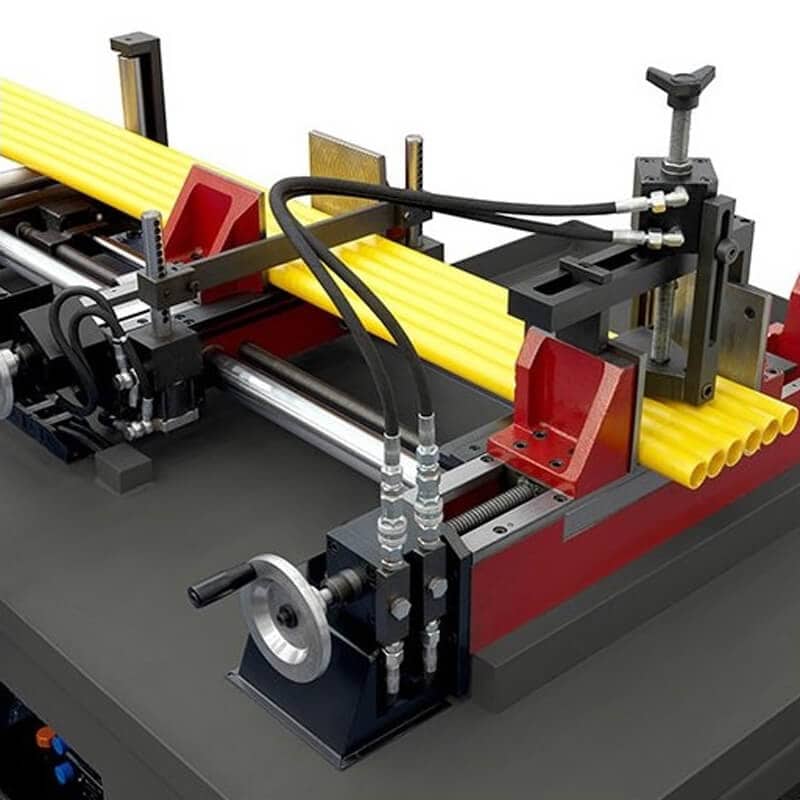

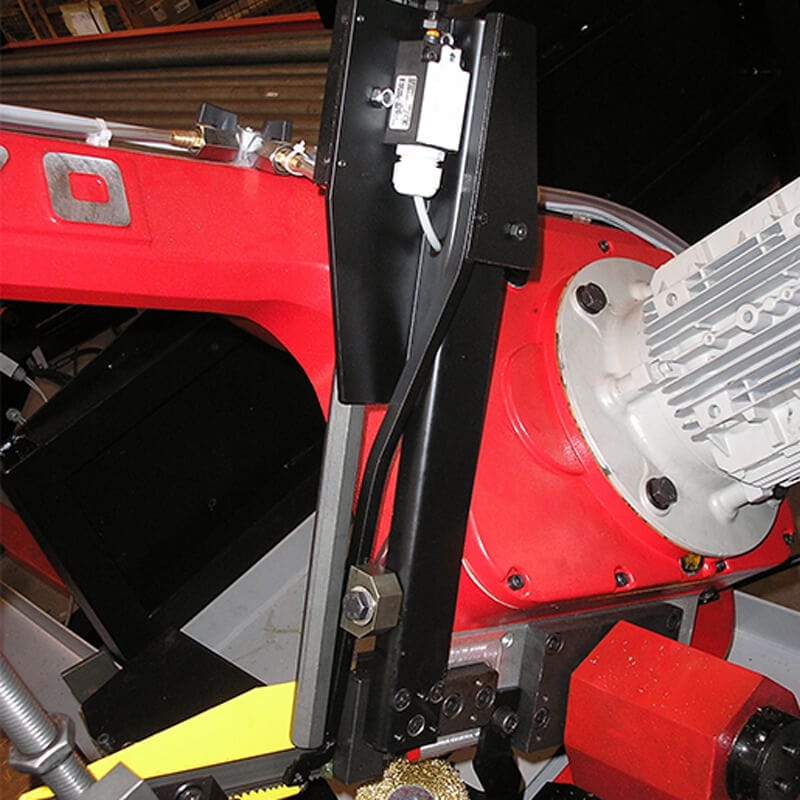

The Bianco 30.30 AF TC is a twin column automatic bandsaw machine, heavy construction for high working performance. 30° tilted blade wheels, zero mm scrap length. Bow, base and columns in steel construction, vertical bow descent on ball bearing guides, hydraulic blade tensioning controlled by limit switch, low noise hydraulic system, automatic bow fast up/down movements controlled by feeler pin. Laser light device for head and tail piece detecting. Down feed with infinitesimal adjustment. CNC to control all the machine functions and possibility to store up to 99 cutting programs. “Touch” version is equipped with a 7” touch screen control panel. The machine has perimetrical safety protection, double safety button for cycle start-up and low voltage electrical system according to EC rules.

| Ø | ⧄ | ||

|---|---|---|---|

| 90° mm | 300 | ⧄ | 300 × 150 |

| Blade | 140" x 1" x 0.035" 3560 x 27 x 0,9 mm |

||

| Blade Dimensions | 140" x 1" x 0.035" 3560 x 27 x 0,9 mm |

| Cutting Speed | 20 - 150 m/min |

| Working surface height | 830 mm |

| Blade motor | 1,5 kW (V400) |

| Hydraulic unit motor | 0,75 kW |

| Cooling Pump Motor | 0,12 kW |

| / Chip conveyor motor | 0,09 kW |

| Feeding carriage motor | 1,95 Nm (Brush-less) |

| Carriage stroke | 800 mm |

| Scrap length | 0 mm |

| Dimensions (L x W x H) | 187 x 210 x 180 cm |

| Transport dimensions (L x W x H) | 190 x 210 x 180 cm |

| Weight | 1400 Kg |