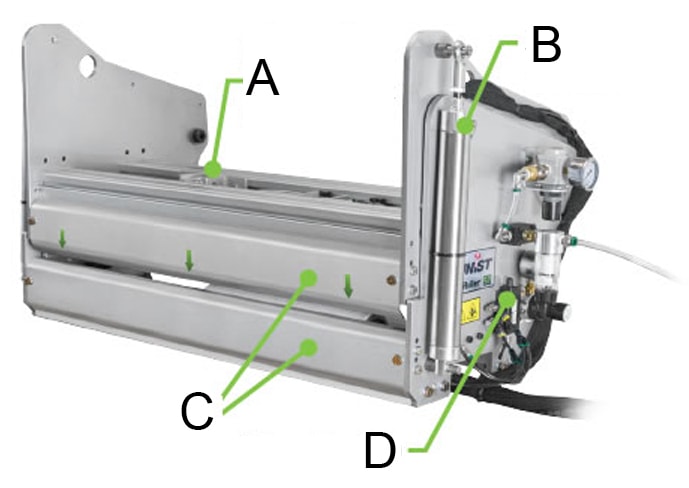

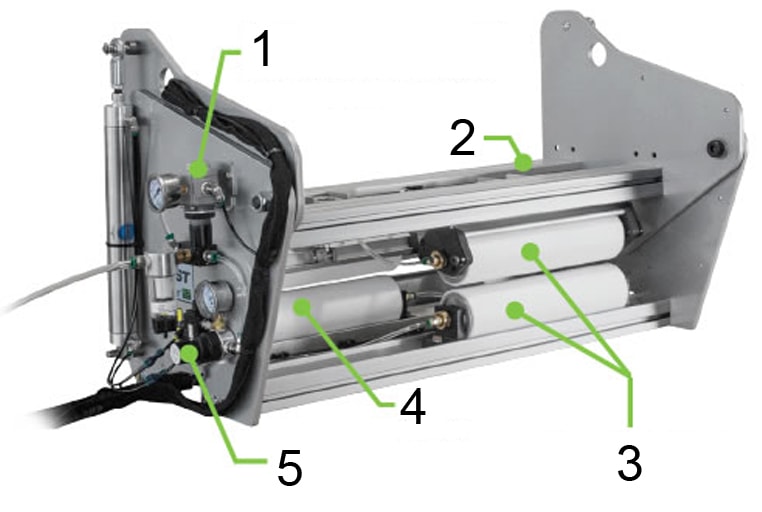

The Uni-Roller® S2 HG delivers the same smooth and consistent fluid application the industry has come to expect from Unist, and adds an articulating chassis. The upper rollers opens a full 6” [152 mm] to avoid deformities in the head or tail of coil stock, making loading easier and preventing damage to the lubricator itself.

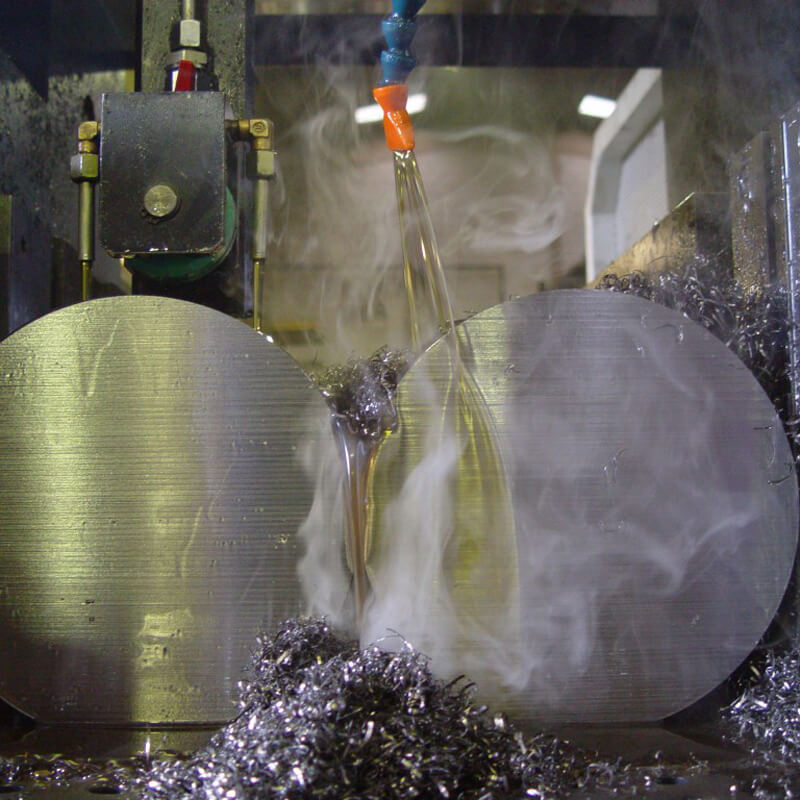

That's what many of our customers report. By applying the proper amount of fluid, the Uni-Roller® S2 Powered lubricator uses 50 to 90% less lubricant for stock lubrication. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

The brushed stainless steel guards protect the rollers and guide material when loading coil stock or feeding blanks. With the guards removed for better access, a roller can be changed in about a minute using a single wrench. The Uni-Roller® S2 HG is built to handle any manufacturing environment without sacrificing ease of maintenance.

