HE&M Saw H105M Semi-Automatic Horizontal Pivot Bandsawing Machine

Blade : 15'0″ x 1,25″ x 0,042″

Motor : 7,5 HP

Operation: Semi-automatic

Standard Features

Easv View Console

The Control Console is located in an Easy View style control on a gooseneck mount, and can be pivoted for operator convenience.

24" Solid Discharge Table

A standard 24" solid discharge table provides easier handling after the cut. The table is 24" in length and is fully coolant panned.

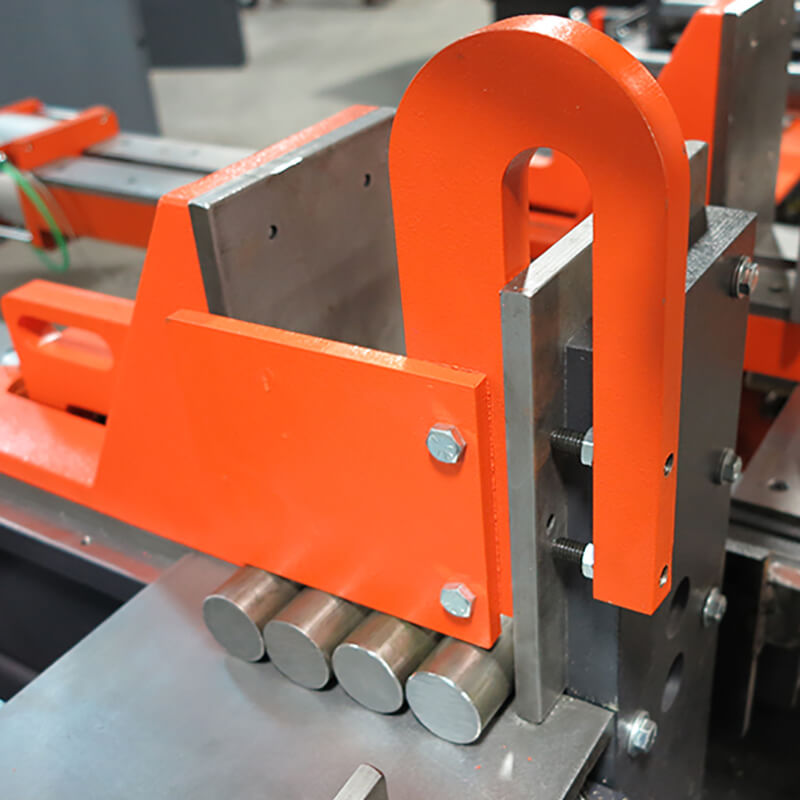

Adjustable Main Vise

The saw vise slides on the vise ways. When the clamp is engaged, the air powered short stroking vise is pulled toward the fixed wear plate, clamping the material in place to ensure accurate cuts. The clamping pressure is easily adjusted to clamp various materials .

Hold Down Fixture

A hold down fixture also aids in the clamping of multiple pieces of material in a single row.

Adjustable Feed Rate

The saw arm Feed Rate can be adjusted from zero to 3 inches per second.

Adjustable Cut Force

Cutting pressure/ force can be adjusted for effective metal removal rates.

Push Button Blade Speed

Blade speed can be adjusted with an infinitely variable speed drive from the console with push button controls. The blade speed is shown on the console with LED Readout.

Manual Adjustable Guide Arm

The Guide Arm is adjusted manually to help stabilize the blade and reduce vibration, providing a better cutting surface.

Carbide Blade Guides

A blade guide system is composed of side and back guides, which are flat carbide inserts.

Blade Brush

A shaft-driven Blade Brush is standard for positive removal of metal chips that lodge in the blade gullets. This system ensures a cleaner blade, more accurate cuts, and prolonged blade life.

Built-In Flood coolant svstem

The saw has a totally built-in coolant system with sealed coolant pump. The coolant is dispensed through the guide arms on both sides of the cut.

Safety Emergency Stop Cut-Off Switch

The saw is equipped with a safety Emergency Stop cut-off switch. This allows the operator to closely monitor the cutting process and quickly stop it if needed.

Panic Stop

The Panic Stop haults all automatic functions.

Broken Blade Indicator

The saw will automatically shut off if the blade breaks, shown by the Broken Blade Indicator.

Other Features

- 220V/440V/3PH Electrical Motor Requirement

- 85 PSI, 4-6 CFM Minimum Air Requirement (Equipped w/ Air Filter/Lubricator)

Available Optional Features

Reduced Capacity Top Clamp - Main Vise

An Optional reduced capacity top clamp can be added to the main vise for vertical clamping of structural shapes.

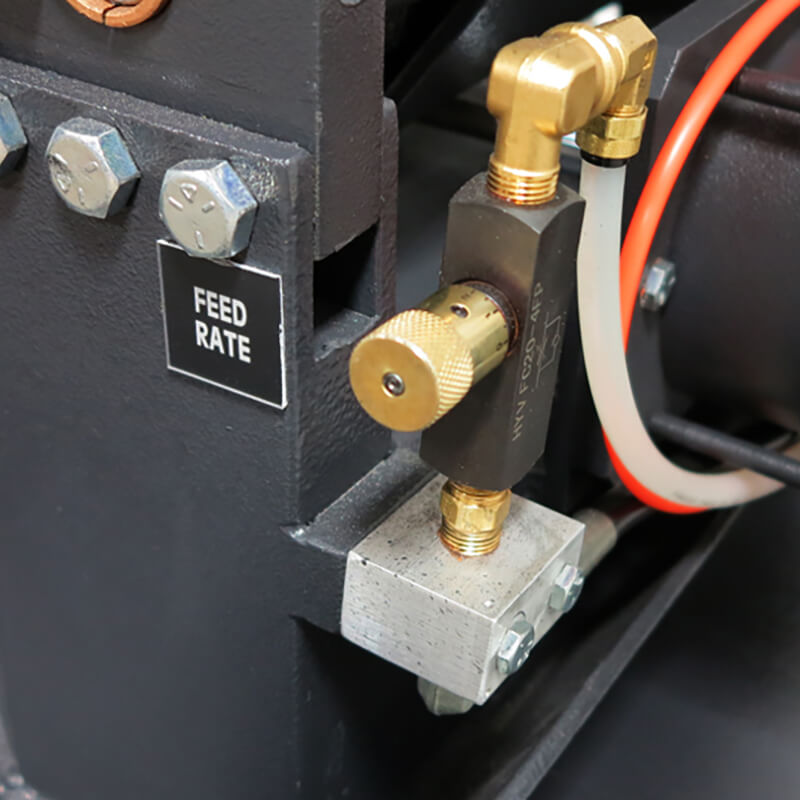

Spray Mist Lubrication

The optional spray mist system lubricates the blade with a mist that is adjustable at a rate of 4 - 200 pulses per minute, pushing the mix of oil/air out of the delivery line to the nozzle.

Chip Auger svstem

An Optional Chip Auger removes chips from the cutting area into an easy-to-empty container. Chips and coolant are automatically separated into two different containers.

5' or 10' Idle Roller load Table & Idle Roller Stock Tables

Optional 10' Roller Load Table, and 5' or 10' optional idle roller tables with 12" centers are available for material handling. The tables are noncoolant panned and height adjustable to be "trued-in" with the saw. They are designed to move even the large bars with ease and accuracy.

Cut Watcher® System

An Optional patented Cut Watcher@ system monitors the cut for squareness to a pre-set deviation value. The system shuts down the saw when the pre-set value is exceeded.

Autres options disponibles

- Light Clamping Pressure

- Single-Phase Voltage

Montfort International

G1P 3T3, Canada