LESTHER J-CNC H - 3 Axes Machining Center

J-CNC6500 H Type Extra Fine Craftsmanship The Ultimate in Performance Designed for Long and Short Work piece Machining

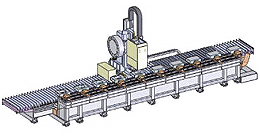

Long-scale processing

Short-scale multiple processing

Multiple area processing

4th axis processing (Opt.)

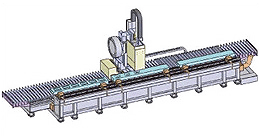

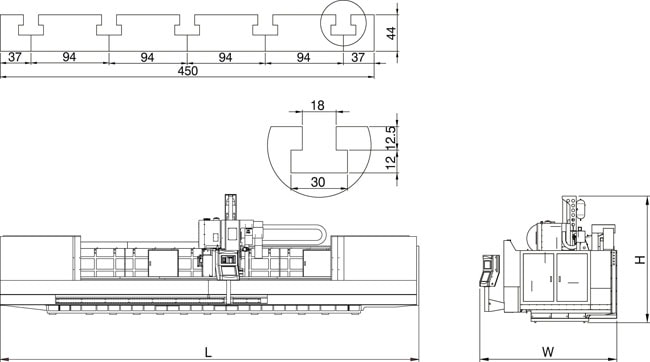

3 AXIS Schematic Diagram

Machine Features

- The base is fabricated from heavy gauge steel plates and scientifically reinforced, allowing for solid support for the column and work pieces.

- Travelling column design features increased machining efficiency and accuracy.

- The oversized box-type column is manufactured from high quality cast iron.

- Large diameter ball screw on x-axis is firmly supported to eliminate self-deflection problems.

- 3 axis adopt 45 mm P class high precision linear guide ways; X axis features 8 blocks, Y and Z axis are 6 blocks.

- Automatic lubricator delivers lubrication oil to all linear ways and ball screws.

- 3 axis ball screws are direct coupled with drive motors, featuring no backlash, high transmission efficiency and high accuracy.

Applicable Materials

- Aluminum

- Steel

- Cast iron

- Mould

- Other non-ferrous metals

Applicable Industries

- Aluminum door and windows

- Curtain wall (glass wall)

- Train rail

- Steel knife

- The body of machine

- The machine is designed with a travelling column and a fixed table.

- With the travelling column configuration,work piece weight will not affect the transmission system. As a result,consistent machining accuracy can be achieved.

- Each linear way on the Y-axis is fitted with 3 sliding blocks to assure ultra-high stability when the Y-axis is moving.

| Modèle | J-6500H | J-5500H | J-4500H | J-3500H |

|---|---|---|---|---|

| Dimensions de la machine (L x W x H) | 12,000x3,100x3,100mm | 11,000x3,100x3,100mm | 10,000X3,100X3,100mm | 9,000x3,100x3,100mm |

| T-Slot | 6,500x450mm | 5,500x450mm | 4,500X450mm | 3,500x450mm |

Machining Way

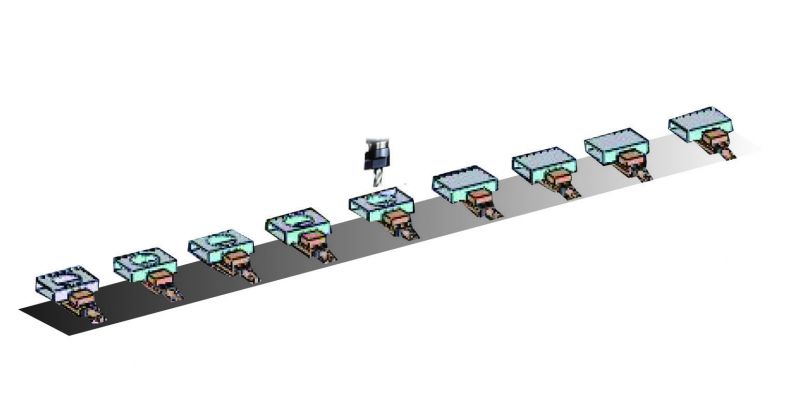

Multi-Machining for Short Work Pieces

For machining short work pieces, the operator may mount the work pieces on the table to machine simultaneously.

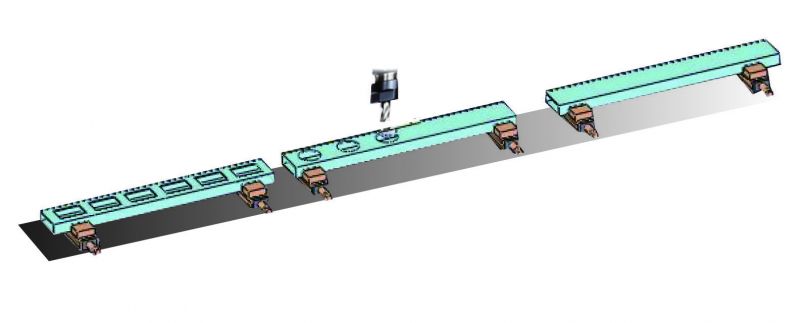

Extra Long Work Piece Machining

This machine is excellent for machining extra-long work pieces with only one setup. Suitable machining includes milling, drilling and tapping. With such machining nodes, you can save considerable time.

