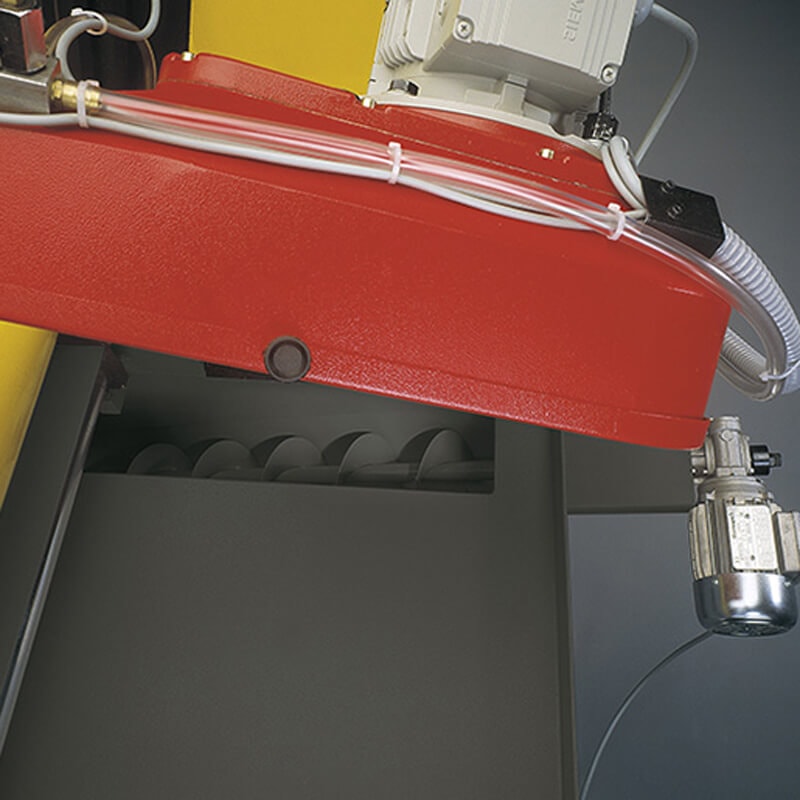

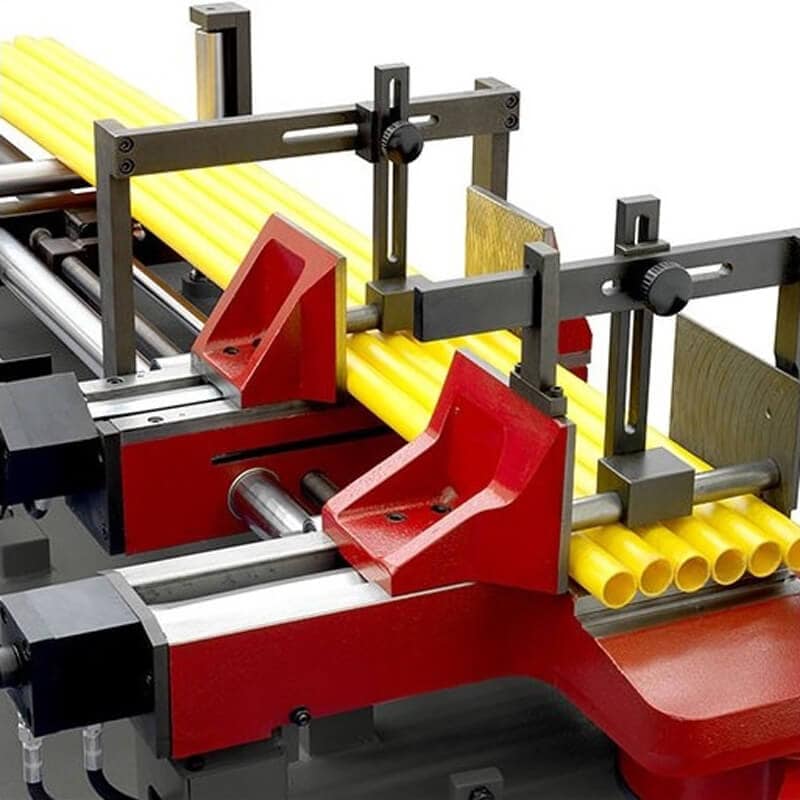

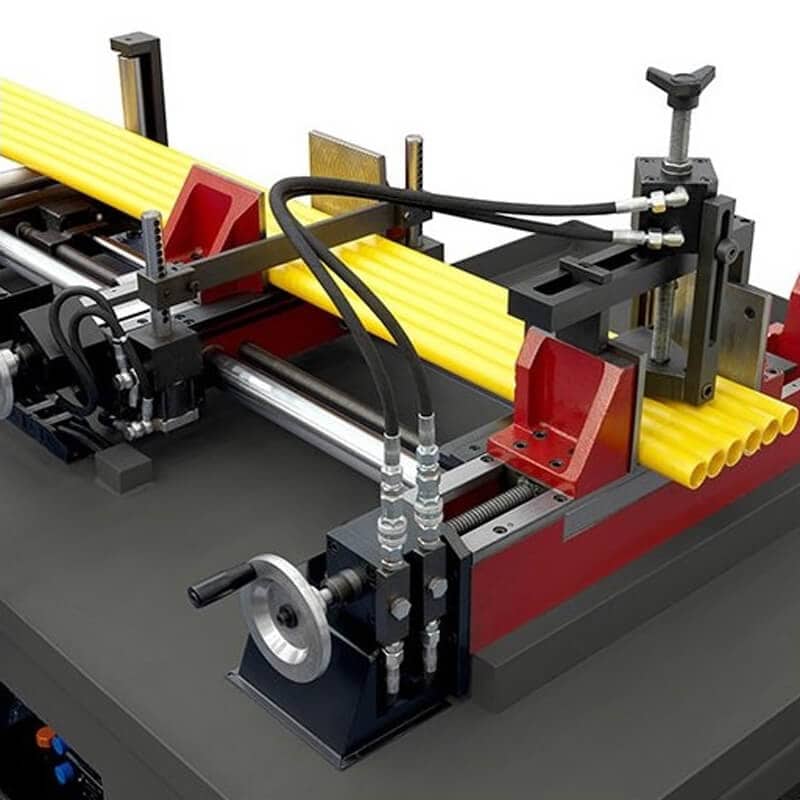

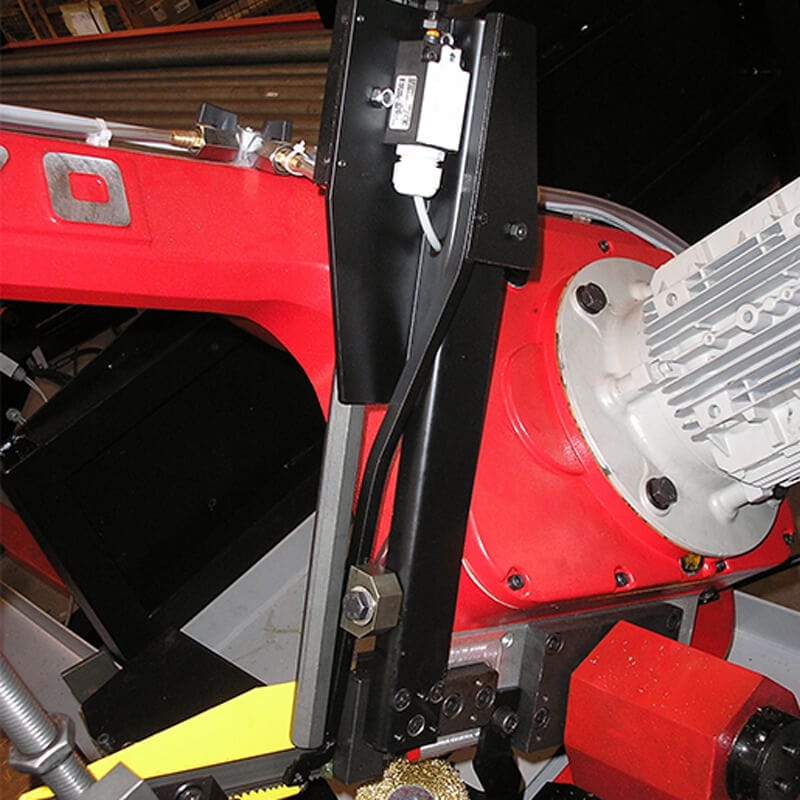

The Bianco 420 A is an automatic band saw machine equipped with hydraulic controlled bow, vice and material feeding.Downfeed with infinitesimal adjustment. Manual setting of the cutting length trough mechanical handle, quantity of pieces to be cut and all machine functions are operated and controlled by PLC. Automatic fast up/down bow movement controlled by feeler pin. The machine is equipped with perimetrical safety protection and a double safety button for cycle start-up. The sawing machine's low voltage electrical system was made according to EC rules.

