Print this page

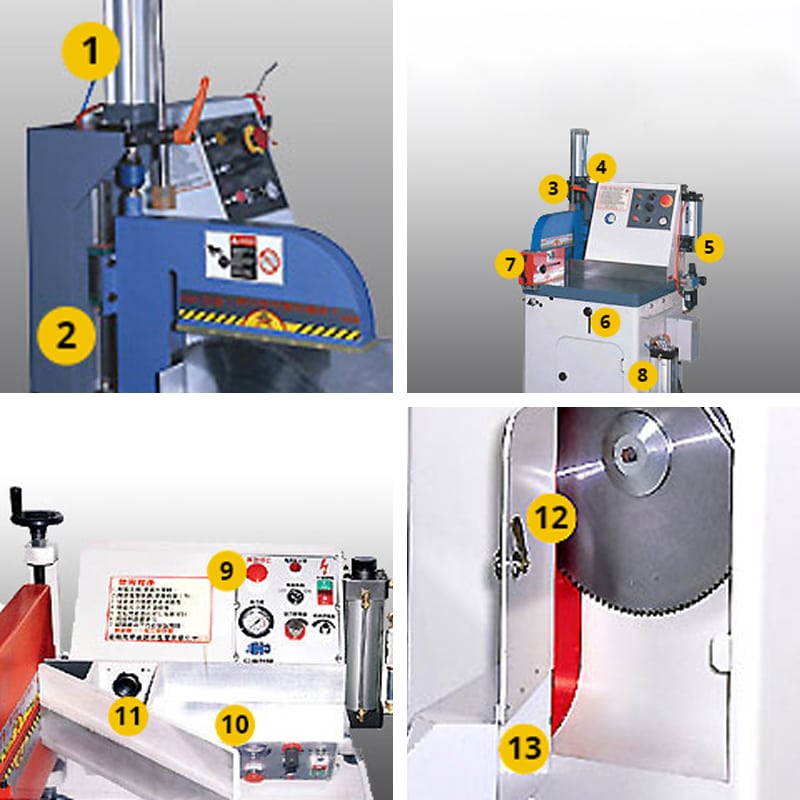

LESTHER J-18 D Single Head Cutting Machine

The Lesther J-18 D is a single head cutting machine for aluminium which allows 90° cut-off or 45° cutting with the use of a fixture (Optional).

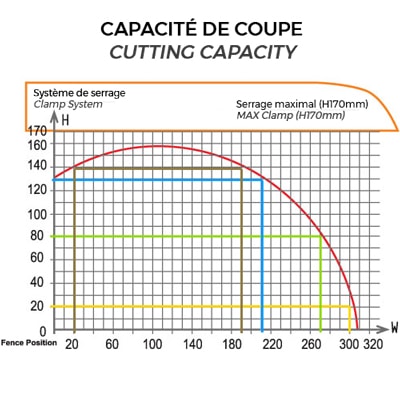

Features

- Simply step on the footswitch and the machine will safely and easily perform automatic clamping, automatic oil spraying and automatic cutting of the workpiece.

- The hidden saw blade cuts from bottom to top. You can cut a single workpiece or multiple workpieces simultaneously.

- Automatic oil mist spray during cutting provides cooling and lubrication effect.

- CThe cutting feed is driven by a hydro-pneumatic cylinder for a very stable cutting speed.

- The coating inside the machine is baked at a high temperature of 200 degrees (powder coating), and the coating does not peel off and is resistant to bumping.

- The machine can perform 90° cutoff or 45° cut using fixtures (optional).

- Workpiece clamping pressure can be adjusted.

- The independent hydro-pneumatic cylinder clamp makes the machine suitable for cutting solid materials and industrial aluminum extrusion.

