The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for splashing. It provides lubrication and cooling functions, ensuring no dust deposit and saw blade, high cutting accuracy and long service life of saw blade.

| Model | Lesther J-20 36 |

|---|---|

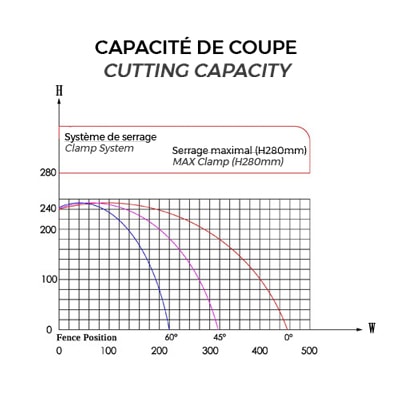

| Cutting Angle | +45° ~ 0° ~ -45° |

| Saw Blade Sizes | 36" x 50 mm(bore) |

| Spindle Speed | 936 R.P.M.(60 HZ) 862 R.P.M.(50 HZ) |

| Motor | 10 HP (6P) |

| Air Pressure | 4-6 kgs/cm² |

| Table Area | 1,500 x 770 mm |

| Table Height Form Floor | 1,220 mm |

| Net/Gross Weight | 1,800 / 2,300 kgs |

| Machine Dimensions (L x W x H) | 1,770 x 1,580 x 2,520 mm |

| Packing Dimensions (L x W x H) | 1,900 x 1,700 x 2,230 mm |