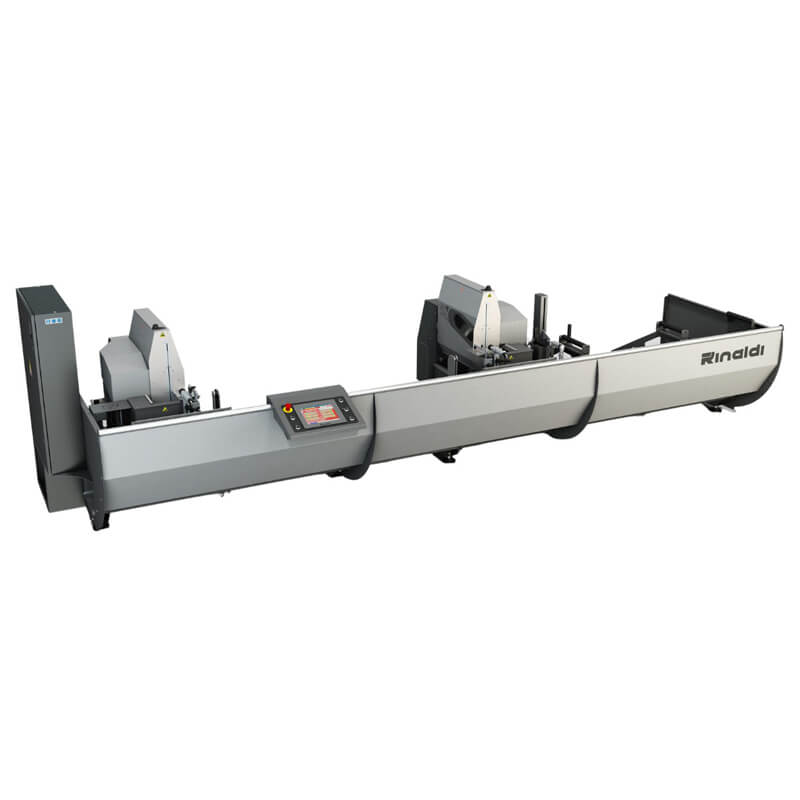

Front double-head cutting-off machine with NC controlled automatic movement of the mobile head, external and internal head tilting from 22.5 to 135° and all intermediate degrees with electronic numeric control. Hydraulic blade feed with 15° tilting angle. Front casing with shaving collection tray; full cutting area protection, elevating, with pneumatic control. Profile support roller conveyor connected to the mobile head which compacts inside the casing. Available in two working cut lengths: 4 m or 5 m.

| Three-phase power supply | 380/400-50/60 | Volt-Hz |

| Three-phase motor power | 2.2 | kW |

| Blade rotation speed | 2850 | rpm |

| Diamètre lame | 550 | mm |

| Head positioning speed | 25 | m/min. |

| Working cut (according to version) | 4000-5000 | mm |

| Minimum cut 135°-90°/ 22.5° | 200/300 | mm |

| Adjustable external head tilt angle | 90...22.5 | ° |

| Adjustable internal head tilt angle | 90...135 | ° |

| Weight (according to version) | 1750-1900 | kg |