We suggest you not to feed full material bigger than 150 mm Ø while the machine is operating in automatic mode.

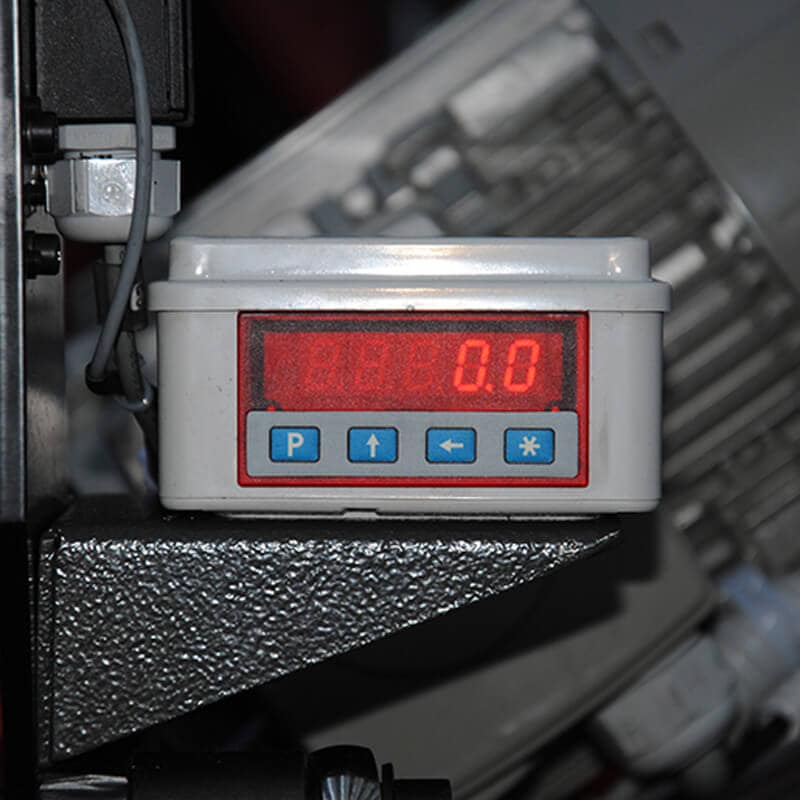

NC model can control all the machine functions and can store up to 99 cutting programs

Quantity of parts to be cut and machine functions controlled by CNC with the possibility of storing up to 99 cutting programs. Adjust the blade speed using the Frequency converter.

| Ø | ⧄ | ⍂ | |

|---|---|---|---|

| 90° mm | 300 | 240 | 420 x 200 |

| 45° mm | 240 | 230 | 270 x 140 |

| 60° mm | 170 | 170 | 170 x 170 |

| Blade | 128-1/2" x 1" x 0.035" 3270 x 27 x 0,9 mm |

||

| Standard PLC Model | CNC/TOUCH Model | |

|---|---|---|

| Blade Dimensions | 128-1/2" x 1" x 0.035" 3270 x 27 x 0,9 mm |

128-1/2" x 1" x 0.035" 3270 x 27 x 0,9 mm |

| Cutting Speed | 35 - 70 m/min | 20 - 100 m/min |

| Working surface height | 835 mm | 835 mm |

| Blade motor | 0,9 - 1,5 kW (V400) | 1,5 kW (V400) |

| Hydraulic unit motor | 0,37 kW | 0,37 kW |

| Cooling Pump Motor | 0,12 kW | 0,12 kW |

| Carriage stroke | 800 mm | 800 mm |

| Scrap length | 220 mm | 220 mm |

| Dimensions (L x W x H) | 322 x 205 x 190 cm | 322 x 205 x 190 cm |

| Transport Dimensions (L x W x H) | 240 x 170 x 170 cm | 240 x 170 x 170 cm |

| Weight | 1090 Kg | 1090 Kg |