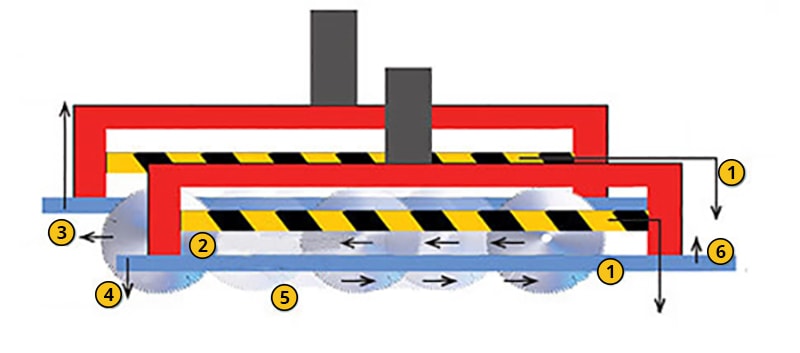

Specially designed cutting way:After the saw blade moves forward for cutting, table moves to right and left for retracting 2 mm.Then the saw blade return to its home position. This special design may avoid return-cutting, while ensuring fine surface of cut and cutting accuracy.

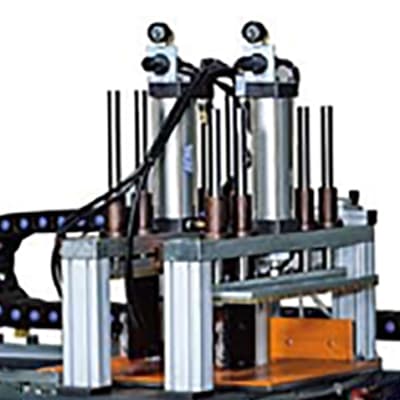

The clamps on the feed table are suited for cutting irregular stock without need of additional fixtures to fix the work piece.

Auxiliary support prevents work piece deflection.

Employs precision ground rack with accuracy up to 0.02mm ( suitable for 3 and 6 meter feed travel )

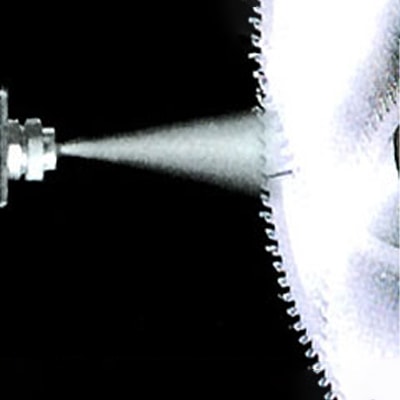

The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for spraying. It provides lubrication and cooling functions, ensuring no dust deposit and saw blade, high cutting accuracy and long service life of saw blad.

| Model | LESTHER J-NC24L (Original Model For J-455L) | LESTHER J-NC30L | LESTHER J-NC36L | LESTHER J-NC24 LB | LESTHER J-NC24 LG | LESTHER J-NC24 LS |

|---|---|---|---|---|---|---|

| Servo Drive System | Ball screw (or high precision gear rack) | Ball screw (or high precision gear rack) | Ball screw | Ball screw | High precision gear rack | Ball screw |

