Aceti ART.97 Dry Operation Belt Grinding Machine for Flat Surfaces

Technical Specifications

| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 5 ( 6,5 ) | kW ( hp ) |

| Motor speed | 1400 - 2800 | tr/min |

| Overall dimension (Width x Depth x Height) | 1250 x 870 x H. 1850 | mm |

| Weight standard machine | 570 | kg |

| Quantity of abrasive belt | 1 | No. |

| Abrasive belt dimension (wide x length) | 220 x 1750 | mm |

| Peripheral speed | 6 - 12 | m/sec |

| Dimensions of grooved rubberized driving wheel (wide x diameter) | Ø80 x 220 | 60 | mm |

| Belt conveyor dimension | 220 x 2350 | mm |

| Feeding speed of workpiece | min. 1 ÷ max. 10 | m/min |

| Workpiece thickness allowed | min. 1 ÷ max. 125 | mm |

| Workpiece length allowed | min. 120 ÷ max. 6000 | mm |

| Workpiece width allowed | max. 220 | mm |

Standard Equipment

Tensioning of the abrasive belt

Low tension electrical panel

Electric motor with electronic brake

Adjustable feed speed

Position indicator

Anti-vibration feet of leveling

Rubberized and grooved contact wheel

Abrasive belt

CE Stamp of Compliance

Optional Equipment

INV.97: Inverter of speed adjustment of belt grinding unit

Extra charge for the addition of the inverter for the electronic adjustment of the abrasive belt speed from 150 to 3000 rpm and of the electric panel equipped with potentiometer, digital display and electric panel cooling filters. The inverter allows the operator to adjust the grinding speed most suited of the type of material and of the finishing level to be obtained.

RUL.97: Roller table: module of 1,5 m

Roller table of workpieces support at entrance and/or exit adjustable with four self-leveling feet. It is equipped with rubber coated rollers to avoid damaging the machined parts. It is complete with drainer to contain the coolant and return it to the tank in addition to keeping the working environment clean.

CODIV: Contact wheels with different rubberizing

It is possible to mount different contact wheels into the machine according to the types of machining to be performed. We can supply smooth rubber wheels, grooved with different types of grooves, different hardness of rubber coating (Shore) as well as coatings in different materials (black vulcanized rubber, vulkollan etc.).

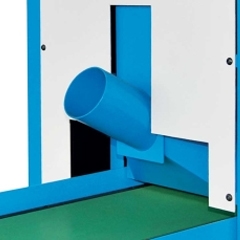

ASP.01-HP2: Dust extractor by cyclone system

Wheeled dust extractor with cyclone system. It is built entirely of steel and has no dust filter bag. The suction takes place by means of the centrifugal force generated by the cyclone which conveys the dust into the underlying steel drawer that collects and holds it. In the case of dry machining it is necessary to connect the machine to a strong vacuum cleaner such as this which keeps the conveyor belt clean from the emery.

Consumables

Abrasive belt for wet working. Various grains: P36÷P400

'Scotch-brite' belt for wet working. Various grains.

Montfort International

G1P 3T3, Canada