Saw Blade Lube System by UNIST

Cutting Edge MQL Technology for CNC Machines

Unist saw blade lubrication systems deliver all the benefits of Minimum Quantity Lubrication (MQL) to your band or circular saw in a durable, easy-to-install package. Longer lasting blades, better cut quality, fluid savings, and clean, dry chips are just a few of the reasons people love our systems and Coolube® lubricant.

If you’re currently using flood coolant on your saw, switching to a Unist saw blade lubrication system will completely eliminate the need for coolant, alleviating the health and safety concerns it creates as well as the ongoing costs of treatment and disposal.

Advantages of the Saw Blade Lubrication Systems

- Eliminate the mess of flood coolant

- Reduce fluid usage

- Extend blade life

- Dry chips are worth more money

Improved Results: Sawing Inconel with Unist

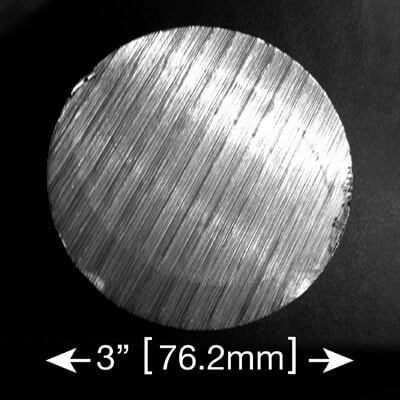

Before

The photo shows cut quality before the Unist system was added. This cut was made using typical flood coolant and resulted in a blade life of approximately 5 days. As you can see, the cut has generated excessive chatter and a large burr on the edge of the stock (click each image for a larger view).

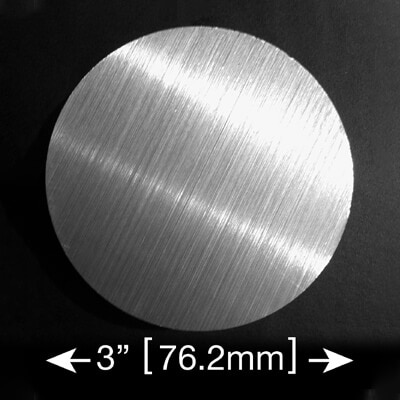

After

The photo shows the same material cut with the same blade after a Unist band saw lubrication system was installed. The cut was made using our Coolube® 2210EP lubricant. Not only was the cut quality greatly improved, but the customer experienced a substantial blade life increase! This customer was able to eliminate the cost and mess associated with flood coolant and also saves considerably on blade costs.

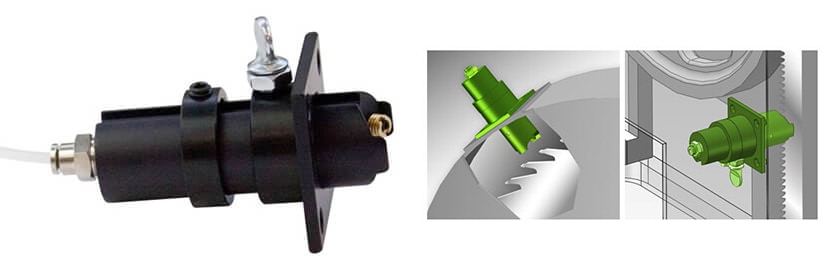

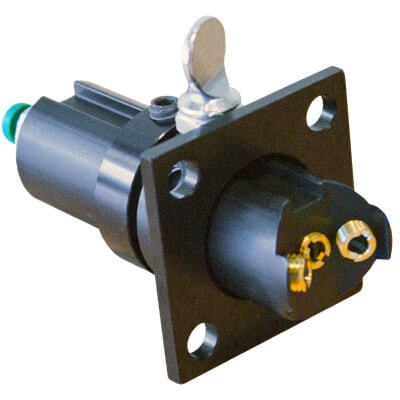

Options de buses

The Bat Nozzle was designed to easily fit on a wide variety of circular saws, vertical band saws, and horizontal band saws. The nozzle includes a 1.75” (45 mm) square mounting flange that can be attached to the blade guard. A 1” (25 mm) diameter hole drilled through the guard allows the nozzle to be centered over the blade. The nozzle position can then be adjusted as close to the blade as required with a thumb screw. Two outlets on the sides of the blade and a third outlet spraying directly into the gullet of the teeth assure superior application of lubricant to the saw blade. The Bat Nozzle is available in various lengths to accommodate a broad range of saws.

