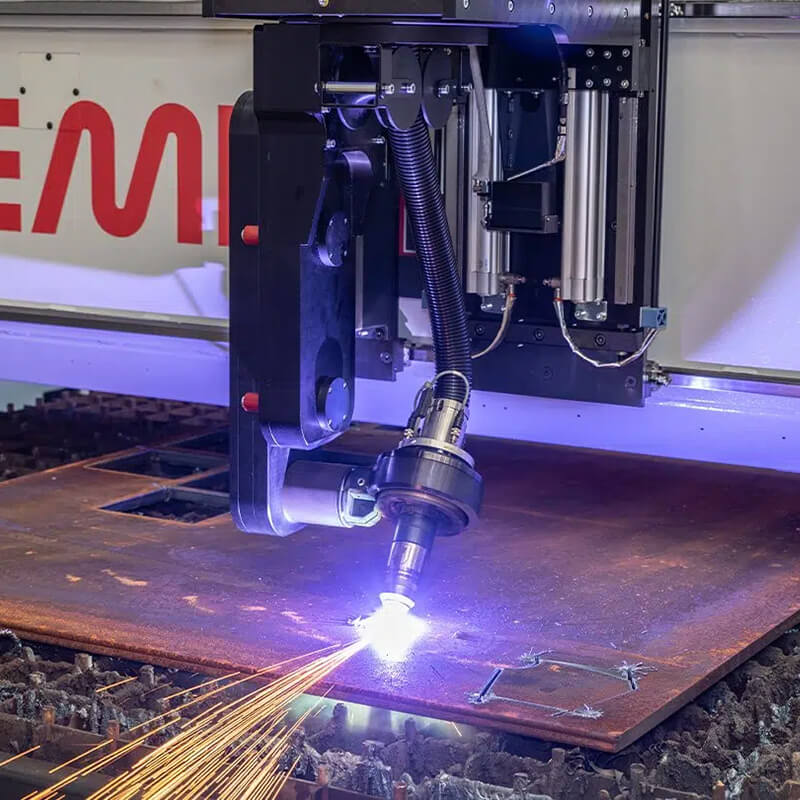

- Plasma cutting

Section Shapes

Plates

Main Features

Drilling Unit

The high speed machining spindle allows extremely productive drilling of holes from 5 to 80mm (1/4” – 3-1/8”). For larger holes up to 400mm (15-4/5”) the Gemini can mill holes with exceptional accuracy on diameter and concentricity.

Tool Changer

Automatic tool change systems, managed by the CNC, having 6, 16 or 24 positions allows to equip the line with all the necessary tools.

