Ficep TIPO G Automatic CNC Drilling, Milling and Thermal Cutting System for Large Plates

Plates drilling, milling and thermal cutting

Automatic CNC drilling, milling and thermal cutting system for large plates. The new TIPO G product line combines the advantages of gantry style plate processors where the plate is stationary with that of systems where the plate is positioned for each operation. The TIPO G features sub-axis spindle positioning so it is not always necessary to unclamp, position a gantry or material and re-clamp the material for each spindle operation. The system integrates thermal cutting (straight and bevel), drilling, milling, scribing, countersinking and more with industry leading accuracy.

Types of Processes

- Drilling

- Scribing

- Milling

- Countersinking

- Tapping

- Oxy-fuel cutting

- Plasma cutting

- Marking

Section Shapes

Plates

Main Features

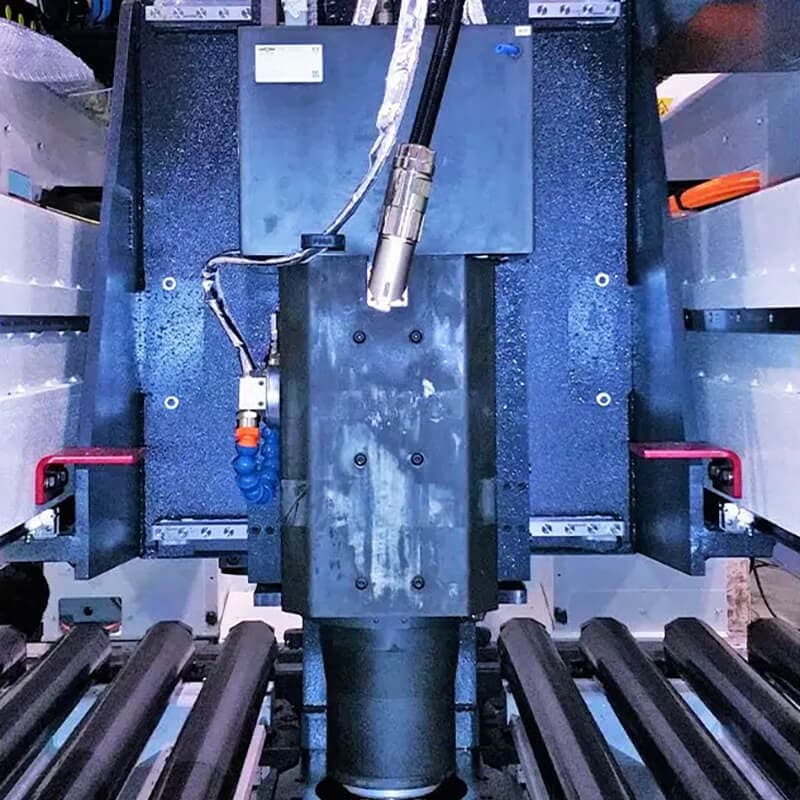

Drilling Unit

The high speed machining spindle allows extremely productive drilling of holes up to 60mm (2-3/8”). For larger holes up to 400mm (15-3/4”) the TIPO G, with sub axis spindle positioning, can mill holes with exceptional accuracy on diameter and concentricity.

Tool Changer

The automatic tool change system is managed by the CNC and is equipped with 24 positions.

Second Drilling Unit

The system can be equipped with an additional drilling spindle with a second 24 positions tool-changer to increase the productivity.

Advanced Milling

Dedicated software upgrades allow special milling operations such us straight slots, special curve slots, countersinking, “Y” and “J” groove, and other special cycles.

