Print this page

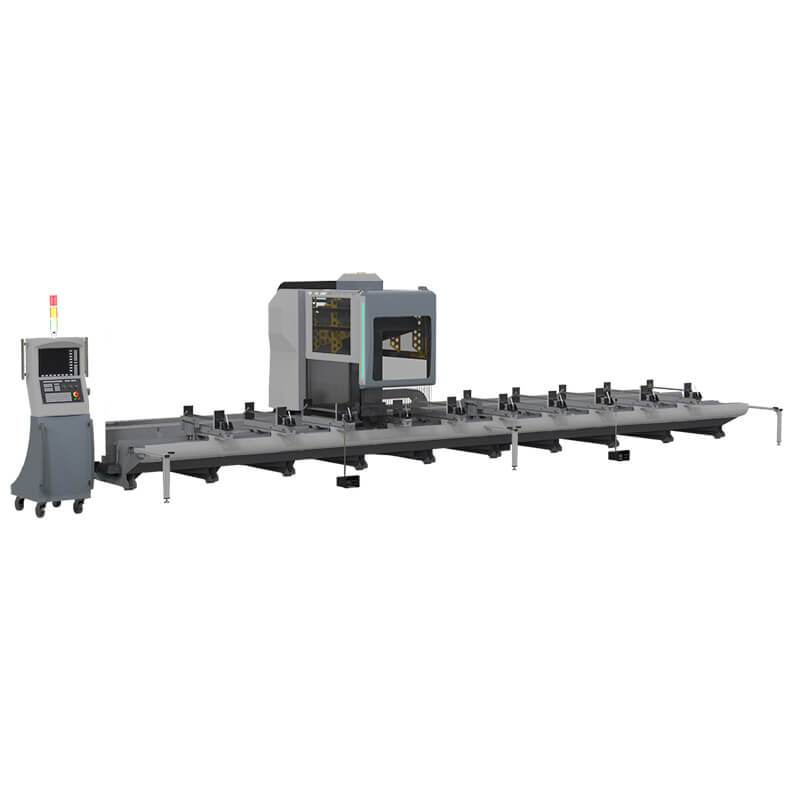

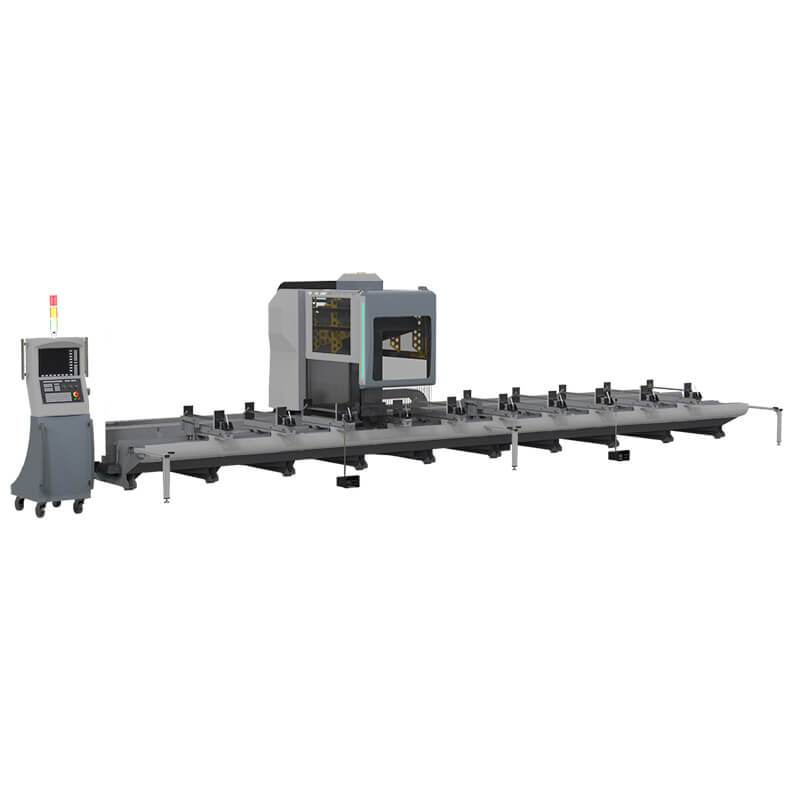

LESTHER J-CNC S5 - 5 Axes CNC Machining Center

5 axes CNC machining center specially designed for aluminum material, POM, light alloy cutting, drilling, slotting, machining. Any surface or plane in 3D space can be processed. 5 axis can rotate into any angle and direction. Equipped with two-layer tool magazines for storing sawblade and cutting tools on both upper and lower magazine,featuring fast tool change.

5-Axes Machining Center

- Any surface or plane in 3D space can be processed.

