Ficep TIPO B Automatic CNC Punching & Thermal Cutting Systems for Heavy Plates

Punching & thermal cutting of plates

Automatic CNC punching & thermal cutting systems for heavy plates. TIPO B system is one of the most innovative and comprehensive solutions for the fabrication of plates. A CNC punching and thermal cutting system integrates all the typical functions normally required in plate fabrication. The ability to start with raw material and end with the finished part including such operations as drilling, milling, punching, marking, scribing and thermal cutting of the part to the desired size and shape is what makes the TIPO B truly unique.

Types of Processes

- Punching

- Drilling

- Scribing

- Countersinking

- Tapping

- Oxy-fuel cutting

- Plasma cutting

- Marking

Section Shapes

Plates

Main Features

Punching Unit

The punching unit, complete with a 4 positions tool-changer, consists of a hydraulic cylinder designed integrated with hydraulic clamping of the punch and the coaxial stripper.

Drilling Unit

TIPO B can also be equipped with a high speed drilling unit with a 4 positions tool-changer, to perform drilling, tapping, countersinking, scribing and more operations.

Oxy-Fuel Torches

Up to two oxy-fuel torches are available to cover diverse manufacturing needs.

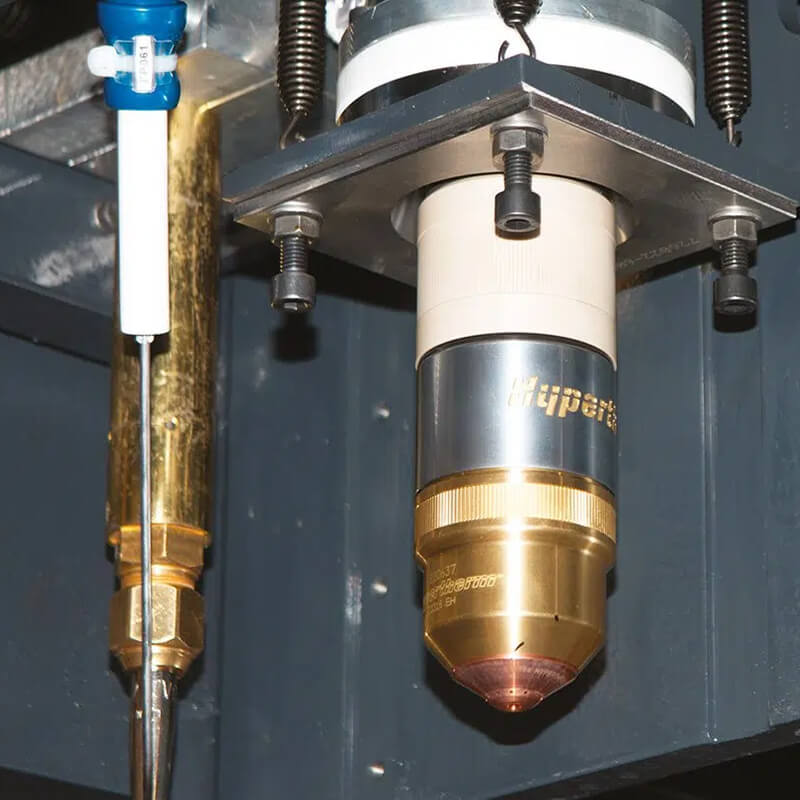

HYPERTHERM Pasma Units

The brand new Hypertherm XPR300 or HPR400XD power source can be supplied for one or two high-definition plasma torches.

Fume Exhaust System

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

Lateral Grippers

The plate is positioned by lateral grippers driven by a precise linear rack and pinion system that locates the plate to the programmed positions.

Plates Handling

The infeed and outfeed conveyors can be extended in order to accommodate longer stock plates. The conveyors are pre-arranged to accommodate cross transfer tables for loading and unloading of plates.

Trap Door

A special trap door can be supplied to unloaded finished parts with a max. size of 500x500mm (19-5/8” x 19-5/8”).

Advantages

- Integration of multiple operations within one CNC work cell.

- Reduced overall footprint and easy material handling.

- Powerful nesting software for material and processing optimization.

- Unloading of the finished parts while the system is processing.

- Remote diagnostics are possible through a network connection that allows our service team to perform a system analysis.

Technical Specifications

| TIPO B | Plate size [max. mm] | Punching nominal force [kN] | Punching tool [no.] | Punching diameter [max. mm] | Punching thickness [max. mm] |

|---|---|---|---|---|---|

| TIPO B164 | 1600 x 3000 | 1000 | 4 | 32 | 25 |

| TIPO B254 | 2540 x 6000 | 1000 | 4 | 32 | 25 |

| TIPO B | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max. mm] | Drilling thickness [max. mm] | Spindle power [kW] | Spindle speed [max. RPM] | Plasma torches [max. no.] | Oxy-fuel torches [max. no.] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| TIPO B164 | 1 | 4 | 40 | 100 | 20,1 | 4000 | 2 | 2 | 8000 |

| TIPO B254 | 1 | 4 | 40 | 100 | 20,1 | 4000 | 2 | 2 | 24000 |

Montfort International

G1P 3T3, Canada