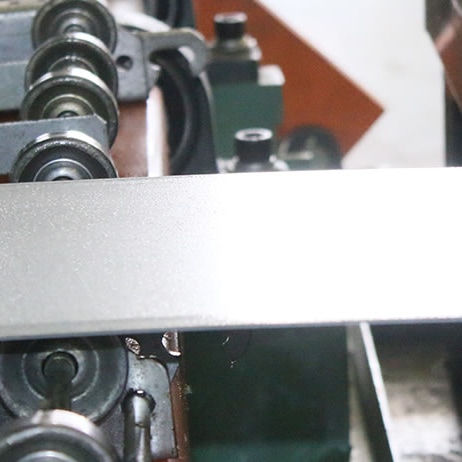

The Mini-Roller™ applies the correct amount of fluid for your small press window and high-speed, short feed length applications when combined with a SmartFlow® programmable fluid controller. This 1 to 6 in. wide (25 mm to 152.4 mm) unit consistently applies the correct amount of fluid and lets you start saving now.

On average, a Unist system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

That's what many of our customers report. By applying the proper amount of fluid, the Uni-Roller® lubricator uses 50 to 90% less lubricant. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

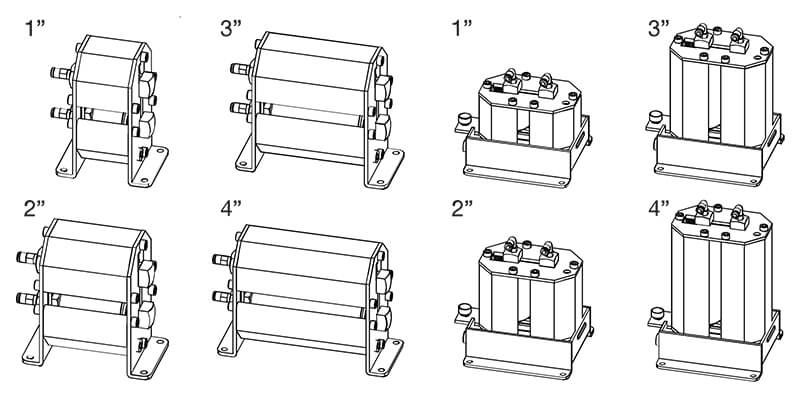

The Horizontal model uses a fluid controller to inject lubricant into a dispenser tube inside the roller. Small holes in the tube evenly distribute the lubricant along the length of the roller.

The Vertical model uses a baffle positioned inside each of the rollers near the top. Every time the fluid controller injects lubricant into the dispenser tube, the fluid spreads across the baffle and is redirected to the outside of the roller. Gravity pulls fluid down the length of the cover.

Both vertical and horizontal Mini-Rollers™ are available in 1" (25mm), 2" (51mm), 3" (76mm), 4" (102mm), and 6" (152.4mm) widths

Polyester felt (standard)

Extremely durable and compatible with a broad range of fluids

Polyurethane foam cover (optional)

For use with vanishing oils and with thin stock which is narrow compared to overall roller width. Limited fluid compatibility, please contact Unist before selecting this option.

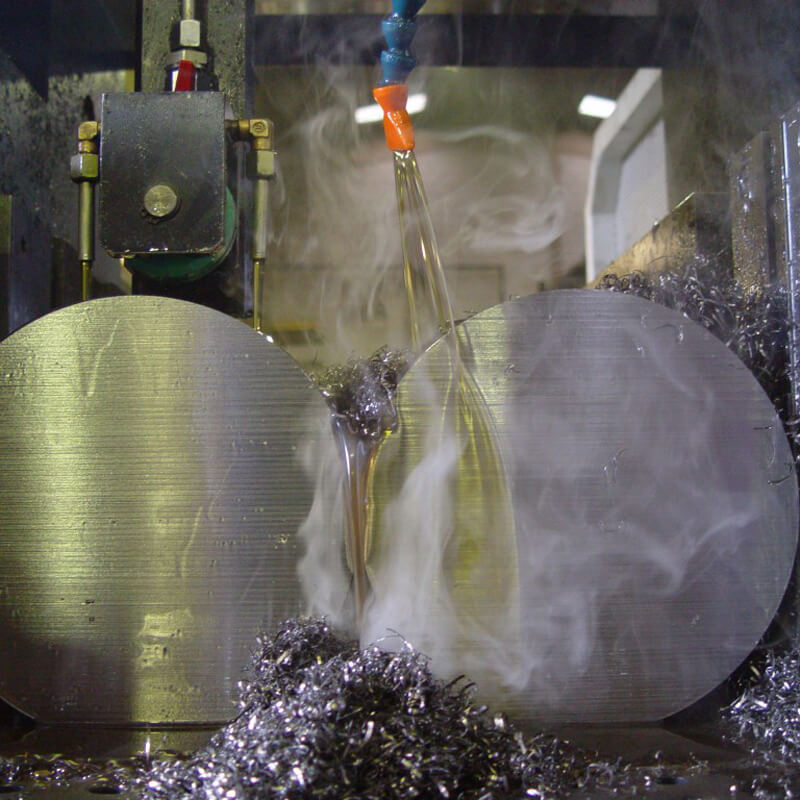

The internally-supplied rollers are essential to precisely applying the fluid. Inside each of the rollers is a dispenser tube with small holes placed along its length. Fluid is injected into the dispenser tubes from the fluid controller and dispensed across the inside of the rollers. The lubricant is transferred to the stock through durable polyester felt or polyurethane foam roller covers. These cover materials apply the lubricant smoothly and evenly across both the top and bottom of the stock.

The Uni-Roller® S2 Powered applies the exact amount of lubricant required. This eliminates the mess and waste associated with in-die spray systems and externally lubricated roller systems. The result is not only a cleaner shop, but also significant savings from decreased fluid waste, improved die life, better part quality and increased machine up-time. Many customers have reported savings resulting in a return on investment of less than six months!

| Stock type | Narrow coil stock |

| Stock thickness | .002" - 0.060" (.05mm – 1.52mm) |

| Stock width | 0.5" - 6" (12.7mm – 152.4mm) |

| Fluid type(s) | For use with a broad range of water soluble and neat lubricants. Viscosity from 30 – 1000 SUS. Thicker lubricants can be tested by Unist for compatibility. |

| Fluid supply | Pressurized 3 gal (11.4L), 6 gal (22.7L), 15 gal (56.8L), 30 gal (113.6L) tank. Also 20 gal (75.7L) poly tank with diaphragm pump. Also can be integrated into customer’s bulk fluid system |

| Applicator material | Polyester felt or polyurethane foam |

| Controller | SmartFlow |

| Power | NA (see SmartFlow® for controller power requirements) |

| Mounting | Integral mounting flange with thru-holes for #10 bolts |

Reduces uneven wear on cover when a variety of stock widths and thicknesses are used. Due to limited fluid compatibility, consult Unist.

Extremely durable and compatible with a broad range of fluids.

Provides an input signal to an SPR-2000™ controller based on roller rotation. Select when an intermittent signal from press not available.

Allows for permanent spray nozzle mounting to the die. Ensures nozzles remain in correct position with each die change.