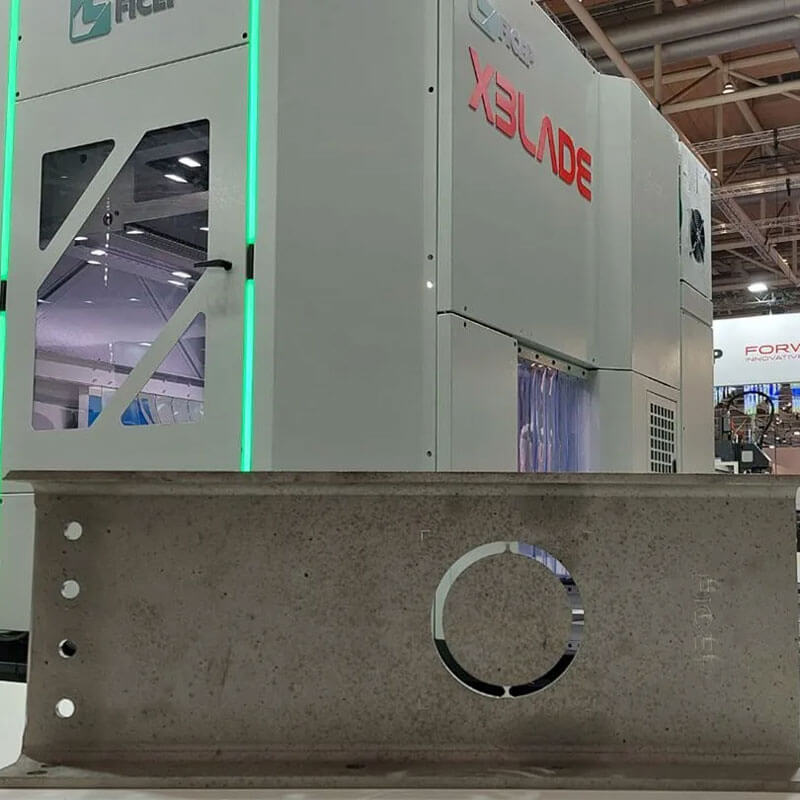

Ficep XBLADE Machining Center for Automatic CNC Single Spindle Drilling, Milling and Sections Cutting

Profiles Drilling and Cutting

Ficep XBLADE machining center for automatic CNC single spindle drilling, milling and sections cutting. Designed to streamline the manufacturing process, XBLADE boasts automated capabilities for drilling, tapping, milling, and cutting steel construction beams of various sizes.Ficep XBLADE Machining Center

XBLADE, the latest addition to FICEP machine range meticulously crafted by our team of engineers to meet the diverse needs of our customers. This innovative machine is born at the intersection point of advanced technology, versatility, and precision, offering a comprehensive solution for processing small profiles and executing complex operations within a standalone working cell. Designed to streamline the manufacturing process, XBLADE boasts automated capabilities for drilling, tapping, milling, and cutting steel construction beams of various sizes.