The Bat Nozzle was designed to easily fit on a wide variety of circular saws, vertical band saws, and horizontal band saws. The nozzle includes a 1.75” (45 mm) square mounting flange that can be attached to the blade guard. A 1” (25 mm) diameter hole drilled through the guard allows the nozzle to be centered over the blade. The nozzle position can then be adjusted as close to the blade as required with a thumb screw. Two outlets on the sides of the blade and a third outlet spraying directly into the gullet of the teeth assure superior application of lubricant to the saw blade. The Bat Nozzle is available in various lengths to accommodate a broad range of saws.

Ideal for:

- Circular saw: Blade 20” [508 mm] or under

- Horizontal band saw: All blade sizes

- Vertical band saw: All blade sizes

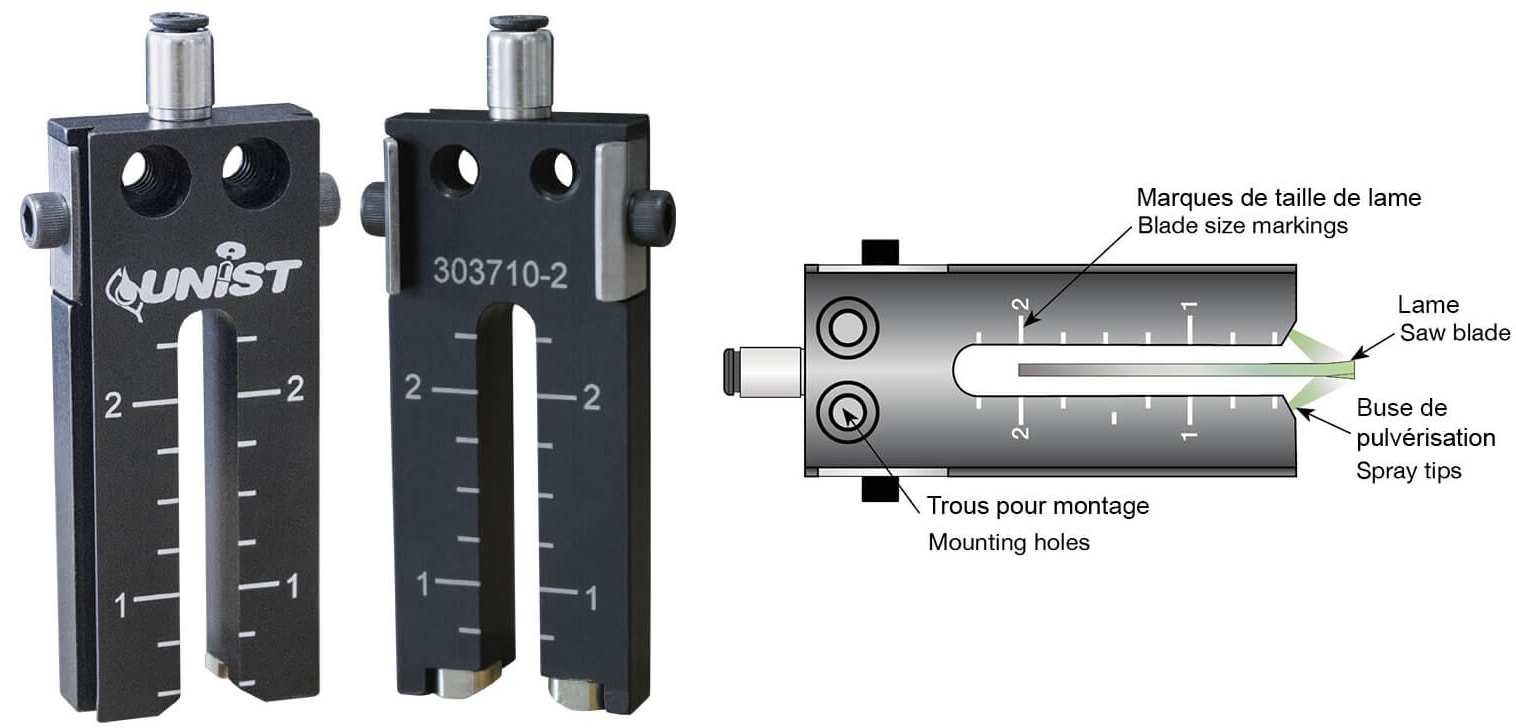

When blade guide lubrication is required, the Band Saw Guide (BSG) Nozzle will lubricate the sides of the blade to help minimize friction. The BSG Nozzle can be mounted directly to a guide block, to the BSB Nozzle, or installed with the mounting kit. When paired with a BSB Nozzle, this will provide lubrication for both the cutting edge and the sides of the blade.