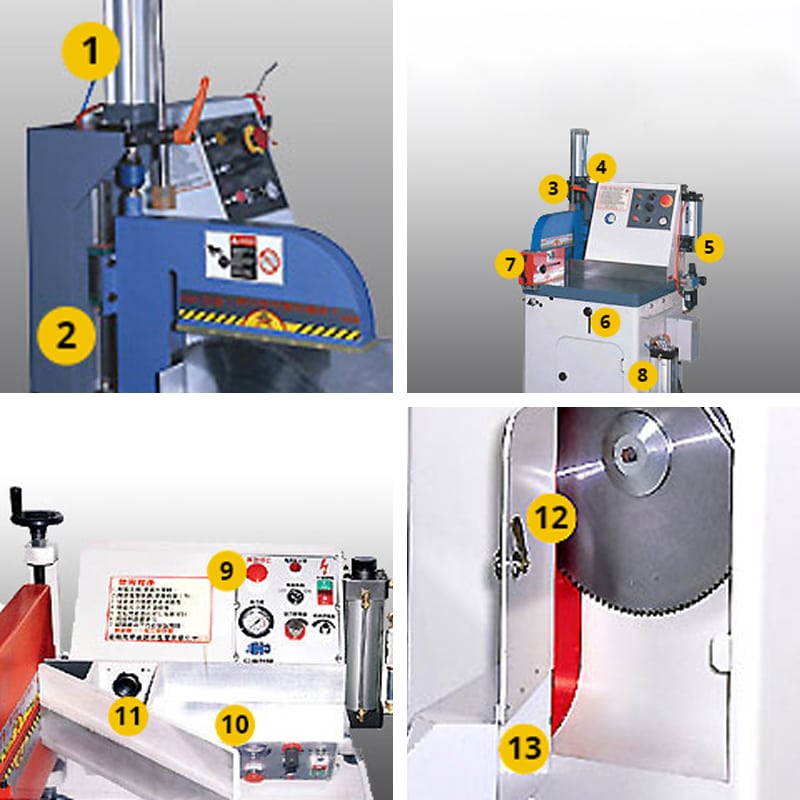

Vacuum Oil Mist Unit

The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for splashing. It provides lubrication and cooling functions, ensuring no dust deposit and saw blade, high cutting accuracy and long service life of saw blade.

Saw Blade Spindle

The saw blade spindle is heat treated and plated for greatly increasing the spindle life.

Description

- The clamping system is controlled by an independent air cylinder.

- The clamping system moves on linear guide way, that assures stable clamping.

Features:

* The clamping speed and cutting speed can be adjusted separately according to the material type, so as to achieve a more stable sawing effect (fast and stable sawing material), and the clamping system can clamp the material completely and tightly.

* The clamping pressure can be adjusted separately according to the material type to prevent material damage caused by over-pressure. - Adjustable clamping height.

- Adjustable clamping speed.

- Adjustable cutting speed.

- Adjustable cutting height.

* The operator may adjust clamping height and speed and cutting height and speed according to work piece size and thickness for saving waiting time. - Push-pull type safety guard.

- Accurately controlled oil mist system. greatly improves lubrication and cooling effect, while reducing trouble to a minimum.

- The use of control panel combined with operation sequence label and instruction labels increase operational convenience.

- Table: The specially designed table is precision ground and hard chrome plated to avoidscatching on the table surface. No rusting in 10 years of operation.

- The one-piece fabricated aluminum alloy fence permits 45° cutting If features light weight and can be easily mounted on the machine.

- The convenient door for saw blade replacing. Open the side door to replace the blade. The door can load the whole blade and there won't be any inconvenience for the blade installation as those A typed machine

- Chip Outlet Port. The chips are exhausted through this outlet port. It eliminates inconvenient cleaning for those chip deposited in the machine.

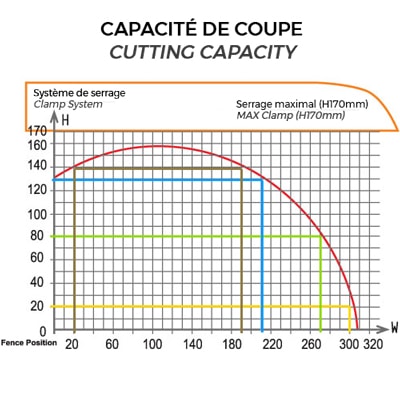

Cutting Capacity

Optional Equipment

- CE Standard

- Infeed, Outfeed Conveyor

- Chip Collector

- Horizontal Clamp

- Hydraulic Feeding

- 45° Fixture

- With Auto3000 for Automatic Positioning, Automatic Feeding(Pusher),Automatic Cutting functions.

Applicable Materials

- Aluminium

- Brass

- Heat sink

- PVC

- Plastic steel

- Bakelite

- Acrylic plastic

- Teflon

- Honeycomb board

- Wood

- Non-ferrous metals

Technical Specifications

| Model | Lesther J-18D |

|---|---|

| Cutting Angle | 90 ° or 45 ° |

| Saw Blade Size | 18" x 1"bore |

| Cutting Capacity(H x W) | 125 x 125, 100 x 230, 60 x 270, 20 x 300 mm |

| Saw Speed | 3,200 R.P.M. |

| Saw Motor | 7 1/2HP(10HP opt.) |

| Pression d'air | 4-6 kgs/cm² |

| Table Area(L x W) | 640 x 380 mm |

| Table Height From Floor | 860 mm |

| Conveyor Length (Opt.) | 1-7 M |

| Poids net | 360 / 440 kgs |

| Machine Dimensions (L x W x H) | 840 x 870 x 1,660 mm |

| Packing Dimensions (L x W x H) | 960 x 990 x 1,860 mm |

Montfort International

2500 av. Watt, Quebec City (Qc),

G1P 3T3, Canada

G1P 3T3, Canada

1-800-463-6668

info@montfort-international.com