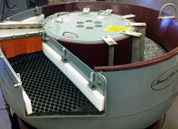

The HR is a heavy duty machine that can be customized with a wide variety of standard and special options that gives the customer a full range of processing possibilities – from minimal human involvement to a fully automatic system for a hands off operation.

The workhorse of the Spiratron® family of vibratory finishing machines, the HR Series has evolved since its original patent notoriety of being the first round bowl internal separation machine. The HR is a heavy duty machine that can be customized with a wide variety of standard and special options that gives the customer a full range of processing possibilities – from minimal human involvement to a fully automatic system for a hands off operation.

HR Series Machines are vibratory finishing machines that can be customized from a basic stand alone vibratory machine, into a complete multi-featured finishing cell. The options can be single add-ons or very complex system additions to the machine to ensure that they operate flawlessly and continuously to meet the customers needs.

| MODEL | Total Capacity L (cu.ft.) | Max Working Capacity L (cu.ft.) | Overall Diameter mm (in.) | Overall Height mm (in.) | Process Channel Width mm (in.) | Center Column Diameter mm (in.) |

|---|---|---|---|---|---|---|

| HR-3 SL CL | 165 (5.5) | 75 (2.5) | 1066 (42) | 1092 (43) | 190 (7.5) | 660 (26) |

| HR-5 SL CL | 300 (10.71) | 150 (5) | 1236 (48.7) | 1181 (46.5) | 259 (10.2) | 660 (26) |

| HR-11 SL CL | 601 (20.4) | 300 (10) | 1555 (61.25) | 1320 (52) | 317 (12.5) | 850 (33.5) |

| HR-17 SPT | 990 (33.1) | 381 (15) | 1178 (70) | 1346 (53) | 381 (15) | 965 (38) |

| HR-17 CPT | 990 (33.1) | 340 (12) | 1178 (70) | 1346 (53) | 381 (15) | 965 (38) |

| HR-23 SPT CPT | 1500 (50.3) | 540 (18) | 1930 (76) | 1346 (53) | 457 (18) | 965 (38) |

| HR-29 SPT CPT | 1699 (60.0) | 2032 (80) | 1619 (63.75) | 508 (20) | 965 (38) | |

| HR-60 SPT | 1472 (52) | 1530 (51) | 2743 (108) | 2032 (80) | 558 (22) | 1549 (61) |

| HR-100 SPT | 6720 (224) | 2460 (82) | 3048 (120) | 2184 (86) | 685 (27) | 1549 (61) |

| MODEL | Screen Deck Width mm (in.) | Screen Deck Height mm (in.) | Base Diameter mm (in.) | Drain Sizes mm (in.) / # of Drains | Motor Horse Power kw (HP) | 460 Volts Amp Load | 230 Volts Amp Load | Aprox Shipping Weight kg (lbs.) |

|---|---|---|---|---|---|---|---|---|

| HR-3 SL CL | 152 (6) | 939 (37) | 1041 (41) | 101.6 (4) / 1 | 2.2 (3) | 7.8 | 12.6 | 997.9 (2,200) |

| HR-5 SL CL | 203 (8) | 873 (39) | 1193 (47) | 101.6 (4) / 3 | 2.2 (3) | 7.8 | 12.6 | 1360.8 (3,000) |

| HR-11 SL CL | 279 (11) | 1066 (42) | 1448 (57) | 101.6 (4) / 3 | 5.6 (7.5) | 14 | 25 | 2267.9 (5,000) |

| HR-17 SPT | 330 (13) | 1016 (40) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2494.7 (5,500) |

| HR-17 CPT | 330 (13) | 1016 (40) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2492.7 (5,500) |

| HR-23 SPT CPT | 381 (15) | 1066 (42) | 1702 (67) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2812.2 (6,200) |

| HR-29 SPT CPT | 432 (20) | 1245 (49) | 1676 (66) | 101.6 (4) / 3 | 7.5 (10) | 17 | 31 | 2993.7 (6,600) |

| HR-60 SPT | 482 (19) | 1473 (58) | 2642 (104) | 101.6 (4) / 3 | 22.3 (30) | 43 | 83 | 5443.1 (12,000) |

| HR-100 SPT | 609 (24) | 1575 (62) | 2642 (104) | 101.6 (4) / 3 | 22.3 (30) | 43 | 83 | 9298.6 (20,500) |