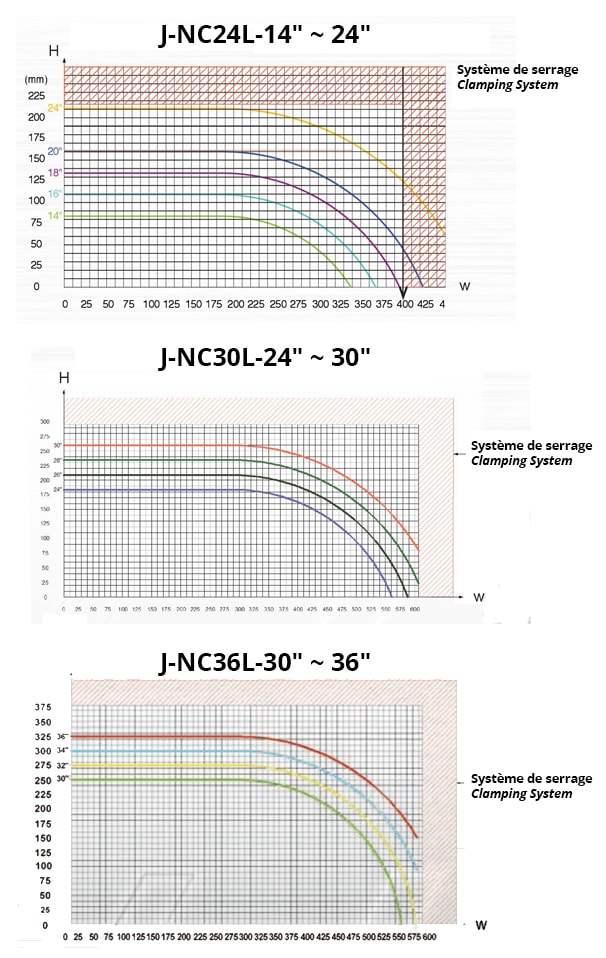

| Cutting Capacity ( H x W ) - Depends on saw blade size, Check cutting capacity chart | 200 x 200, 175 x 210, 130 x 350, 40 x 400 mm | 250 x 250, 210 x 400, 180 x 500 mm | Circle :Ø320, Square:100 x 550, 200 x 500, 300 x 300 mm |

200 x 200, 175 x 210, 130 x 350, 40 x 400 mm | 200 x 200, 175 x 210, 130 x 350, 40 x 400 mm | 200 x 200, 175 x 210, 130 x 350, 40 x 400 mm |

| Max. Feed Distance(one cycle) | 1,000 mm ( 2,500 / 6,000 mm opt. ) Unlimited recycle feed distance | 1,000 mm ( 2,500 / 6,000 mm opt. ) Unlimited recycle feed distance | 1,000 mm ( 2,500 / 6,000 mm opt. ) Unlimited recycle feed distance | 2,500 mm (Unlimited recycle feed distance) | 6,000 mm (Unlimited recycle feed distance) | 1,000 mm (Unlimited recycle feed distance) |

| Saw Spindle Speed | 1,500 - 3,500 R.P.M . (Depends on saw blade size to set) |

1,000 ~ 3,000 R.P.M . | 900 ~ 1,500 R.P.M. | 1,500 ~ 3,500 R.P.M. (Depends on saw blade size to set) | 1,500 ~ 3,500 R.P.M. (Depends on saw blade size to set) | 1,500 ~ 3,500 R.P.M. (Depends on saw blade size to set) |

| Saw Spindle Motor | 15 HP (4 P) | 15 HP(4 P) | 20 HP(4 P) | 15 HP (Level 4) | 15 HP (Level 4) | 15 HP (level 4) |

| Inverter | 15 HP | 15 HP (opt.20HP) | 20 HP | 15 HP (opt.20HP) | 15 HP (opt.20HP) | 15 HP (opt.20HP) |

| Hydraulic Feed Motor | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP | 1 kw servomotor |

| Feeding Servomotor |

1 kw (Optional 1.5 kw) | 2 kw | 2 kw | 2 kw | 2 kw | 1kw (Optional 1.5 kw) |

| Table Height From Floor | 920 mm | 1,010 mm | 1,110 mm | 920 mm | 920 mm | 920 mm |

| Touch-Sensing Screen | 7" | 7" | 7" | 7" | 7" | 9.7" |

| Saw Blade Size | Choice of 12" ~ 24" (1" bore) | 24” ~ 30” (50 mm bore) | 30” ~ 36” (50 mm bore) | Choice of 12" ~ 24" (1" bore) | Choice of 12" ~ 24" (1" bore) | Choice of 12" ~ 24" (1" bore) |

| Air Pressure | 4 ~ 6 kgs / cm2 | 4 ~ 6 kgs / cm2 | 4 ~ 6 kgs / cm2 | 4 ~ 6 kgs / cm2 | 4 ~ 6 kgs / cm2 | 4 ~ 6 kgs / cm2 |

| Max. Load | 100 kgs | 200 kgs | 250 kgs | 100 kgs | 100 kgs | 100 kgs |

| Machine Dimensions (L x M x H) | 3,700 x 1,970 x 1,870 mm | 3,900 x 2,290 x 1,940 mm | 4,200 x 2,290 x 2,030 mm | 5,800 x 1,970 x 1,870 mm | 8,300 x 1,970 x 1,870 mm (For 6.5m size) | 3,700 x 1,970 x 1,870 mm |

| Packing Dimensions (L x M x H) | 3,800 x 2,070 x 1,970 mm | 4,000 x 2,390 x 2,040 mm | 4,300 x 2,390 x 2,130 mm | 5,900 x 2,070 x 1,970 mm | 8,400 x 2,070 x 1,970 mm (For 6.5m size) | 3,800 x 2,070 x 1,970 mm |

| Net / Gross Weight | 2,835 / 2,920 kgs | 2,800 / 3,100 kgs | 3,300 / 3,600 kgs | 3,300 / 3,500 kgs | 4,600 / 4,750 kgs | 2,835 / 2,920 kgs |