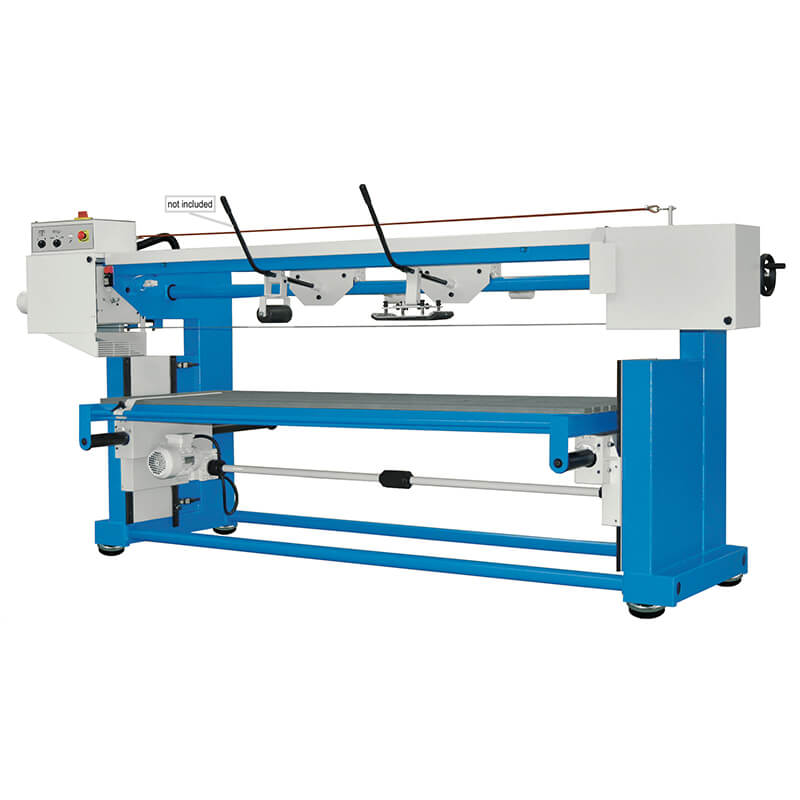

The pad polishing machine allows to carry out finishing and satin finishing operations on flat surfaces such as plates and sheets, bars and tubulars with square or rectangular section, and above all of large dimensions such as carters, boxes, fairings. In addition to sanding, satin finishing and finishing in general, it is possible to carry out grinding and deburring operations on shear cut parts or with thermal cutting such as oxy-fuel and laser cutting. It is also possible to carry out deburring to remove weld seams on molded boxes and fairings.

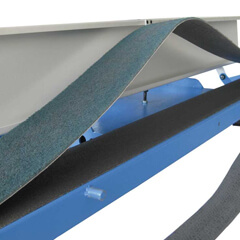

Belts of any type of abrasive grain (corundum, zirconium, ceramic, diamond, agglomerate, cork, Trizact, Scotch-Brite etc. etc.) can be mounted to obtain different finishing qualities.

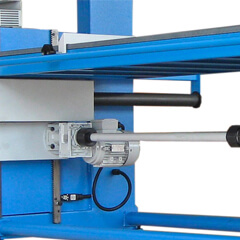

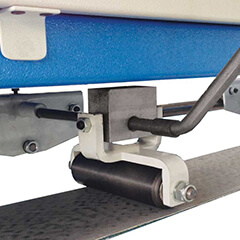

The processing of the details takes place by means of an abrasive belt and a pad that is moved manually by the operator.

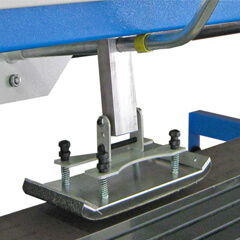

The parts to be machined are positioned on the support table which is covered with fireproof material and is electrically motorized to adjust the height according to the thickness of the parts.

The machine can be equipped with various options in addition to all the various ones.

| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

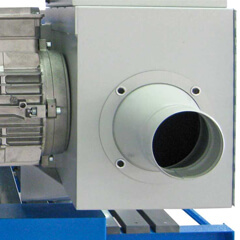

| Motor power | 4,5 ( 6 ) | kW ( hp ) |

| Motor speed | 700 - 1400 | tr/min |

| Acoustic emission | 85 | dB |

| Overall dimension (Width x Depth x Height) | 3700 x 2150 x H. 1600 | mm |

| Weight standard machine | 630 | kg |

| Quantity of abrasive belt | 1 | No. |

| Abrasive belt dimension (wide x length) | 150 x 7000 | mm |

| Peripheral speed | 11 - 22 | m/sec |

| Workpiece thickness allowed | min. 1 ÷ max. 420 | mm |

| Workpiece length allowed | max. 2400 | mm |

| Workpiece width allowed | max. 800 | mm |

| Workpiece weight allowed | max. 150 | kg |