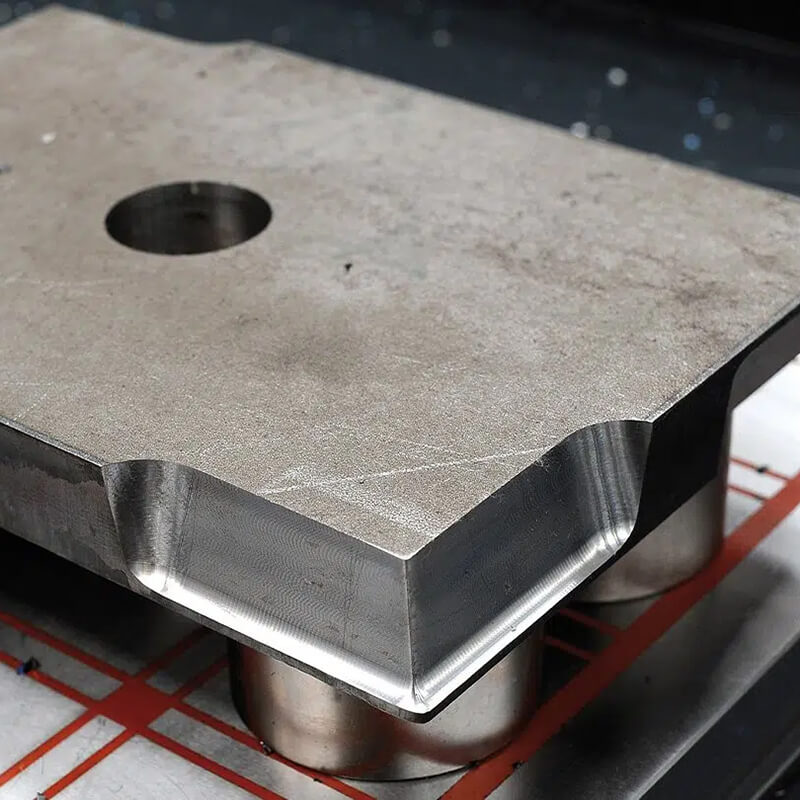

Advanced Milling

Dedicated software upgrades allow special milling operations such as straight slots, special curve slots, countersinking, “Y” and “J” groove, and other special cycles.

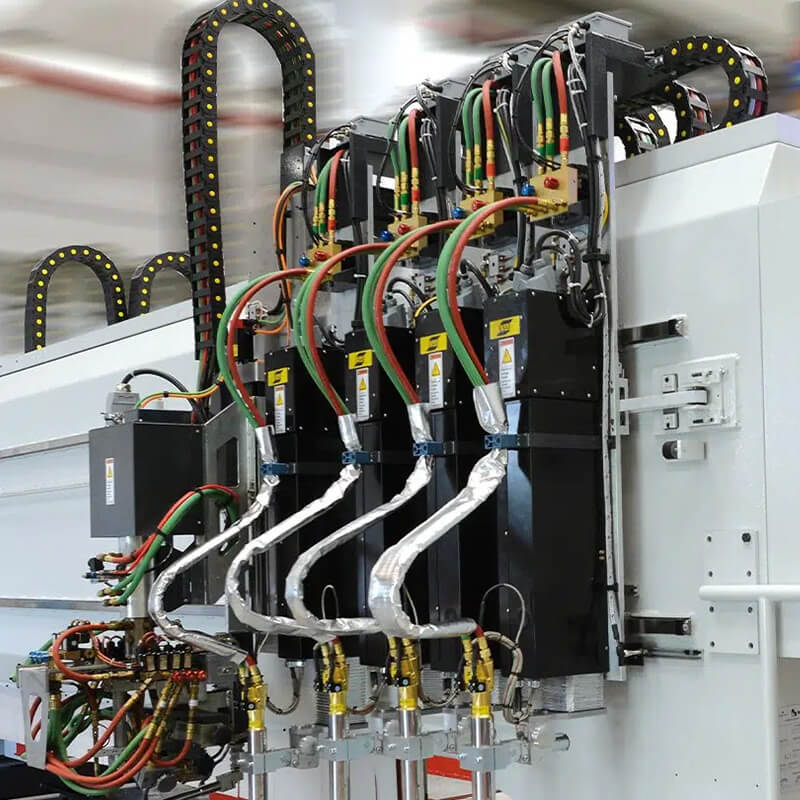

Oxy-Fuel Torches

Gemini systems can be equipped with up to three oxy-fuel cutting torches to cover all manufacturing needs.

HYPERTHERM Plasma Units

The brand new Hypertherm XPR300 or HPR400XD power sources can be supplied for one or two torches for straight or bevel cutting.

HYPERTHERM “TRUE HOLE”

Hypertherm “True Hole” process is available on this model.

Scribing

Scribing operations are available for identification marks, part numbers, bending lines, center locations for positioning and welding. Deeper markings can also be generated so they are viewable after painting/galvanizing.

