| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 1,5 ( 2,0 ) | kW ( hp ) |

| Motor speed | 1400 | tr/min |

| Acoustic emission | 70 | dB |

| Overall dimension (Width x Depth x Height) | 1000 x 1300 x H. 1600 ÷ 1800 | mm |

| Weight standard machine | 750 | kg |

| Feeding speed of workpiece | 1,8 | m/min |

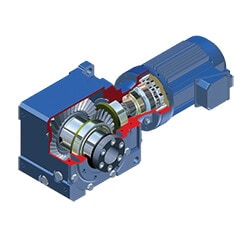

| Gearmotor power | 2400 | N*m |

| Bevel dimension (diagonal) | 0 ÷ 30 | mm |

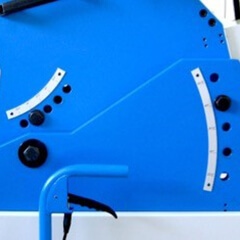

| Bevel angle | 22,5 - 30 - 37,5 - 45 -52,5 | ° |

| Workpiece thickness allowed | 8 ÷ 60 | mm |

| Workpiece diameter allowed | 220 | mm |

| Milling cutter diameter | 160 | mm |

| Workpiece width allowed | 160 | mm |

| Workpiece length allowed | 400 | mm |

Low voltage with padlockable main switch and emergency stop button with electronic motor braking for a quick stop of the machine.

Electronic reversing of the direction of travel for partial sheet metal chamfering.

It mounts on a sturdy structure a powerful and resistant gearmotor designed to absorb and minimize the strong stresses subjected during the life of the machine.

22.5 ° - 30 ° - 37.5 ° - 45 ° - 55.5 ° at any time without the need for any accessories. Graduated vernier for head adjustment, horizontal rearrangement of the machine and sheet thickness.

The miller is specially designed with a toothed edge, such that it is suitable for automatic advancement. The miller is suitable for iron and stainless steel.

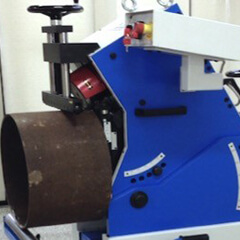

With a simple passage with the supplied accessory, the machine is capable of chamfering round pipes, having a minimum diameter of 180 mm; making grooves at the top of the tube.

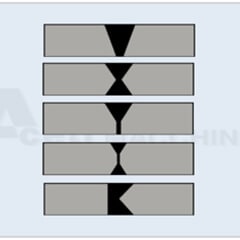

The forms of possible joints are:V; X; Y; double Y and K.

The sheet can be placed on trestles with heights ranging from 970 mm to 1350 mm.Equipped with pivoting wheels that make it easy to move, it is particularly suitable for large sheet metal sheets, avoiding the use of lifting systems.The trolley is equipped with a pneumatic pedal piston and a manual lever for height adjustment.The trolley wheels are complete with brake kit.