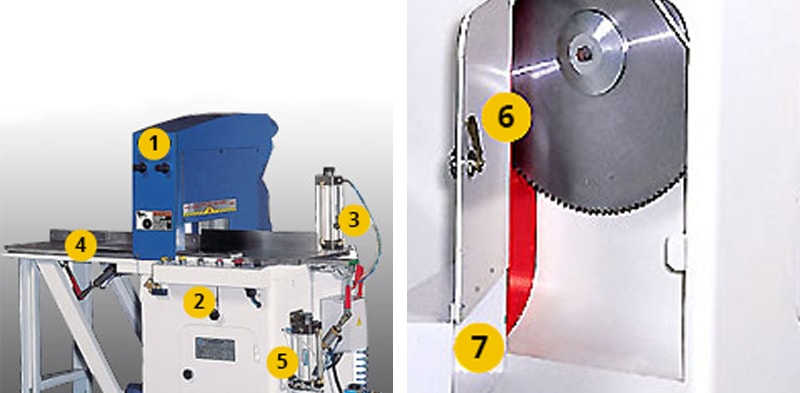

After the saw blade moves upward for cutting, table moves to right and left for retracting 2mm, then the saw blade lower to it's home position. This special design may avoid return-cutting. while ensuring fine surface of cut and cutting accuracy.

Two sets of hold down clamps on the worktable make the machine able to compact clamp the material, which is more suitable for cutting irregular stock. This design allows for independent adjustment of clamping speed and clamping pressure.

The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for splashing. It provides lubrication and cooling functions, ensuring no dust deposit and saw blade, high cutting accuracy and long service life of saw blade.

The saw blade spindle is heat treated and plated for greatly increasing the spindle life.

18'' Saw Blade x 1pce、Replace Saw Blade Toolbox

| Model | Lesther J-18P |

|---|---|

| Cutting Angle | 90 ° or 45 ° |

| Saw Speed | 18" x 1" bore |

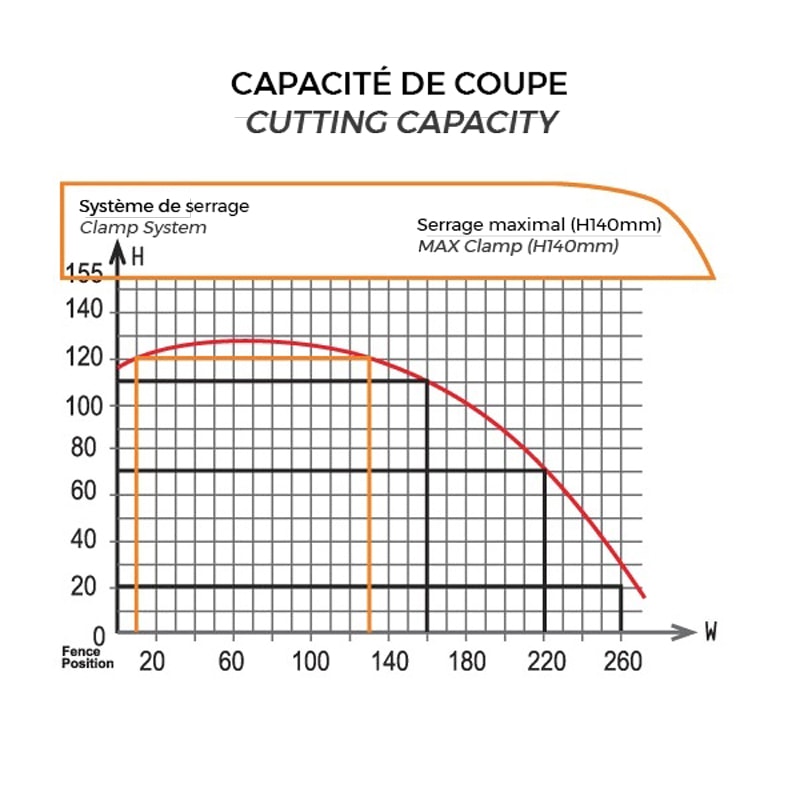

| Cutting Capacity (H x W) | 110 x 110, 100 x 180 20 x 260, 60 x 240 mm |

| Spindle speed | 3,200 R.P.M. |

| Saw Motor | 7.5 HP (10 HP opt.) |

| Air Pressure | 4 - 6 kgs/cm2 |

| Table Area (L x W) | 640 x 380 mm |

| Table Height From Floor | 875 mm |

| Conveyor Length (Opt.) | 1 - 7 M |

| Net/Gross Weight | 600 / 750 kgs |

| Machine Dimensions (L x W x H) | 1,500 x 840 x 1,460 mm |

| Packing Dimensions (L x W x H) | 1,620 x 960 x 1,660 mm |