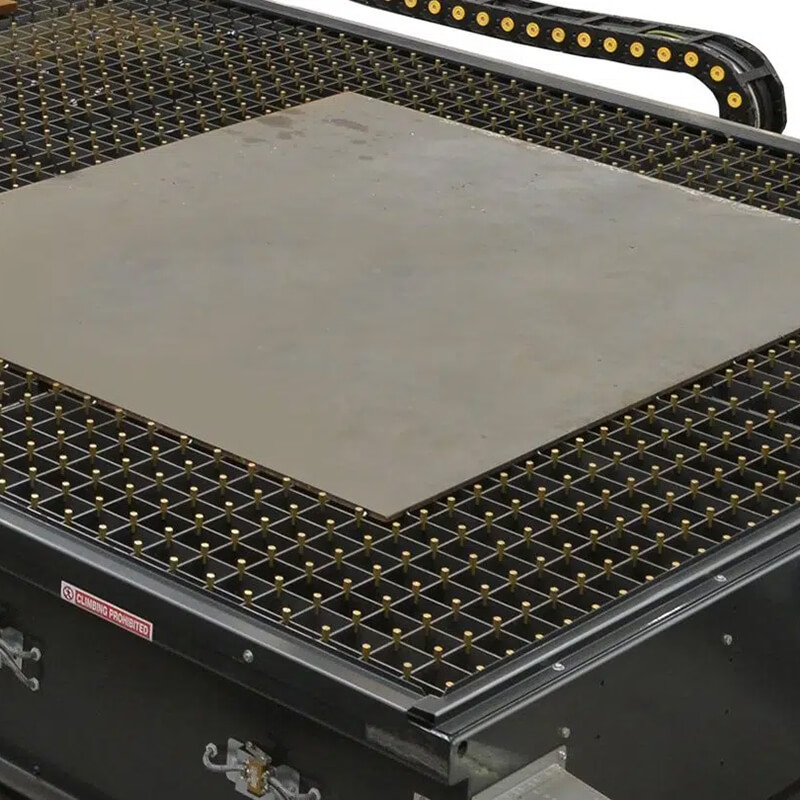

Cutting Bench

The bench is made of a sturdy grid suitable to guarantee the stable positioning of the plate during the processing. The bench is pre-arranged to receive the fume exhaust and filtering system.

Fume Exhaust System

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

Double Gantry System

Gemini systems can be combined in tandem with another Gemini or with our Kronos plate cutting systems to optimize the productivity and floor space with lower costs.

Robotic Unloading

Gemini can be integrared with an independent 4-axis robotic part unloading system to enhance its productivity and automation

Advantages

- Simple floor mounted installation without the need for special foundations.

- Precision laser for plate referencing that automatically rotates the plate nesting program to eliminate the need to square the plate prior to processing.

- Multiple integrated plate clamps rapidly adjust to the plate thickness to reduce the clamping cycle. The clamps rigidly secure the plate to the material bed to eliminate.

- Remote diagnostics are possible through a network connection that allows our service team to perform a system analysis.

Technical Specifications

| GEMINI | Plate size [max.mm] | Plate thickness with plasma [max.mm] | Plasma straight torches [max.no.] | Plasma bevel torches [max.no.] | Plate thickness with oxy-fuel [max.mm] | Plate thickness with oxy-fuel [max.mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max.mm] | Drilling thickness [max.mm] | Spindle power [kW] | Spindle speed [max.RPM] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G25SP | 2540 x 6000 | 80 | 1 | 1 | 100 | 3 | 1 | 6 | 40 | 80 | 15 | 7000 | 4500 |

| G32SP | 3100 x 6000 | 80 | 1 | 1 | 100 | 3 | 1 | 6 | 40 | 80 | 15 | 7000 | 4800 |

| G25HPE | 2540 x 6000 | 80 | 1 | 1 | 100 | 3 | 1 | 24 | 40 (250) | 80 | 15 | 7000 | 4500 |

| G32HPE | 3100 x 6000 | 80 | 1 | 1 | 100 | 3 | 1 | 24 | 40 (250) | 80 | 15 | 7000 | 4800 |

| G36HDE | 3600 x 6000 | 80 | 2 | 2 | 127 | 3 | 2 | 24 | 75 (400) | 127 | 30 | 6000 | 9500 |

| G36XD | 3600 x 6000 | 80 | 2 | 2 | 150 | 3 | 2 | 16 | 80 (400) | 305 | 58 | 4500 | 15000 |

Montfort International

G1P 3T3, Canada