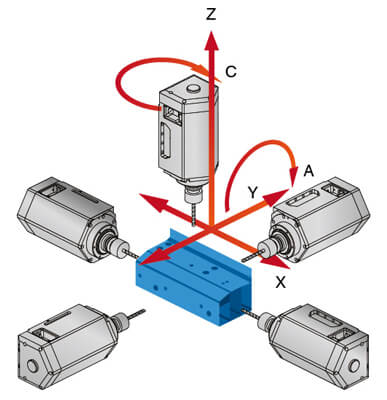

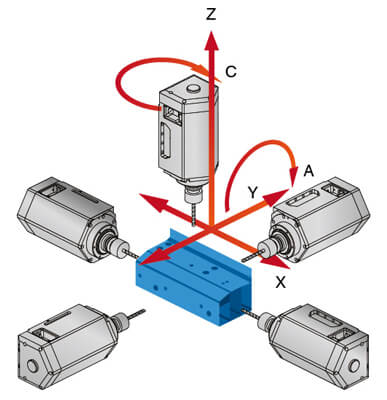

- 5 axis can rotate into any angle and direction.

- Even machining irregular profile ,5 axis can keep specific angle to the surface.

- Specifically for aluminum material, POM, light alloy cutting, drilling, slotting, machining.

- Syntec 5 axis controller, with 5 axis head which imported from Italy, can make the five-sided machining once.

- Tempering treatment heavy base keep strong and accuracy.

- German CAM software and vise automatic positioning function, make the 5 axis machining process more simplify.

- The angular head can be tilting A-Axis : ±120˚, Spindle rotary C-Axis : ±120˚, Spindle rotary C-Axis : ±220˚, making it suitable for angular drilling and tapping operations. Suitable for face milling and multi-surface machining in one setup.

- Tilting degree through computer control.

- Angle Indexing accuracy

- A tool clamp / release button is provided on the angular head.

- Integrated type spindle features high accuracy, low vibration, low noise and no backlash

