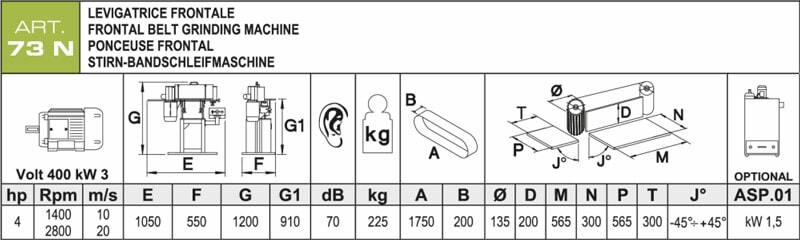

Aceti ART.73N Frontal Belt Grinding Machine

Technical Specifications

General Technical Info

| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 3,3 - 2,6 ( 4,5 - 3,5 ) | kW ( hp ) |

| Motor speed | 2800 - 1400 | tr/min |

| Acoustic emission | 70 | dB |

| Overall dimension (Width x Depth x Height) | 1050 x 550 x H. 1200 | mm |

| Weight standard machine | 225 | kg |

Belt Grinder Unit

| Abrasive belt dimension (wide x length) | 200 x 1750 | mm |

| Peripheral speed | 20 - 10 | m/sec |

| Dimension of working plane (behind abrasive belt) | 565 x 300 | mm |

| Driving wheel dimension | ø 135 | mm |

| Orientable belt grinding arm | 0 | ° |

| Support table dimension | 565 x 300 | mm |

| Support table revolution | - 45 ÷ + 45 | ° |

Standard Equipment

CE Stamp of Compliance

- Machine with CE conformity mark made respecting the requirements of the most recent directives concerning it.

- Machine complete with instruction manual complete with CE conformity certificate, test sheet and exploded view with relative spare parts list.

- Machine equipped with a set of service keys suitable for the adjustment and maintenance of the machine.

Base

Strong base with anti-vibration rubbers at the base and a useful shelf for tools inside.

Electrical panel

Low voltage electric controls with padlock device integrated in the main electric switch.

Electronic brake card

Emergency stop with electronic motor braking with safety anti-reset function.

Motor

Motor 2 speeds

Type of work

Two types of work:- Plan for special support of the surface plate processing:tiltable with graduated indicator -45 ° to + 45 ° and intermediate positions height adjustable by means of handwheel for the full utilization of the cutting surface of the abrasive tape.- special support plan for working on rubber wheel:tiltable with graduated indicator -45 ° to + 45 ° and intermediate positions adjustable height for the full utilization of the cutting surface of the abrasive tape.

Work surface

Behind the abrasive tape has a durable floor in abutment replaceable steel over time.

Rubberized grooved wheel

Rubberized, grooved and balanced drive wheel for better drag of the abrasive belt.

Abrasive belt

Abrasive belt mounted on the machine ready for use.

Belt grinder cover

Carter sander with predisposition connection system.

Montfort International

G1P 3T3, Canada