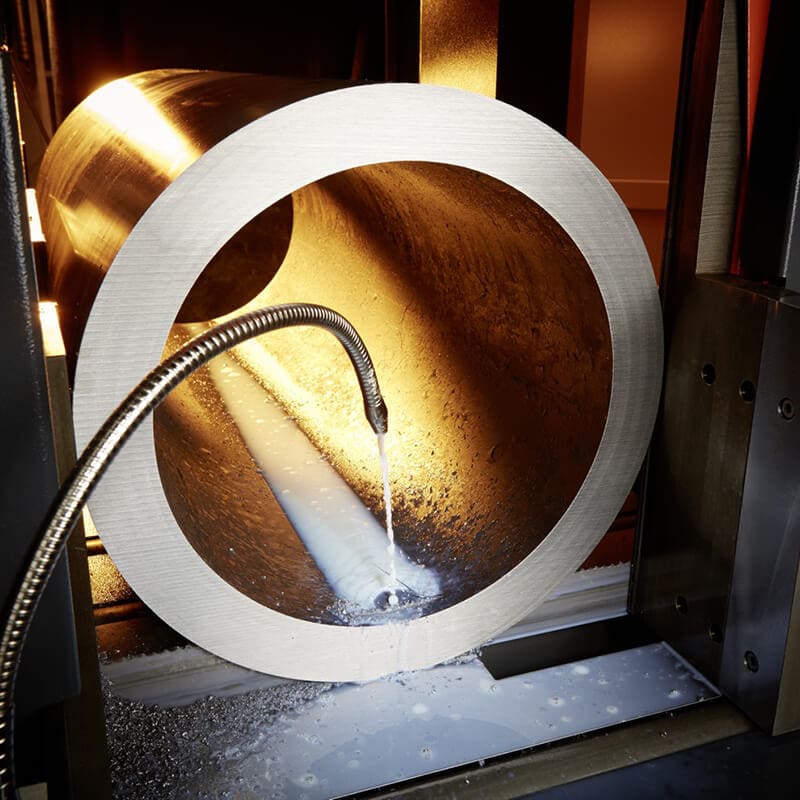

This automatic high-performance bandsawing machine has been especially designed for machining tubular material. With a saw feed rotated through 180 degrees, this fully automatic machine works in a particularly efficient way to reduce wear on the cutting tools. An infinitely variable electro mechanic saw feed with servomotor and ball bearing spindle, working from the bottom to the top, offers the best conditions for an efficient, sensitive and tool-saving cutting operation.

The standard precise linear guides (re-circulating ball units with grease lubricated guide carriage) guarantee maximum life.

The standard AdvancedControl offers the optimum operation of the machine.

Easy and clearly arranged job entry via job wizard. The precise drive via ball bearing spindle in material feed guarantees an accurate material length positioning.

| Shape | |

| Cutting range 90° | 520 mm x 560 mm / 520 mm (22.04 x 20.47 in / 20.47 in) |

| Minimum cut length approx. | 25 x 25 mm (0.98 x 0.98 in) |

| Minimum remnant length in automatic operation (possible only if the material has a perfect geometric surface) | 50 mm (1.96 in) |

| Minimum remnant length in single cut operation | 25 mm (0.98 in) |

| Length approx. | 1.705 mm (67.13 in) |

| Width approx. | 3.339 mm (131.45 in) |

| Height | 2.277 mm (89.64 in) |

| Total weight approx. | 3.800 kg (8377 lbs) |

| Material support height | 700 mm (27.56 in) |

| Connected load | 8,0 kW (10.72 HP) |

| Saw motor, frequency controlled | 5,5 kW (7.37 HP) |

| Cutting speed infinitely variable | 12 - 150 m/min (39.37 - 492.13 ft/min) |

| Material feed length – individual feed | 500 mm (19.69 in) |

| Multiple feed | 9.999 mm (393.66 in) |

| Saw blade dimensions | 7.067 x 54 x 1,6 mm (277.95 x 2.13 x 0.63 in) |

| Saw blade dimensions option 1 | 7.067 x 54 x 1,3 mm (277.95 x 2.13 x 0.50 in) |

| Cutting feed | electrically adjustable via ball bearing spindle |

| Material Feed | ball bearing spindle |

| Material clamping | hydraulic |

| Saw blade cleaning | by easy to exchange wire brush |