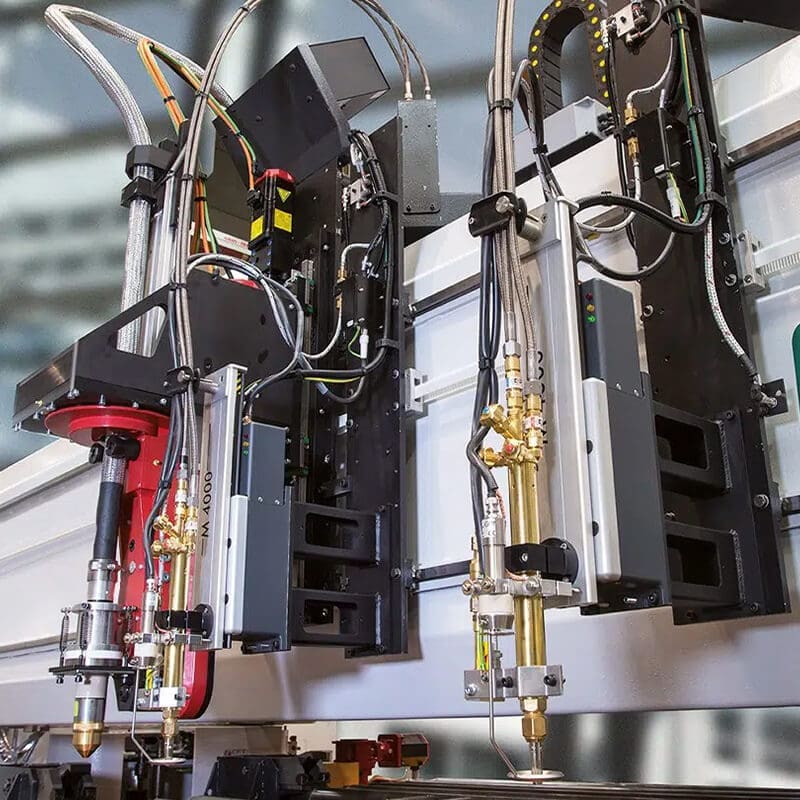

Oxy-Fuel Torches

The system can be equipped with one or two oxy-fuel cutting torches to cover all manufacturing needs.

HYPERTHERM Plasma units

The brand new Hypertherm XPR300 or HPR400XD power sources can be supplied for one or two torches for straight or bevel cutting.

Lateral Grippers

Lateral grippers, driven by a precise rack and pinion system along fix rails, are utilized to position the plate in the “X” axis. The lateral grippers, in conjunction with hydraulic material clamping, are employed to reposition longer plates, expanding the size of stock plates that can be processed.

Material Supports

An underside material support system is positioned in coordination with the movement of the drill spindle. This stabilizes the plate during all spindle operations.

Fume Exhaust System

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

Plates Handling

The infeed and outfeed conveyors can be extended in order to accommodate longer stock plates. The conveyors are pre-arranged to accommodate cross transfer tables for loading and unloading of plates.

Trap Door

A special trap door can be supplied to unloaded finished parts with a max. size of 500x500mm (19-5/8” x 19-5/8”).

Advantages

- Sub-axis spindle positioning permits all operations to be performed without moving the plate.

- Automatic piece unloading makes the TIPO G ideal for the production of small and medium size plates.

- Special hold-downs integrated into the drilling units keeps the plate in position during processing to avoiding vibrations that could comprise quality and tools life.

- Remote diagnostics are possible through a network connection that allows our service team to perform a system analysis.

Technical Specifications

| TIPO G | Plate size [max.mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max.mm] | Drilling thickness [max.mm] |

|---|---|---|---|---|---|

| TIPO G25LG | 2540 x 6000 | 1 | 24 | 40 (250) | 100 |

| TIPO G31LG | 3100 x 6000 | 2 | 24 | 44/60 (400) | 100 |

| TIPO G | Spindle power [kW] | Spindle speed [max. RPM] | Plasma straight torches [max. no.] | Plasma bevel torches [max. no.] | Oxy-fuel-fuel torches [max. no.] |

|---|---|---|---|---|---|

| TIPO G25LG | 15 | 7000 | 1 | 1 | 2 |

| TIPO G31LG | 26 | 7000 | 2 | 2 | 2 |

Montfort International

G1P 3T3, Canada