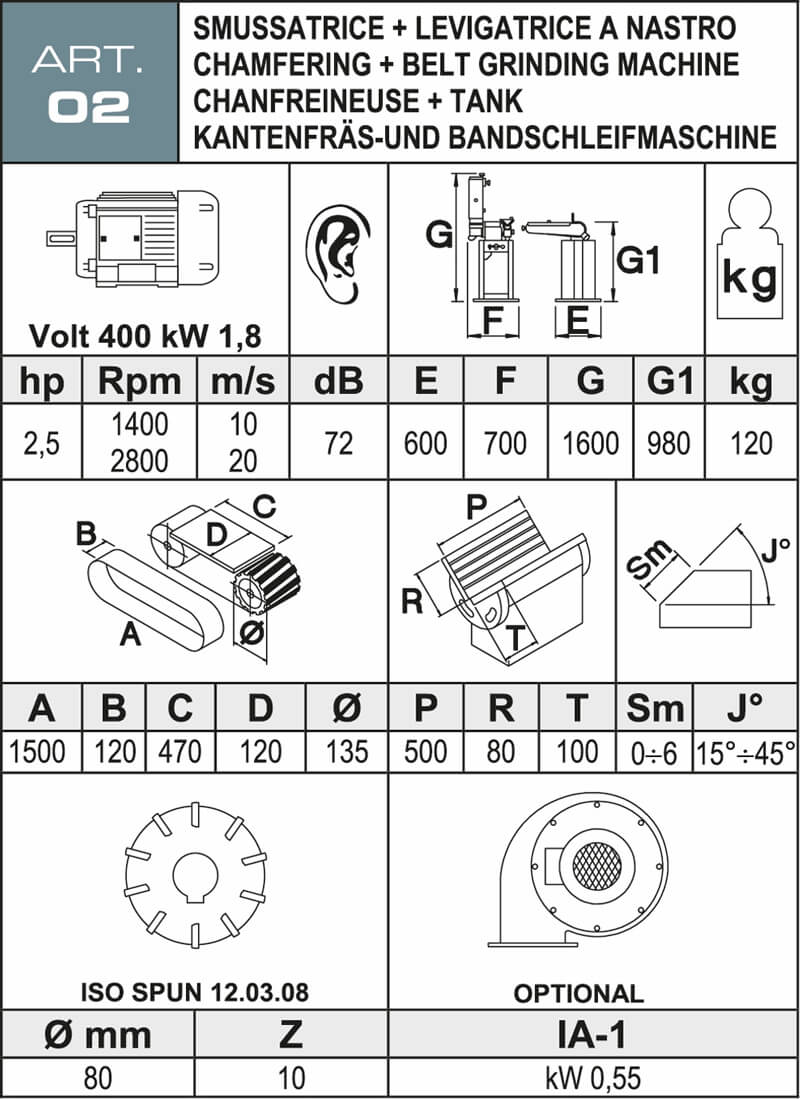

Aceti ART.02 Swing Belt Grinding and Bevelling Machine

Technical Specifications

General Technical Info

| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 1,9 - 1,1 ( 2,5 - 1,5 ) | kW ( hp ) |

| Motor speed | 2800 - 1400 | tr/min |

| Acoustic emission | 72 | dB |

| Overall dimension (Width x Depth x Height) | 700 x 600 x H. 1600 | mm |

| Weight standard machine | 120 | kg |

Chamfer - Bevel Unit

| Bevel dimension (diagonal) | 0 ÷ 6 | mm |

| Bevel angle | 15 ÷ 45 | ° |

| Milling cutter diameter | ø 80 | mm |

| Quantity of widia insert milling cutter | 10 | No. |

| Widia insert type/code | SPUN 12 03 08 | ISO |

| Support table dimension | 100 x 500 | mm |

| Peripheral speed | 12 - 6 | m/sec |

Belt Grinder Unit

| Abrasive belt dimension (wide x length) | 120 x 1500 | mm |

| Peripheral speed | 20 - 10 | m/sec |

| Dimension of working plane (behind abrasive belt) | 120 x 470 | mm |

| Driving wheel dimension | ø 135 | mm |

| Orientable belt grinding arm | 0 ÷ 90 | ° |

Standard Equipment

CE Stamp of Compliance

- Machine with CE conformity mark made respecting the requirements of the most recent directives concerning it.

- Machine complete with instruction manual complete with CE conformity certificate, test sheet and exploded view with relative spare parts list.

- Machine equipped with a set of service keys suitable for the adjustment and maintenance of the machine.

Base

Strong base with anti-vibration rubbers at the base and a useful shelf for tools inside.

Electrical panel

Low voltage electric controls with padlock device integrated in the main electric switch.

Electronic brake card

Emergency stop with electronic motor braking with safety anti-reset function.

Motor

Motor 2 speeds

Orientable arm sander

Arm sander adjustable from 0 ° to 90 ° and intermediate positions.

Type of work

Three types of processing, in plan with support, on tyred wheel, on tyred wheel with support.

Work surface

Behind the abrasive tape has a durable floor in abutment replaceable steel over time.

Rubberized grooved wheel

Rubberized, grooved and balanced drive wheel for better drag of the abrasive belt.

Abrasive belt

Abrasive belt mounted on the machine ready for use.

Belt grinder cover

Carter sander with predisposition connection system.

Hardened guide coating

Rectified and grooved guides with hardening treatment for a prolonged friction resistance.

Axial movement

Axial displacement for full use of the cutting surface of the inserts.

Variable chamfer angle

Chamfering guide with index for bevels from 15 ° to 45 °.

Handwheel

Handwheel for chamfer dimension adjustment.

Miller body

Milleler body complete with 10 tungsten carbide inserts.

Anti-spark repair

Transparent protection arrester with friction joint.

Optional Equipment

IA-1: Dust Extractor - One Connection

DUST EXTRACTOR kit with one suction mouth: complete of dust filter bag in flexible aluminum pipe and hose clamps. The extractor is mounted inside the base and wired to the electrical panel.TECHNICAL FEATURES- Motor: Volt 400 - Rpm 2800 - kW 0,55- Max flow rate: 1.000 m3 / h- Max total pressure: 85 mm H2O

Montfort International

G1P 3T3, Canada