Types of Processes

- Drilling

- Tapping

- Milling

- Countersinking

- Scribing

- Disc sawing

Section Shapes

Beams

Angles

Flats

Channels

Square tubes

Rectangular tubes

Main Features

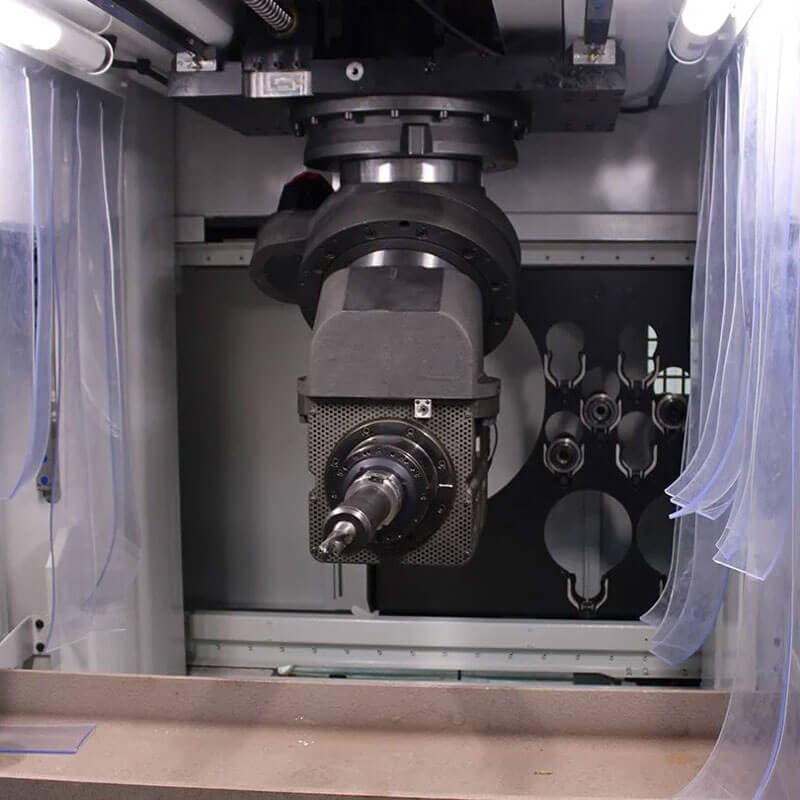

Double-Axis Rotary Head

The working head features two rotary axes positioned at a 45° angle, enabling operations on double inclined planes without the need for profiled tools. The head is powered by a robust 32 kW (S1) three-phase asynchronous motor, delivering 100% power to the tool for complex drilling, tapping, and milling operations.

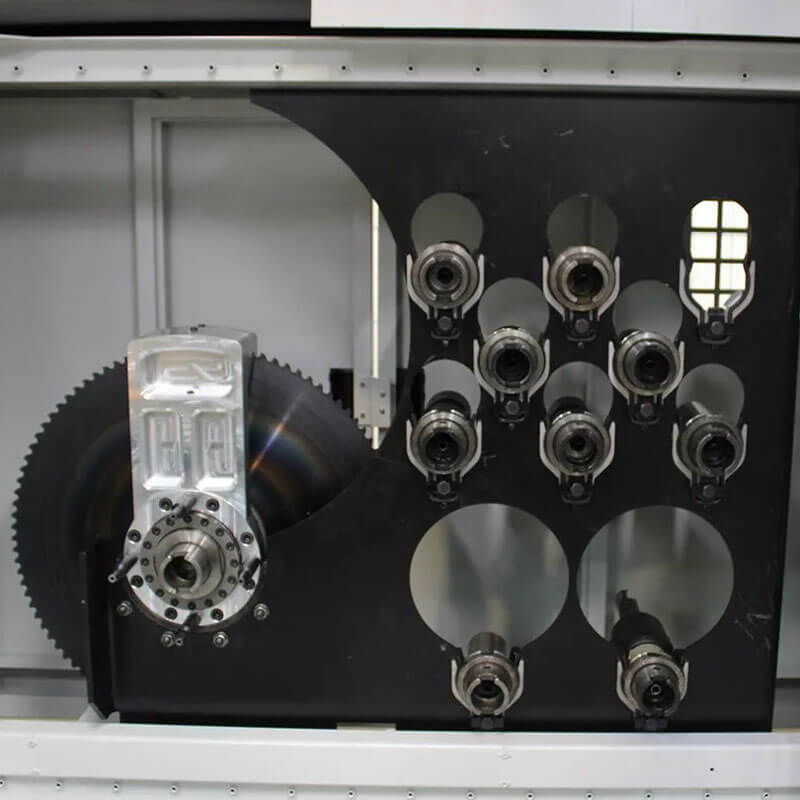

Electro-Spindle Cutting Tool

XBLADE is designed with an innovative cutting tool equipped with a 560 mm diameter disc cutting blade capable of processing all five sides of the profile. A patented system is employed to increase cutting torque, enhancing overall performance.

Automatic Tool Rack

Equipped with an automatic tool rack featuring eight positions for standard tools, two positions for large tools, and one position dedicated to the 560 mm disc blade.

