HR Series Vibratory Tribofinishing Machine

The HR is a heavy duty machine that can be customized with a wide variety of standard and special options that gives the customer a full range of processing possibilities – from minimal human involvement to a fully automatic system for a hands off operation.

Tribofinishing

The workhorse of the Spiratron® family of vibratory finishing machines, the HR Series has evolved since its original patent notoriety of being the first round bowl internal separation machine. The HR is a heavy duty machine that can be customized with a wide variety of standard and special options that gives the customer a full range of processing possibilities – from minimal human involvement to a fully automatic system for a hands off operation.

Features

- Heavy duty Welded Steel Construction

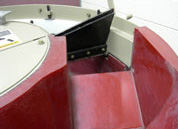

Main building component of the bowl is a certified pressure vessel tank head. - Cast Polyurethane Liner

Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas. - “U” Shaped Straight or Curved Wall Processing Bowl

- Mounted to Non-Vibrating Base

- Premium Efficiency, Ball Bearing, Cast Iron Motor

TEFC, 1800 RPM, 230/460V - Water-Driven Compound System

Model Details

HR-3 SL/CL

- On/Off Switch

- Water Driven Compound System

- Grease Drive System

- Manual Lever Gate

- Internal Stainless Wrap Screen

HR-5 SLT/CLT

- Semi-Automatic Control Panel

- Water Driven Compound System

- Digital Process Timer

- Manual Lever Gate

- Internal Stainless Wrap Screen

- Grease Drive System

HR-11 SPT/CPT (& Larger)

- Semi-Automatic Control Panel

- Water Driven Compound System

- Digital Process Timer

- Recirculating Oil Lube Drive System

- Pneumatic Gate

- Internal Stainless Wrap Screen

HR Series Accessories

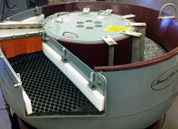

HR Series Machines are vibratory finishing machines that can be customized from a basic stand alone vibratory machine, into a complete multi-featured finishing cell. The options can be single add-ons or very complex system additions to the machine to ensure that they operate flawlessly and continuously to meet the customers needs.

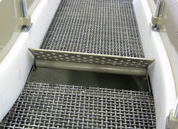

Screen Options

Bar Type Media Classification Screen

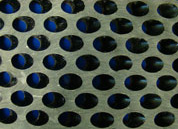

Precision Laser Cut Plate Screen

Reverse Angle Hole Screen

Urethane Bar Screen

Conveyor Options

Dip Tank with Dragout Conveyor System

In Feed and Transfer Conveyors

Channel Options

Blow Off Nozzles

Part Unload Baffles

Screen Frame Mounted Air Knife

Separation Options

HR Combo with Inverse Separation

Inverse Separation Screenframe

Magnetic Drum to Belt Separation

Control Panels

Fully-Automatic for Chemical Accelerator Process

Standard Semi-Automatic

Rinse and Prewash

Prewash or Treatment Station for Cob Meal Dryer

Rail Screen with Spray Rinse

Screen Deck Rinse Station – Part Unload Baffles shown on inside wall. Screen is reverse angel hole urethane.

Lift Options

Machine Discharge Lift Station

Flip Gate Options

Inside Channel Load Chute

Middle Screen Frame Flip Gate

Nose Flip Gate

Pneumatic Actuators for Media Gates or Screen Deck Flip Gates

Technical Specifications

| MODEL | Total Capacity L (cu.ft.) | Max Working Capacity L (cu.ft.) | Overall Diameter mm (in.) | Overall Height mm (in.) | Process Channel Width mm (in.) | Center Column Diameter mm (in.) |

|---|---|---|---|---|---|---|

| HR-3 SL CL | 165 (5.5) | 75 (2.5) | 1066 (42) | 1092 (43) | 190 (7.5) | 660 (26) |

| HR-5 SL CL | 300 (10.71) | 150 (5) | 1236 (48.7) | 1181 (46.5) | 259 (10.2) | 660 (26) |

| HR-11 SL CL | 601 (20.4) | 300 (10) | 1555 (61.25) | 1320 (52) | 317 (12.5) | 850 (33.5) |

| HR-17 SPT | 990 (33.1) | 381 (15) | 1178 (70) | 1346 (53) | 381 (15) | 965 (38) |

| HR-17 CPT | 990 (33.1) | 340 (12) | 1178 (70) | 1346 (53) | 381 (15) | 965 (38) |

| HR-23 SPT CPT | 1500 (50.3) | 540 (18) | 1930 (76) | 1346 (53) | 457 (18) | 965 (38) |

| HR-29 SPT CPT | 1699 (60.0) | 2032 (80) | 1619 (63.75) | 508 (20) | 965 (38) | |

| HR-60 SPT | 1472 (52) | 1530 (51) | 2743 (108) | 2032 (80) | 558 (22) | 1549 (61) |

| HR-100 SPT | 6720 (224) | 2460 (82) | 3048 (120) | 2184 (86) | 685 (27) | 1549 (61) |

| MODEL | Screen Deck Width mm (in.) | Screen Deck Height mm (in.) | Base Diameter mm (in.) | Drain Sizes mm (in.) / # of Drains | Motor Horse Power kw (HP) | 460 Volts Amp Load | 230 Volts Amp Load | Aprox Shipping Weight kg (lbs.) |

|---|---|---|---|---|---|---|---|---|

| HR-3 SL CL | 152 (6) | 939 (37) | 1041 (41) | 101.6 (4) / 1 | 2.2 (3) | 7.8 | 12.6 | 997.9 (2,200) |

| HR-5 SL CL | 203 (8) | 873 (39) | 1193 (47) | 101.6 (4) / 3 | 2.2 (3) | 7.8 | 12.6 | 1360.8 (3,000) |

| HR-11 SL CL | 279 (11) | 1066 (42) | 1448 (57) | 101.6 (4) / 3 | 5.6 (7.5) | 14 | 25 | 2267.9 (5,000) |

| HR-17 SPT | 330 (13) | 1016 (40) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2494.7 (5,500) |

| HR-17 CPT | 330 (13) | 1016 (40) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2492.7 (5,500) |

| HR-23 SPT CPT | 381 (15) | 1066 (42) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2812.2 (6,200) |

| HR-29 SPT CPT | 432 (20) | 1245 (49) | 1676 (66) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2993.7 (6,600) |

| HR-60 SPT | 482 (19) | 1473 (58) | 2642 (104) | 101.6 (4) / 3 | 22.3 (30) | 43 | 83 | 5443.1 (12,000) |

| HR-100 SPT | 609 (24) | 1575 (62) | 2642 (104) | 101.6 (4) / 3 | 22.3 (30) | 43 | 83 | 9298.6 (20,500) |

Montfort International

G1P 3T3, Canada