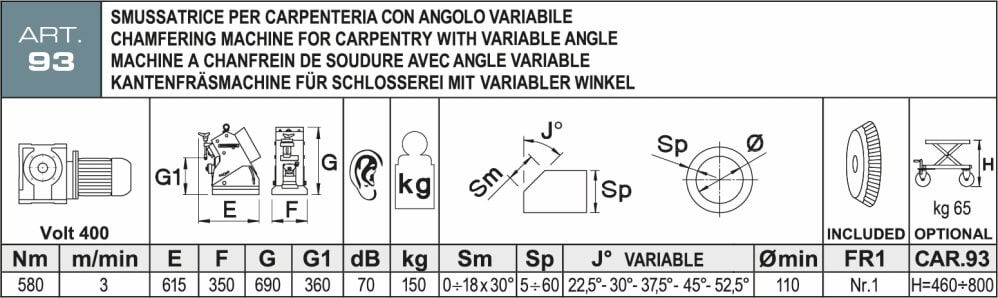

| Power supply | 400 | 50 | 3 | Volt|Hz|Phase |

| Motor power | 1,1 (1,5) | kW ( hp ) |

| Motor speed | 1400 | tr/min |

| Acoustic emission | 70 | dB |

| Overall dimension (Width x Depth x Height) | 350 x 615x H. 690 | mm |

| Weight standard machine | 150 | kg |

| Feeding speed of workpiece | 3 | m/min |

| Gearmotor power | 580 | N*m |

| Bevel dimension (diagonal) | 0 ÷ 18 | mm |

| Bevel angle | 22,5 - 30 - 37,5 - 45 -52,5 | ° |

| Workpiece thickness allowed | 5 ÷ 60 | mm |

| Workpiece diameter allowed | 110 | mm |

| Milling cutter diameter | 93 | mm |

| Workpiece width allowed | 80 | mm |

| Workpiece length allowed | 200 | mm |

Electrical panel low voltage with padlockable main switch and emergency stop button with electronic motor braking for a quick stop of the machine.

Electronic reversing of the direction of travel for partial sheet metal chamfering.

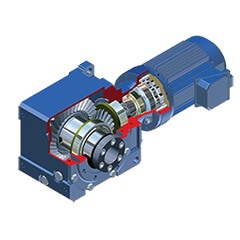

It mounts on a sturdy structure a powerful and resistant gearmotor designed to absorb and minimize the strong stresses subjected during the life of the machine.

22.5 ° - 30 ° - 37.5 ° - 45 ° - 55.5 ° at any time without the need for any accessories.Graduated vernier for head adjustment, horizontal rearrangement of the machine and sheet thickness.

The miller is specially designed with a toothed edge, such that it is suitable for automatic advancement. The miller included with the machine is suitable for chamfering iron materials and with a tensile strength of 45 kg / mm2

With a simple passage with the supplied accessory, the machine is capable of chamfering round pipes, having a minimum diameter of 100 mm; making grooves at the top of the tube.

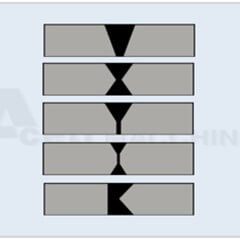

The forms of possible joints are:V; X; Y; double Y and K.