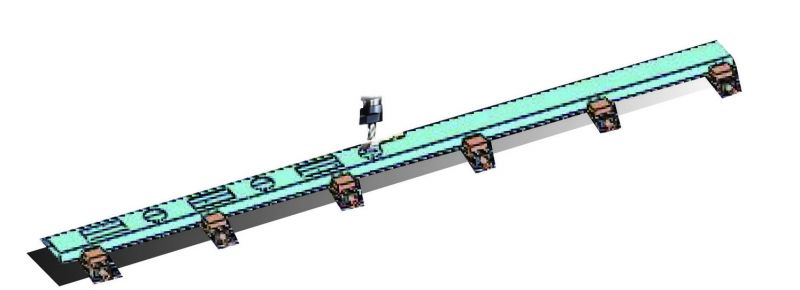

Different Parts Machining

With this mode of machining, greater efficiency can be obtained.

Standard Equipment

PC-Based CNC Control

The machine is equipped with a PC-based CNC control as standard equipment. It is easy to learn and operate. Upon request Mitsubishi / Fanuc or Siemens CNC control is available (optional).

Arm Type Magazine

The ARM type magazine rotation is driven by a cylindrical cam for fast and dependable is 24 tools. Random tool selection provides highly efficient tool changing.

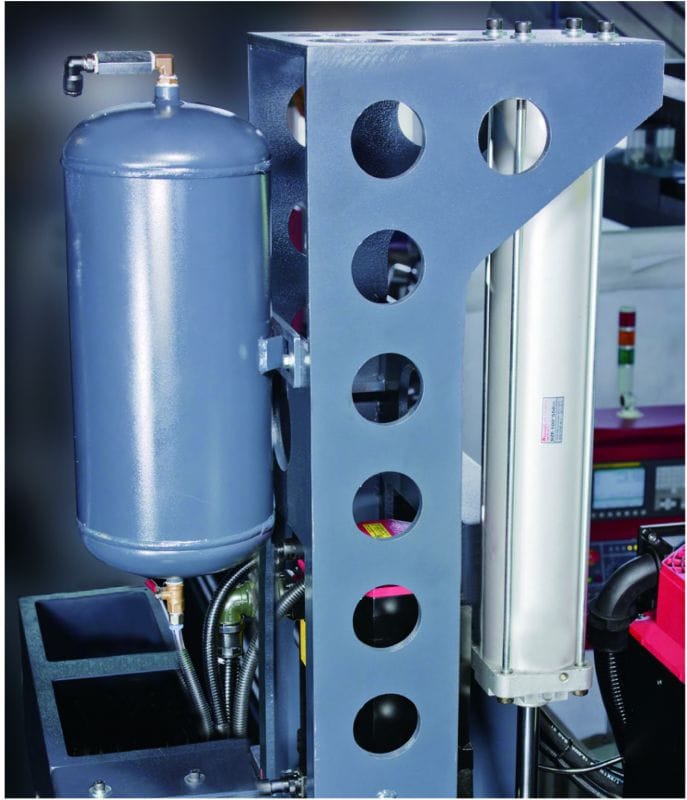

Pneumatic Balance On Z-AXIS

The Z-axis movement is balanced by an air cylinder, allow the Z-axis to move more smoothly. The pneumatic balance system is equipped with and accumulator to supply stable air flow at all times.

Oil Mist Cooling

The machine is equipped with an oil mist cooling system for efficient cooling of cutting tool and work piece. It not only extends the service life of the tool, but also ensures superior cutting quality.

Laser Interferometer

After each machine has been assembled, our experienced personnel applies a Laser interferometer to inspect and calibrate ball screw pitch error and backlash, positioning accuracy, as well as repeatability on the X, Y and Z-axes. Through the laser inspection process, we can guarantee high feed accuracy on three axes as well as overall machining accuracy.

Ball Bar Test

To assure the highest structural mechanical assembly accuracy, and to eliminate the reverse spike phenomenon, all Bar tested during the assembly processes. The test will calibrate the machine to the optimum status, thus extend the life time of axial ball screw and slide ways.

Spindle Cooler

Heat Exchanger for Electrical Cabinet

Chain Type Chip Conveyor

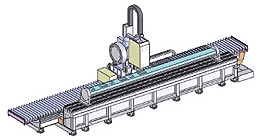

5 Groove T-slots Table

Advanced CNC Controller

SYNTEC controller

Mitsubishi controller

Fanuc controller

Optional Equipment

Imported High Precision Gear Reducer

The X-axis movement is driven by a servo motor and transmitted through high precision ball screw with gear reducer. This special design not only produces powerful driving force, but also provides high positioning accuracy on the X-axis.

