Print this page

LESTHER J-CNC18MDS Milling, Drilling, Tapping and Sawing Composite Machine

CNC milling, drilling, tapping and aawing composite machine with 8 tools tool magazine. Best choice for aluminum, light alloys and PVC. According to process situation, separately choose sawing, drilling, milling and tapping at program. Provide 3 kinds of mode for processing: cut mode, long part mode, mill and cut mode

Machine Features

- To complete all step of machining in one machine 18MDS that is the best choice for aluminum, light alloys and PVC.

- Complete with strong pusher system for clamping and feeding in the operating unit.

- Performance high speed and high accuracy machining.

- With auto tool change we could have more options for processing and also 18MDS is available to add an angular head for special working.

- Automatic sawing, milling, drilling and tapping multi-function at one High pression high speed spindle for drilling, tapping and milling.

- CNC control with easy operation by touch screen based with SYNTEC system.

- According to process situation, separately choose sawing, drilling, milling and tapping at program.

- 18MDS provide 3 kinds of mode for processing:

- CUT MODE

- LONG PART MODE

- MILL AND CUT MODE

- 8 tools tool magazine for more convience.

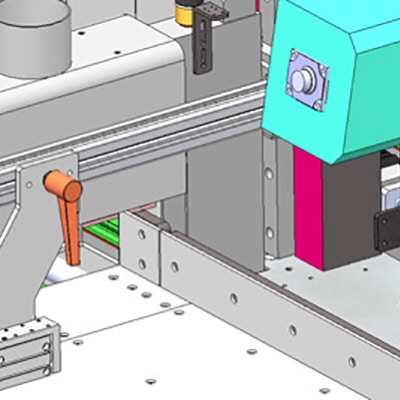

- Schematic diagram

Applicable Materials

- Aluminum

- Plastic

- Other non-ferrous metals

Applicable Industries

- Public transportation , aluminum , light alloy profile processing.

- Aerospace industry

- long-shaped aluminum profiles

- Square tube profile cutting, drilling, slot milling.

- Aluminum doors and Windows industry

- Curtain wall(glass wall)

- Extruded aluminum

Standard Equipment : Clamping

Optional Equipment

Angular Head

Optional: 90 ° angular head with sawblade.

Tool Magazine

Optional tool magazine for optional tool change automatically.

Measuring System

Optional: Auto measuring system

Technical Specifications

| Model | J-CNC 18 MDS |

|---|---|

| Applicable Machine | J-455 |

| Tool Magazine Capacity | 8 pcs |

| Automatic Drive System | Ball screw (Servo motor drive) |

| Cutting Capacity (H x W) | 120 x 120 , 100 x 200 , 20 x 280 mm |

| Cutting Length Display Set Up | Touch-sensing screen |

| Hydraulic feed motor | 1 HP |

| Stroke | 1.25 M |

| Touch-sensing screen | 12” |

| Saw blade size | 18” x 1” bore |

| Air pressure | 6 kgs / cm2 |

| X-Axis Stroke | 1,100 mm |

| Y-Axis Stroke | 325 mm |

| Z-Axis Stroke | 330 mm |

| X1 Servomotor | 850 W |

| X2 Servomotor | 850 W |

| Y-Axis Servomotor | 750 W |

| Z-Axis Servomotor | 750 W |

| Spindle Speed | 12,000 R.P.M. |

| Spindle Taper | NBT30 |

| Spindle Motor | 3.8 kw |

| Saw Motor | 7.5 HP |

| CNC Controller | SYNTEC |

| Rapid feed rate (X / Y / Z) | X:40 M/min ; Y:25 M/min ; Z:25 M/min |

| Machine Dimensions(L x W x H) | 3,500 x 2,120 x 2,650 mm |

| Packing Dimensions (L x M x H) | 3,600 x 2,220 x 2,750 mm |

| Net / Gross Weight | 2,600 / 2,780 kgs |

Montfort International

2500 av. Watt, Quebec City (Qc),

G1P 3T3, Canada

G1P 3T3, Canada

1-800-463-6668

info@montfort-international.com