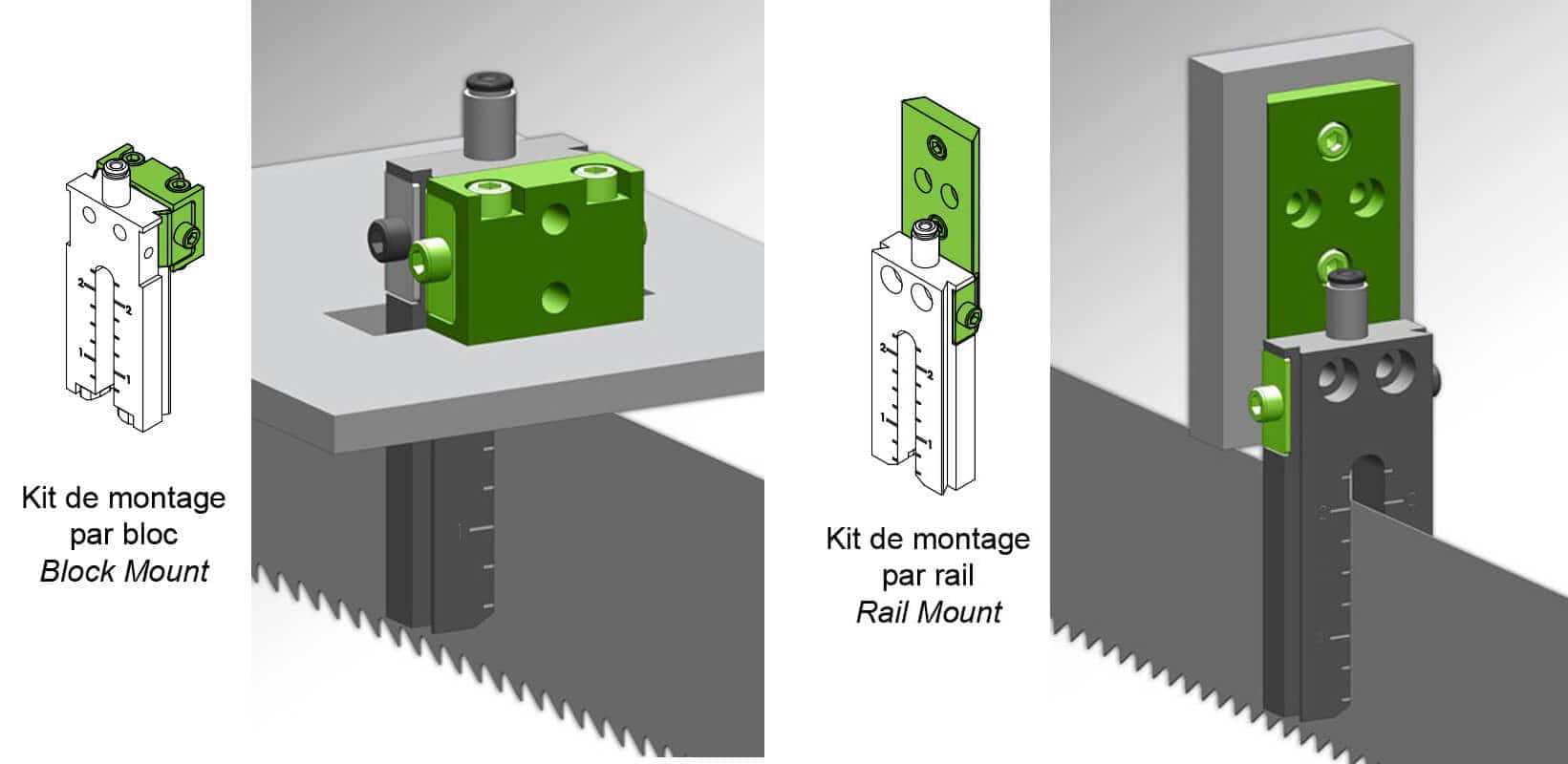

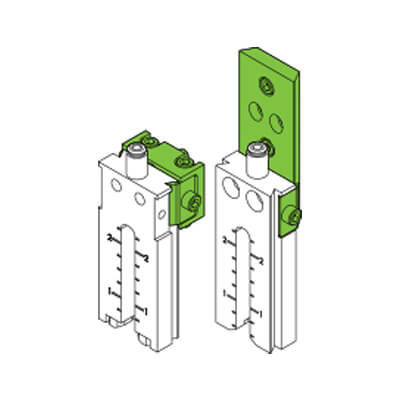

Mounting Kit

For maximum mounting flexibility, two mounting brackets are available for the band saw nozzles. The block mount allows either a blade or the guide nozzle to be held 90 degrees from the mounting surface. The rail mount allows the vertical height of the BSB or BSG Nozzles to be easily adjusted by sliding the nozzle up or down and tightening the clamp at the side.

Technical Specifications

| Outputs: | Continuous Output – Pulse Generator = infinite cycling at an adjustable 5-200 pulse/min. Multiple outputs - up to 3 pumps for 3 individual output options |

| Pumps(4 types available): | Standard 1 Drop (0.03 mL per stroke) Standard 3 Drop (0.10 mL per stroke) Multi-Viscosity(MV) 1 Drop (0.045 mL per stroke) Multi-Viscosity(MV) 2 Drop (0.10 mL per stroke) |

| Actuation: | Control air input with manual valve, air pilot valve, or 3-way solenoid valve (110VAC or 24VDC) |

| Reservoirs: | <16 oz. (473 ml), polyethylene 32 oz. (946 ml), polyethylene 64 oz. (1893 ml), polyethylene 64 oz. (1893 ml), polyethylene with low level |

Options & Accessories

Actuation - Air pilot valve

For use with a low-flow air signal.

Actuation - Solenoid valve

For actuation using an electrical signal from the machine.

Actuation - Manual valve

3-way slide valve for simple manual on/off control.

Actuation - Foot valve

Hands-free manual operation.

Pump - Standard 1-drop pump