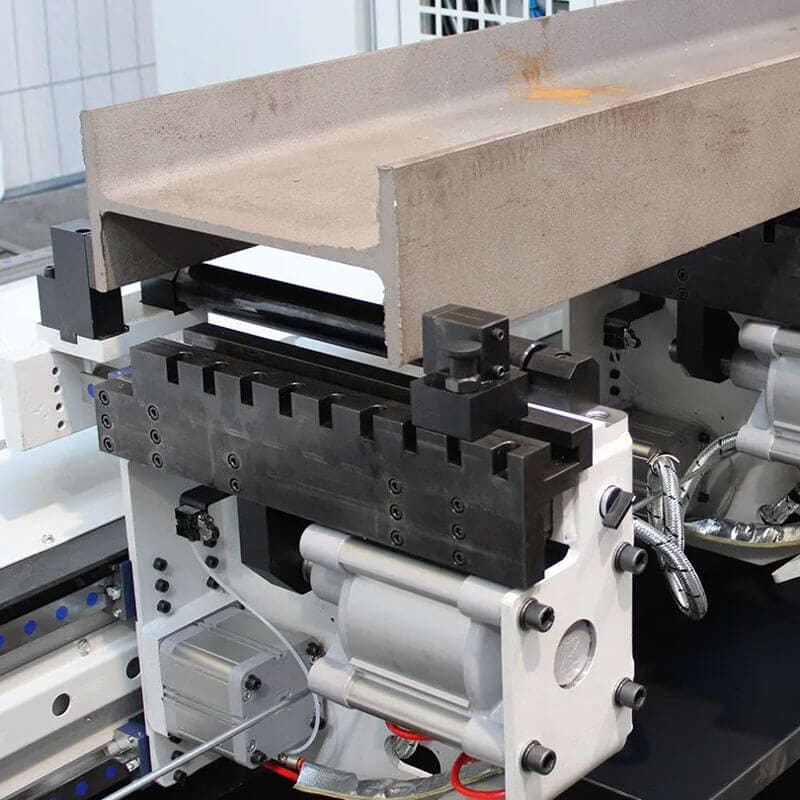

Section Clamping System

Independently mobile vices can be positioned along the X-axis and locked in place by a pneumatic clamping system. Rollers facilitate the handling of material during processing, allowing the rearrangement of vices.

Compact Design

Thanks to the compact design with integrated electrical cabinet, air conditioning, and spindle fluid cooling systems, this configuration optimizes workshop space and requires minimal operator supervision.

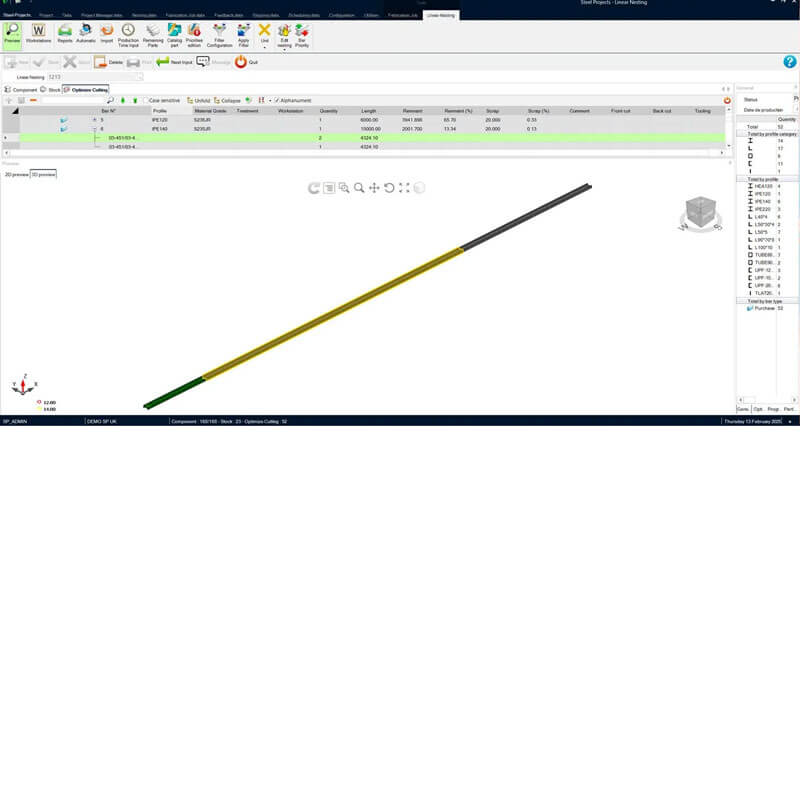

Profile Nesting

Profile nesting can be programmed and optimized through Ficep XBLADE Office Technology software. The embedded CAM software generates the ISO program, facilitating the launch of the working cycle.