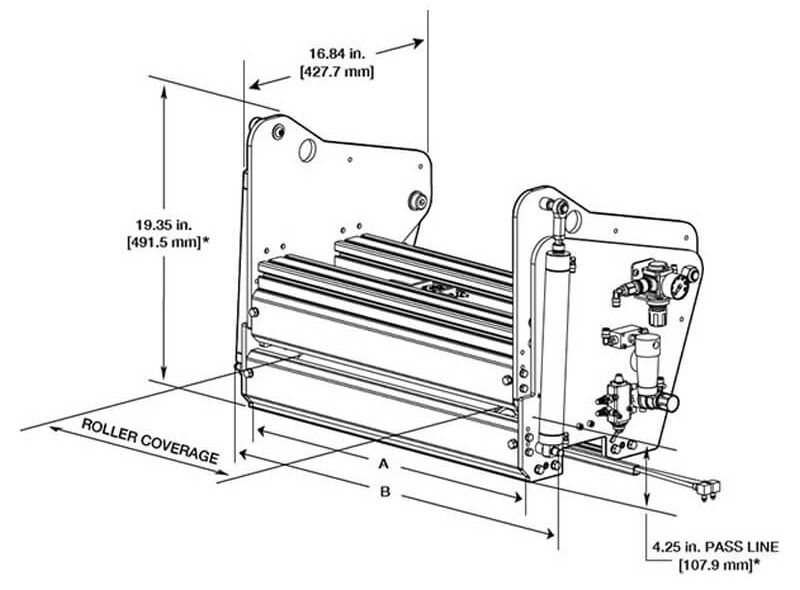

Single roller coverage up to 18" [457 mm]

Multiple rollers coverage over 18" [457 mm]

| Roller coverage | A (extrusion length) | B (overall width) |

|---|---|---|

| 12” [305 mm] | 19” [482.6 mm] | 25.18” [639.6 mm] |

| 18” [457 mm] | 25.00” [635.0 mm] | 31.18” [792.0 mm] |

| 23.5” [597 mm] | 31.00” [784.4 mm] | 37.18” [944.4 mm] |

| 35” [889 mm] | 43.00” [1092.2 mm] | 49.18” [1249.2 mm] |

| 46.5” [1181 mm] | 55.00” [1397.0 mm] | 61.18” [1554.0 mm] |

| 58" [1473 mm] | 67.00" [1701.8 mm] | 73.18" [1858.8 mm] |

| 69.5" [1765 mm] | 79.00" [2006.6 mm] | 85.18" [2163.6 mm] |

| Stock type | Coil stock |

| Stock thickness | 0.100”-.350” (2.54mm – 8.89mm) |

| Stock width | 3" - 72" and up (76mm - 1828mm). |

| Fluid type(s) | For use with a broad range of water soluble and neat lubricants. Viscosity from 30 – 1000 SUS. Thicker lubricants can be tested by Unist for compatibility. |

| Fluid supply | Pressurized 3 gal(11.4L), 6 gal(22.7L), 15 gal(56.8L), 30 gal(113.6L) tank. Also 20 gal(75.7L) poly tank with diaphragm pump. |

| Applicator material | Polyester felt or polyurethane foam |

| Controller | SmartFlow |

| Power | NA |

| Mounting | 5/16-18 t-nuts supplied in bottom extrusion slots allow for multiple mounting options. 2 t-nuts per slot provided. |

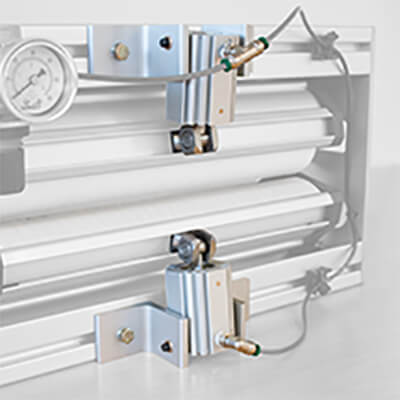

| Air | Clean, dry, compressed air, 80-100 psi (5.5-6.9 bar),10 SCFM (280 SLPM) minimum |

Reduces uneven wear on cover when a variety of stock widths and thicknesses are used. Due to limited fluid compatibility, consult Unist.

Extremely durable and compatible with a broad range of fluids.

For use in applications requiring coverage of 50 mg/ft2 [538 mg/m2] or less.

Ties into control systems to automate opening of roller set.

Manual open/close control of the roller set

Required for stock thicknesses over 0.25" [6.35 mm].

Preferred method for maintaining pressure on stock and opening the rollers to load a new coil.

Provides an input signal to an SPR-2000™ controller based on roller rotation. Select when an intermittent signal from press not available.

Allows for permanent spray nozzle mounting to the die. Ensures nozzles remain in correct position with each die change.

Your fluid application system needs a steady supply of pressurized fluid. Unist offers a broad range of options to meet your needs.

Best choice for most applications with the widest range of fluid compatibility and flow rate.