Print this page

Ficep E-LEXINGTON Laser Projector for Robotic Welding

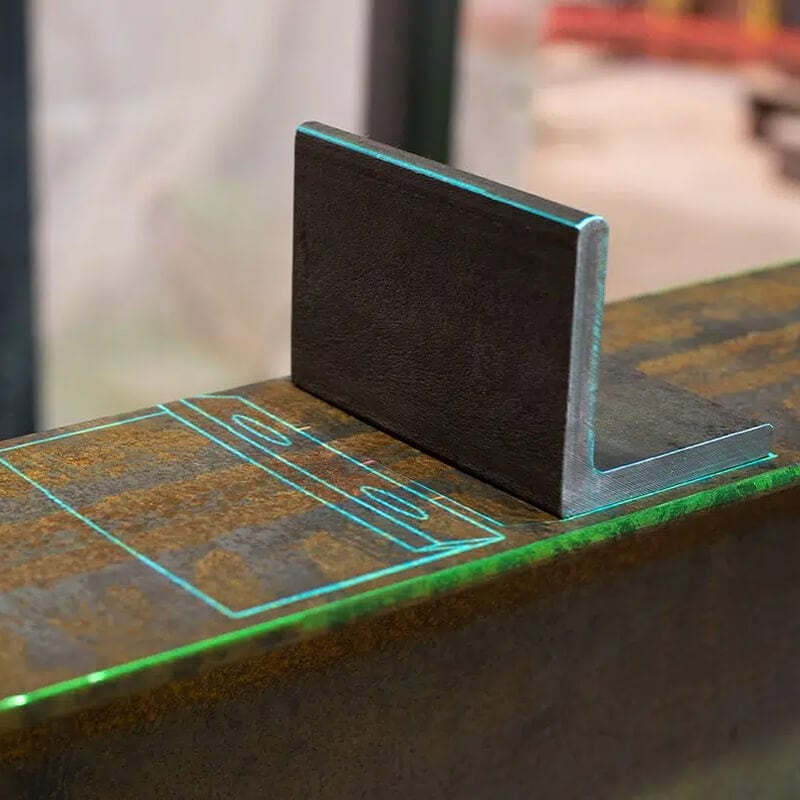

For decades the structural steel fabrication industry has been challenged with finding, training and retaining employees to produce accurate layout in a productive manner. The E-LEXINGTON eliminates the need for a layout person to read a drawing, decipher the information, then use a steel tape, square and soap stone to mark the relative surfaces to indicate locations, welding codes and any additional pertinent information.

Types of Processes

Welding

Section Shapes

Beams

Angles

Flats

Main Features

Laser Profile Identification

The laser system locates the section and the zero point for subsequent layout projection.

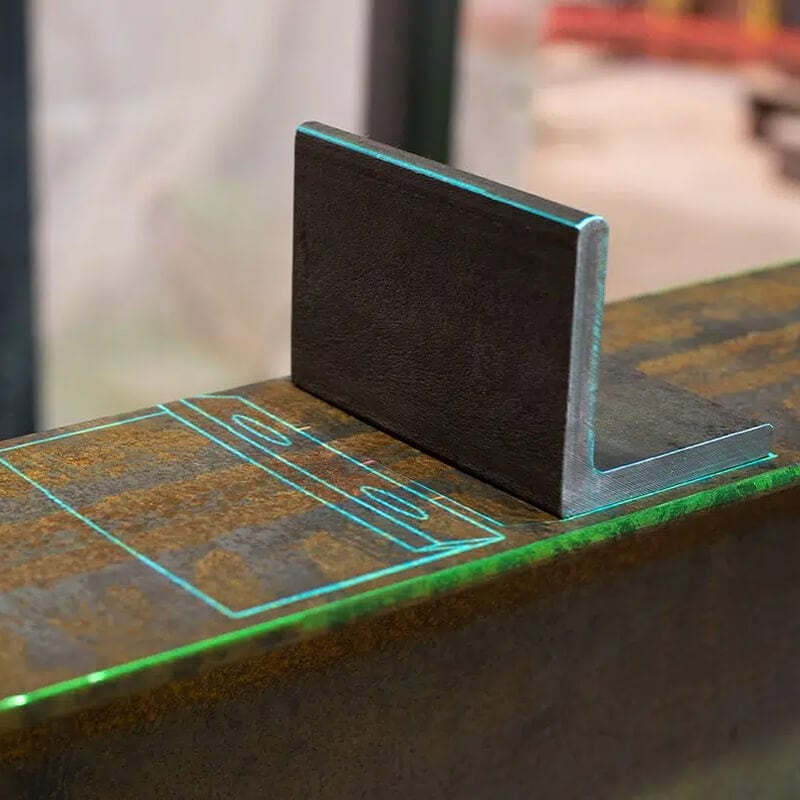

Detail item Projection

The required layout locations on the main member of the detail items are projected on the structural steel section.

Detail Item Tack Weld

Using the designated layout location, which was downloaded from the 3D model, the welder tacks the detail item on to the main member.

Advantages

- Reduces the requirement for skilled layout staff.

- Frees up existing shop space that was used previously for generating manual layout.

- Substantially increase your productivity and reduce your fabrication errors.

Montfort International

2500 av. Watt, Quebec City (Qc),

G1P 3T3, Canada

G1P 3T3, Canada

1-800-463-6668

info@montfort-international.com