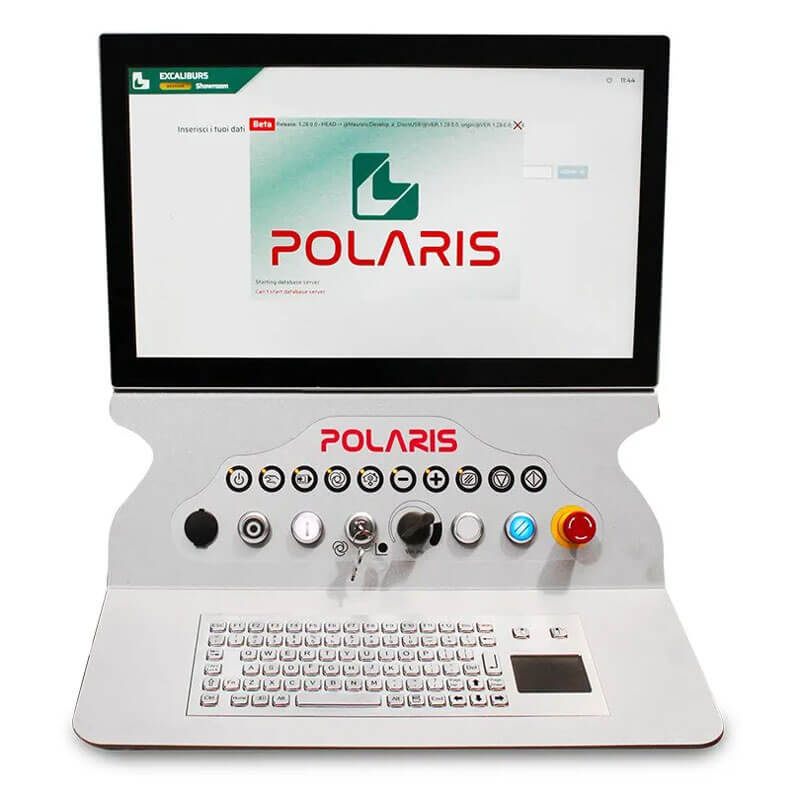

POLARIS

Open CNC Technology enhances CNC and PC integration via high-speed fiber optic communication. Featuring a fanless design for reliability, IP65 protection, and a 22″ capacitive multi-touch display, it includes 2D/3D visualization, nesting, and remote assistance with Windows 10 IoT.

Advantages

- The machine features a modular base that facilitates the movement of the frame supporting the Y-axis cantilever structure.

- Equipped with a spindle capable of positioning in any direction in space, thanks to double rotating universal head.

- X and Z-axes movements are supported by roller runner blocks and servo motors, ensuring smooth and accurate operation.

- XBLADE utilizes brushless motors, high precision rack and pinions, and recirculating ball screws command systems for optimal performance.

- 2 inclined rotary axes, one vertical axis and the other positioned at 45°, both driven by a servo motor, through a belt and pulleys with a harmonic gearbox, allowing the positioning of the spindle on double-inclined surfaces.

Technical Specifications

| XBLADE Automatic CNC single spindle drilling, milling and cutting line for sections |

301 XB5 |

|---|---|

| Section contained in area [min. mm] | 30 X 30 |

| Section contained in area [max. mm] | 305 x 305 - 460 x 305* *with processing operation possible on 2 sides (2 heads, datum line side) |

| Drilling / Sawing heads [no | 1 |

| Drilling tools per head [no.] | Drilling: 8 Milling: 2 (max. D200) Cutting: 1 |

| Drilling diameter [max. mm] | 50 |

| Disc saw diameter [mm] | 560 |

| Spindle power [S1 kW] | 32 |

| Spindle speed [max. RPM] | 3500 |

| CNC axes [no.] | 5 |

| Base module mass [kg] | 7000 |

| Standard configuration mass [kg] | 16000 |

Montfort International

G1P 3T3, Canada