The polishing machine ART.76 allows finishing and satin-finishing work on parts with flat surfaces such as plates and sheets, bars and tubulars with a square or rectangular section.

The processing takes place by means of an abrasive belt, which adjusted according to the thickness of the part, grinds a face for each single pass, combined with a conveyor belt that carries out the automatic advancement of the parts.

In addition to grinding, satin finishing and finishing in general, it is possible with the sole replacement of the abrasive belt, to carry out grinding and deburring work on parts sheared sheets or cutted with thermal cutting such as oxy-fuel and laser.

Belts of any type of abrasive grain (corundum, zirconium, ceramic, diamond, agglomerate, cork, Trizact, Scotch-Brite etc., etc.) can be mounted in the machine to obtain different finishing qualities.

The machine is built with components suitable for 'wet' processing, that is with the use of coolant which cools down the parts being processed, preventing them from deforming and guaranteeing a longer life for the abrasive belt as well as obtaining very high quality finishes.

The wet system is particularly suitable for the satin finishing of non-ferrous materials such as stainless steel, aluminum, copper, bronze, brass and also titanium, which have characteristics of high thermal conductivity especially when it comes to tubular with thin thicknesses.

The operator has the possibility to choose via the electric panel positioned at the front of the machine, whether to carry out 'wet' or 'dry' machining.

The roller tables can be added to the machine, both on entrance and on exit, as it was designed specifically with the fixed-height conveyor belt to facilitate the processing of bars and long parts.

The machine can be equipped with various options as well as all the various standard equipments that you can see in the sections below.

| Power supply | 400 | 50 | 3 | Volt | Hz | Phase |

| Motor power | 4,0 ( 5,5 ) | kW ( hp ) |

| Motor speed | 1500 | tr/min |

| Overall dimension (Width x Depth x Height) | 1250 x 1200 x H. 2100 | mm |

| Weight standard machine | 625 | kg |

| Quantity of abrasive belt | 1 | No. |

| Abrasive belt dimension (wide x length) | 300 x 1900 | mm |

| Peripheral speed | 8 | m/sec |

| Dimensions of grooved rubberized driving wheel (wide x diameter) | Ø100 x 300 | mm |

| Belt conveyor dimension | 300 x 1900 | mm |

| Feeding speed of workpiece | min. 1 ÷ max. 10 | m/min |

| Workpiece thickness allowed | min. 1 ÷ max. 200 | mm |

| Workpiece length allowed | min. 140 ÷ max. 6000 | mm |

| Workpiece width allowed | max. 300 | mm |

The pneumatic tensioning of the abrasive belt is done by means of a pneumatic piston that maintains the belt tension constant, preventing the operator from checking and performing tensioning during processing. It also allows the quick replacement of the abrasive belts, particularly useful when performing operations that require frequent changes necessary to obtain fine finishing. The alignment of the belt takes place in front of the machine by means of an Allen wrench, inserted in the slot of the door window, which acts on a fine-pitch screw that allows precise adjustment of the tape centering.

The compressed air treatment unit is composed of an air filter, a pressure regulator and a safety solenoid valve that stops the machine in the event of a failed supply of compressed air.

The low voltage electrical panel is positioned on the front of the machine to make it easier for the operator to control the machine during processing.It is equipped with an ammeter to display the grinding pressure, motor brake unlock button, abrasive belt selector, feed selector, refrigeration system selector, lockable main switch, emergency stop button, safety door switch and an anti-restart in the event of a power failure for protection against unexpected start-ups.

The electric motor of the abrasive belt is equipped with a mechanical brake for a timely stop of the machine both in case of emergency and in the normal shutdown of the machine, guaranteeing greater operator safety.

The conveyor belt is moved by a gearmotor with a mechanical variator to adjust the advancement speed of the parts from 1 to 10 m/min.

The blowing device connected to the compressed air system creates an air blade useful for cleaning and drying the conveyor belt during processing.

The system for the coolant (water + grinding oil) is equipped with a collection tank with a capacity of 70 liters, an electric pump for continuous recirculation into the machine, a triple filter system for maximum cleaning of the coolant before to be reused.

5 liter can of oil-additive specific for grinding, with high cooling power of the parts being worked and lubrication of the mechanical parts. Useful at the first running of the machine for wet processing. It is to be added with 2-3% mixture to the normal tap water poured into the collection and recirculation tank of the machine.

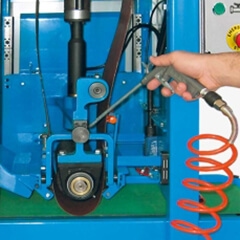

The gun connected to the tank of the cooling system is useful for washing and daily cleaning of the machine.

The position indicator with centesimal sensitivity (0.01 mm) is necessary for a precise adjustment of the grinding pass as well as useful for adjusting the height of the machine based on the thickness of the part to be processed. When the thickness changes, it is necessary to act on the handwheel that performs the movement of the grinding unit with respect to the conveyor belt.

The emergency device positioned at the entrance makes it possible to stop the machine if the operator inserts a workpiece with a thickness greater than that set on the machine, avoiding damage to the machine components such as the grooved rubber wheel, the conveyor belt and the abrasive belt.

The suction hood (80 mm diameter) is essential for dry machining as it will have to be connected to a powerful vacuum cleaner in order to keep the conveyor belt clean.

The rubberized contact wheel is grooved (hardness 60 Shore) for better traction of the abrasive belt and greater removal of the workpiece material. Before being mounted in the machine it is grinded on grinding machine for a homogeneous rotation and better processing at any cutting speed.

The abrasive belt with anti-elongation support specific for wet processing is mounted in the machine ready for use.

The strong base is fitted with anti-vibration damping support feet which allow leveling of the machine perfectly and to minimize vibrations during machining.

Extra charge for the addition of the inverter for the electronic adjustment of the abrasive belt speed from 150 to 3000 rpm and of the electric panel equipped with potentiometer, digital display and electric panel cooling filters. The inverter allows the operator to adjust the grinding speed most suited of the type of material and of the finishing level to be obtained.

Extra charge for the replacement of the standard motor (1500 rpm) with a two-speed motor 1400-2800 rpm and electrical panel equipped with selector.

The drying device is a fan that creates an air blade and allows the drying of workpieces at the outgoing.

Roller table of workpieces support at entrance and/or exit adjustable with four self-leveling feet. It is equipped with rubber coated rollers to avoid damaging the machined parts. It is complete with drainer to contain the coolant and return it to the tank in addition to keeping the working environment clean.

It is possible to mount different contact wheels into the machine according to the types of machining to be performed. We can supply smooth rubber wheels, grooved with different types of grooves, different hardness of rubber coating (Shore) as well as coatings in different materials (black vulcanized rubber, vulkollan etc.).

This equipment is an automatic filtration device for the coolant. It is equipped with a collection tank with a capacity of 170 liters and an electric pump for continuous recirculation in the machine. Automatic filtration takes place by means of a float which detects when the filtering fabric is dirty and can no longer filter and at that point advances the carpet and replaces the dirty filtering fabric with a new one without the need for operator intervention.

Wheeled dust extractor with cyclone system. It is built entirely of steel and has no dust filter bag. The suction takes place by means of the centrifugal force generated by the cyclone which conveys the dust into the underlying steel drawer that collects and holds it. In the case of dry machining it is necessary to connect the machine to a strong vacuum cleaner such as this which keeps the conveyor belt clean from the emery.

Specific abrasive belt for wet working.Various grains: P36÷P400

Specific 'Scotch-brite' belt for wet working. Various grains.