(0.03 mL per stroke)

Pump - Standard 3-drop pump

(0.10 mL per stroke)

Pump - Multi-Viscosity 1-drop pump

(0.045 mL per stroke) Select this option to match your fluid delivery needs

Pump - Multi-Viscosity 2-drop pump

(0.10 mL per stroke) Select this option to match your fluid delivery needs

Multiple outputs - 1-3 outlet enclosure

1-3 outlet enclosure

Reservoirs - 16 oz [473 mL]

Polyethylene

Reservoirs - 32 oz [946 mL]

Polyethylene

Reservoirs - 64 oz [1893 mL]

Polyethylene with low level switch (Also available without a low level switch)

Output type - BAT nozzle

The Bat Nozzle fits on a wide variety of circular saws, vertical band saws, and horizontal band saws.

Output type - Band Saw Blade Nozzle

The Band Saw Blade Nozzle provides alternative mounting options and delivers ideal spray pattern for horizontal band saws

Output type - Band Saw Guide Nozzle

The Band Saw Guide Nozzle lubricates the sides of the blade to minimize friction when blade guide lubrication is required.

Mounting - Band Saw Nozzle Mounting Kit

For maximum flexibility, every Band Saw Nozzle Mounting Kit includes two mounting brackets. The block mount allows either a blade or the guide nozzle to be held 90 degrees from the mounting surface. The rail mount allows the vertical height of the BSB or BSG Nozzles to be easily adjusted by sliding the nozzle up or down and tightening the clamp at the side.

Montfort International

G1P 3T3, Canada