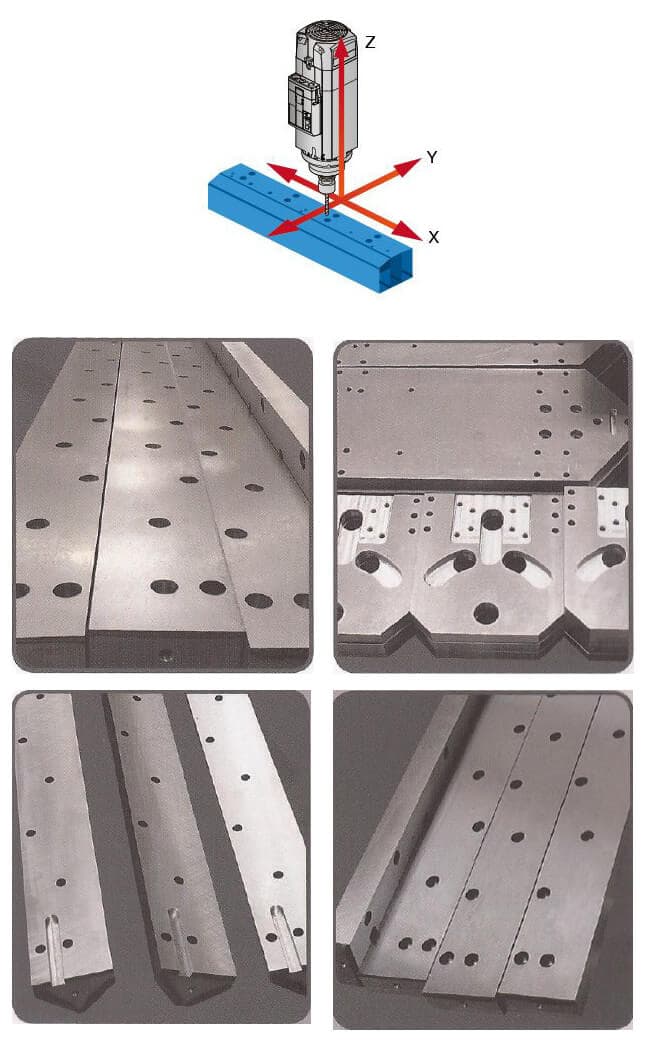

Ball Screw Support

The X-axis is transmitted through a ø80 mm extra-large ball screw, which is supported by two blocks to improve self-deflection of the screw. This help upgrade positioning accuracy on the X-axis.

Belt-Drive Spindle (BT-50 8,000 R.P.M.)

Gear Box Type Spindle

Planetary Gear Reducer

Screw Type Chip Conveyor

Hydraulic Vise

Pneumatic Vise

Reference Stopper

Angle Head (90 degrees or 0-120 degrees)

Workpiece Measuring

Controller(SIEMENS)

Technical Specifications

| Model | J-CNC6500H |

|---|---|

| X-Axis Stroke | 6,500 mm (Opt.3,500 mm / 4,500 mm / 5,500 mm) |

| Y-Axis Stroke | 510 mm (Opt.650 mm) |

| Z-Axis Stroke | 510 mm (Opt. 700 mm) |

| Distance From Spindle Nose To Table Surface | Min. 160 mm, Max. 670 mm |

| Table Type | 5 Groove T-slots Table |

| Table Size | 450 x 6,500 mm (Opt. 600 x 6500,For Y-Axis stroke 650 mm) |

| Max. Load | 1,000 kg |

| T-Slots(No. x W x P) | 5 x 94 x 450 mm |

| Spindle Speed | 12,000 |

| Spindle Motor | 15 HP (11 kw) |

| Spindle Taper Cone | BT40 (Opt. BT50 / 8,000 R.P.M.) |

| Rapid Feed Rate(X / Y / Z) | Gear rack X:40 m/min / (Opt. Ball screw X:24 m/min) Ball screw Y:24 m/min, Ball screw Z:24 m/min |

| Servo Motors of 3 Axes | X:5 kw, Y:3.5 kw, Z:3.5 kw |

| Cutting-Feed Rate | F : 1 ~ 5,000 mm/min |

| Repeatability Accuracy | X: ± 0.02 mm, Y: ± 0.01 mm, Z:± 0.01 mm |

| ATC Magazine Capacity | 24 Tools |

| ATC Type | Arm-type |

| ATC Tool Holder | BT40 |

| ATC Pull Stud | 45° |

| ATC Max. Tool Length | 300 mm |

| ATC Max. Tool Diameter | 80 mm |

| ATC Max. Tool Weight | 7 kg |

| Required Pneumatic Pressure | 6 kg/cm2 |

| Machine Dimensions (L x W x H) | 15,000 x 3,200 x 3,000 mm |

| Packing Dimensions(L x W x H) | 11,800 x 2,300 x 2,500 mm (2 40-inch containers) |

| Machine Weight | 15,000 - 21,000 kgs |

Montfort International

G1P 3T3, Canada