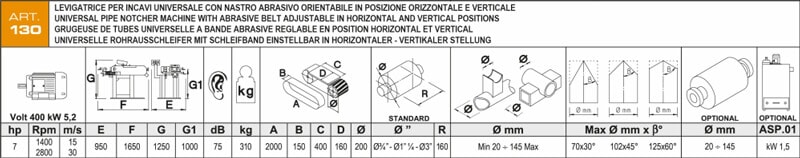

Aceti ART.130 Pipe Notching Machine for Tube Ends and Logitudinal Grooving

Technical Specifications

General Technical Info

|

Power supply |

400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 5,0 - 3,0 ( 6,8 - 4 ) | kW ( hp ) |

| Motor speed | 2800 - 1400 | tr/min |

| Acoustic emission | 75 | dB |

| Overall dimension (Width x Depth x Height) | 950 x 1650 x 1250 | mm |

| Weight standard machine | 310 | kg |

Pipe Notcher

| Abrasive belt dimension (wide x length) | 150 x 2000 | mm |

| Peripheral speed | 30 - 15 | m/sec |

| Dimension of working plane (behind abrasive belt) | 160 x 400 | mm |

| Driving wheel dimension | ø 200 | mm |

| Pipe diameter | ø 20 ÷ ø 145 | mm |

| Angle of pipe notcher | -30 ÷ 90 ÷ +30 | ° |

Standard Equipment

CE Stamp of Compliance

- Machine with CE conformity mark made respecting the requirements of the most recent directives concerning it.

- Machine complete with instruction manual complete with CE conformity certificate, test sheet and exploded view with relative spare parts list.

- Machine equipped with a set of service keys suitable for the adjustment and maintenance of the machine.

Base

Strong base with anti-vibration rubbers at the base and a useful shelf for tools inside.

Electrical panel

Low voltage electric controls with padlock device integrated in the main electric switch.

Electronic brake card

Emergency stop with electronic motor braking with safety anti-reset function.

Motor

Motor 2 speeds

Head of the Machine

Machine head can be swiveled in a horizontal position for notching at the head of the tube and in a vertical position for notching along the length of the tube.

Vice

Variable angle vice with graduated indicator from 30 ° to 90 ° for notching at the head of the tube.Bidirectional vice movement right from 90 ° to + 30 ° and left from 90 ° to -30 ° for notching at the head of the tube. Double vice with 0 ° angle for grooves along the length of the tube. Self-centering vice for round and square tubes. Vice with end stop device. Side sliding vice for the complete use of the abrasive belt surface.

Rubberized grooved wheel

Rubberized, grooved and balanced drive wheel for better drag of the abrasive belt.

Horizontal surface

Large horizontal surface for general deburring and sanding operations.

Graphite

Present behind the sanding belt the canvas graphite to reduce friction and heat development.

Contact roller

Nr. 3 contact rollers for notching pipes from Ø 3/4 "- 1 1/4" - 3 ". Fast and reliable replacement of contact rollers thanks to safety screws. Drawings for the construction of the contact rollers included in the instruction and use manual.

Abrasive belt

Abrasive belt mounted on the machine ready for use.

Belt grinder cover

Carter sander with predisposition connection system.

Anti-spark repair

Transparent protection arrester with friction joint.

Montfort International

G1P 3T3, Canada