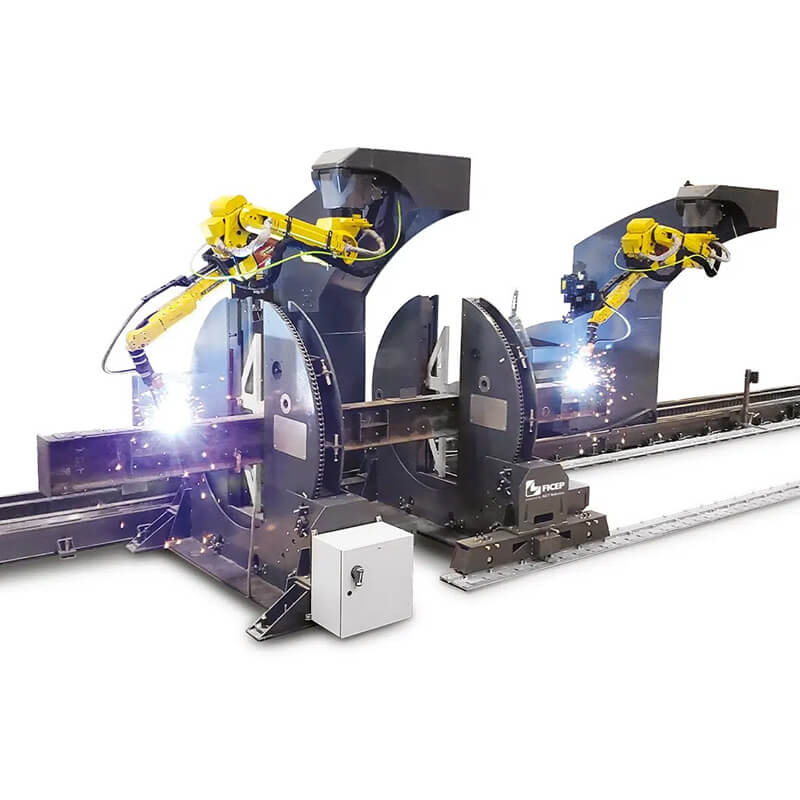

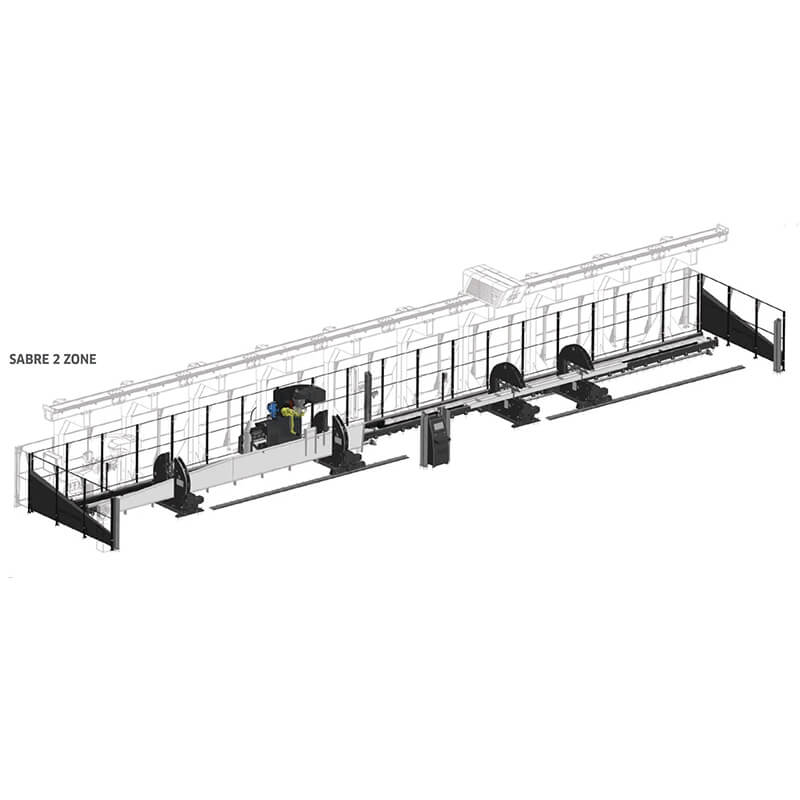

Ficep SABRE Automatic Welding Robot

Robotic welding

SABRE performs the robotic welding of all secondary components on the main member. The operator is tasked with the loading of the section after the detail has been tack welded at the proper locations into the automated welding positioners. As structural steel is subject to typical rolling tolerances the SABRE automatically senses all the relative surfaces so the robotic welding process can be generated without any manual manipulation.

Types of Processes

Welding

Section Shapes

Beams

Angles

Flats

Main Features

Detail Item Probing

The robot probes the actual location of the tacked detail items before commencing the automatic welding process.

Two Zones System

When a tandem system is employed the operator can tack the detail elements on one positioner while the robot is welding the previously tacked member.

Positioners

Welding positioners can be integrated in the system to eliminate the need for the operator to rotate the section if required.

Advantages

- Greatly reduces the shop space required for fitting and welding.

- Solves the challenges of hiring, training, and retaining skilled layout employees.

- Substantially increases the productivity and lowers the cost per ton.

Montfort International

G1P 3T3, Canada