5 AXIS Schematic diagram

Machine Features

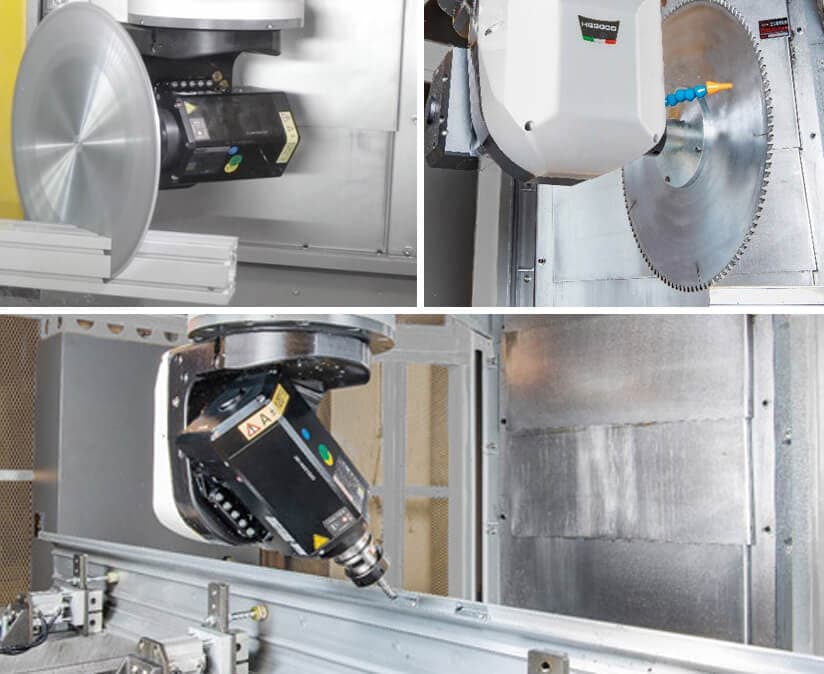

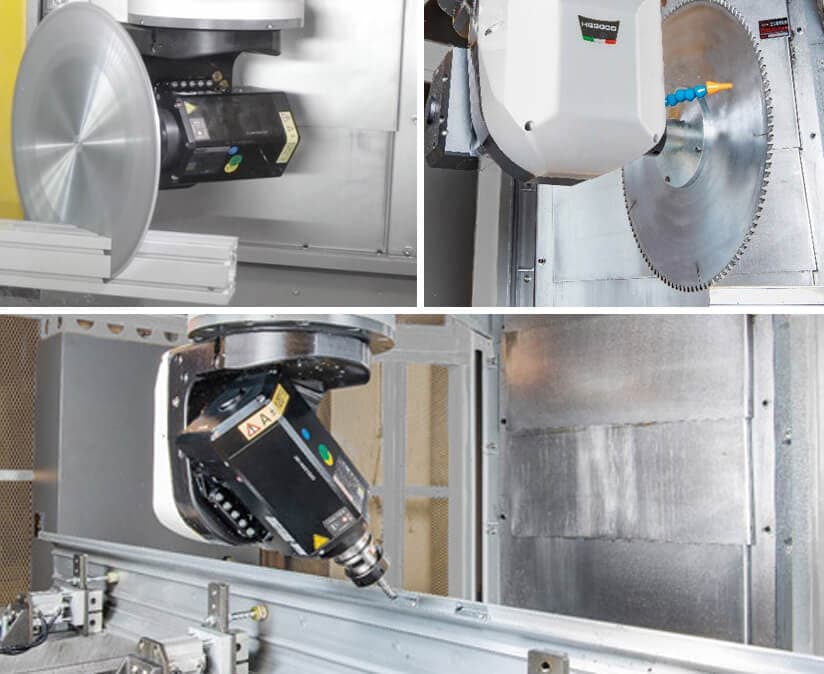

Equipped with two-layer tool magazines for storing sawblade and cutting tools on both upper and lower magazine,featuring fast tool change.

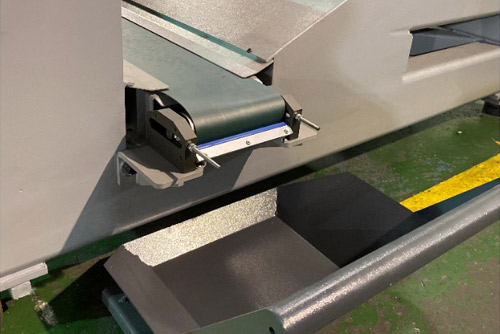

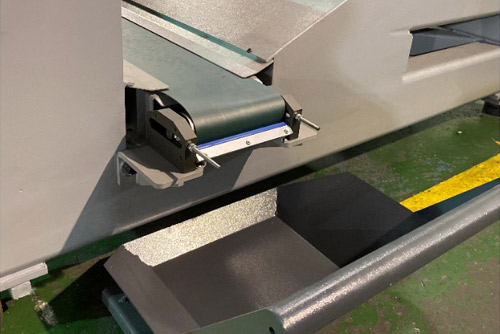

Specially designed clamping for irregular workpieces to keep the clamping stable. The clamp is equipped with roller to avoid workpiece damage.

Automatic clamp moving and positioning system combined with automatic clamp position sensing function effectively prevents the crash from spindle hitting the vise.

Applicable Materials

- Aluminum

- Other non-ferrous metals

Applicable Industries

- Public transportation , aluminum , light alloy profile processing.

- Aerospace industry.

- long-shaped aluminum profiles.

- Square tube profile cutting, drilling, slot milling.

- Aluminum doors and Windows industry

- Curtain wall(glass wall)

- Extruded aluminum

- Long material parts

Safety cover (opt.)

Chip Conveyor (opt.)

Technical Specifications

| MODEL | J-CNC S5 (5 Axis) |

|---|---|

| X Axis Stroke | 3,500 mm / 4,500 mm / 5,500 mm / 6,500 mm (Opt.) |

| Y Axis Stroke | 400 mm (5 axes) (3 axes: 700 mm) |

| Z Axis Stroke | 800 mm (saw blade processing stroke 350 mm) |

| A Axis Swivelling Angle | ±120° |

| C Axis Swivelling Angle | ±220° |

| Table Type | Vise |

| Table Size | 400 X 3,500 ~ 6,500 mm |

| Table Height From Floor | 680 mm |

| Spindle Speed | 20,000 R.P.M. |

| Spindle Motor | 10 HP (7.5 kw) |

| Spindle Taper Cone | HSK 63F |

| Sawblade size | 16" X 1" bore |

| Rapid Feed Rate (X / Y / Z) | X : 50 m/min, (Opt. 70 m/min) Y : 24 m/min, Z : 24 m/min A:75°/S, C : 75°/S |

| Servo Motors of 3 Axis | X:2.9 kw , Y : 850w, Z : 1.8 kw, A : 750w, C: 750w |

| Cutting Feed Rate | F : 1 ~ 5,000 mm/min |

| Repeatability Accuracy | X : ±0.02 mm Y : ±0.01 mm Z : ±0.01 mm |

| Magazine Capacity | 12 Tools |

| Tool Holder | HSK 63F |

| Required Pneumatic Pressure | 6 kgs/cm2 |

| Machine Dimensions(L x W x H) | 8,000 ~ 11,000 x 3,150 x 3,900 mm |

| Packing Dimensions(L x W x H) | 8,100 ~ 11,100 x 2,300 x 2,450 mm |

| Machine Weight | 4,500 ~ 6,500 kgs |

Montfort International

2500 av. Watt, Quebec City (Qc),

G1P 3T3, Canada

G1P 3T3, Canada

1-800-463-6668

info@montfort-international.com