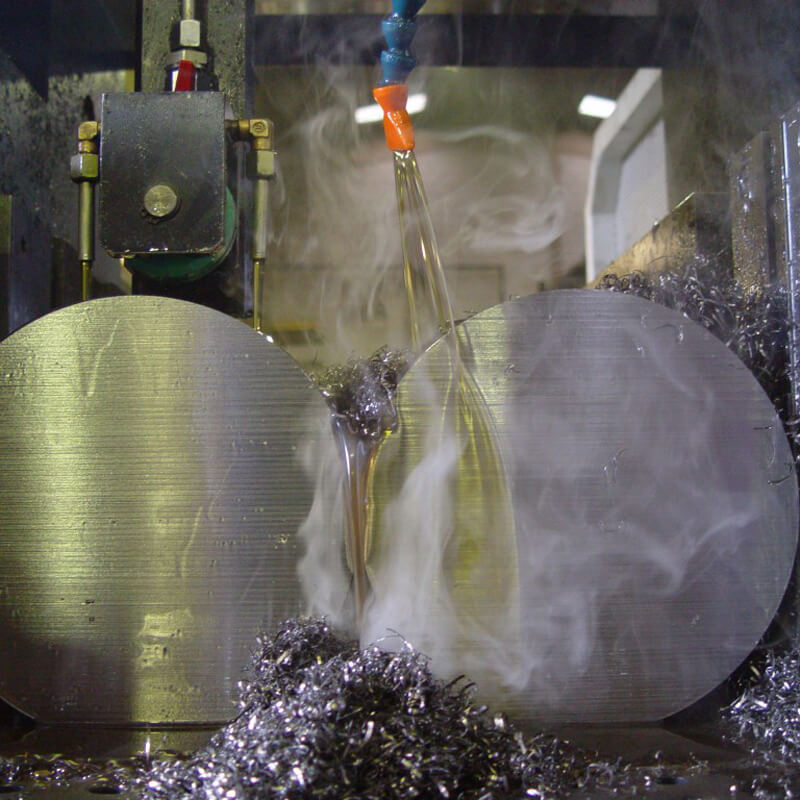

With its precision positive displacement pump and individually adjustable air and fluid volumes, the Serv-O-Spray™ spray lubrication system is the perfect Minimum Quantity Lubrication solution for any operation where controlled, intermittent fluid application is needed.

Actuating your Serv-O-Spray™ spray lubrication system is easy. Every time a compressed air signal is supplied from an actuation valve, the pump will deliver one quick shot of fluid out the nozzle tip along with a controlled amount of air. Air continues to flow from the nozzle tip until the air actuation valve is closed. Each time air is supplied in the spray lubrication system, the pump immediately fires another shot. The pumps can be cycled as often as needed, up to 150 times per minute.

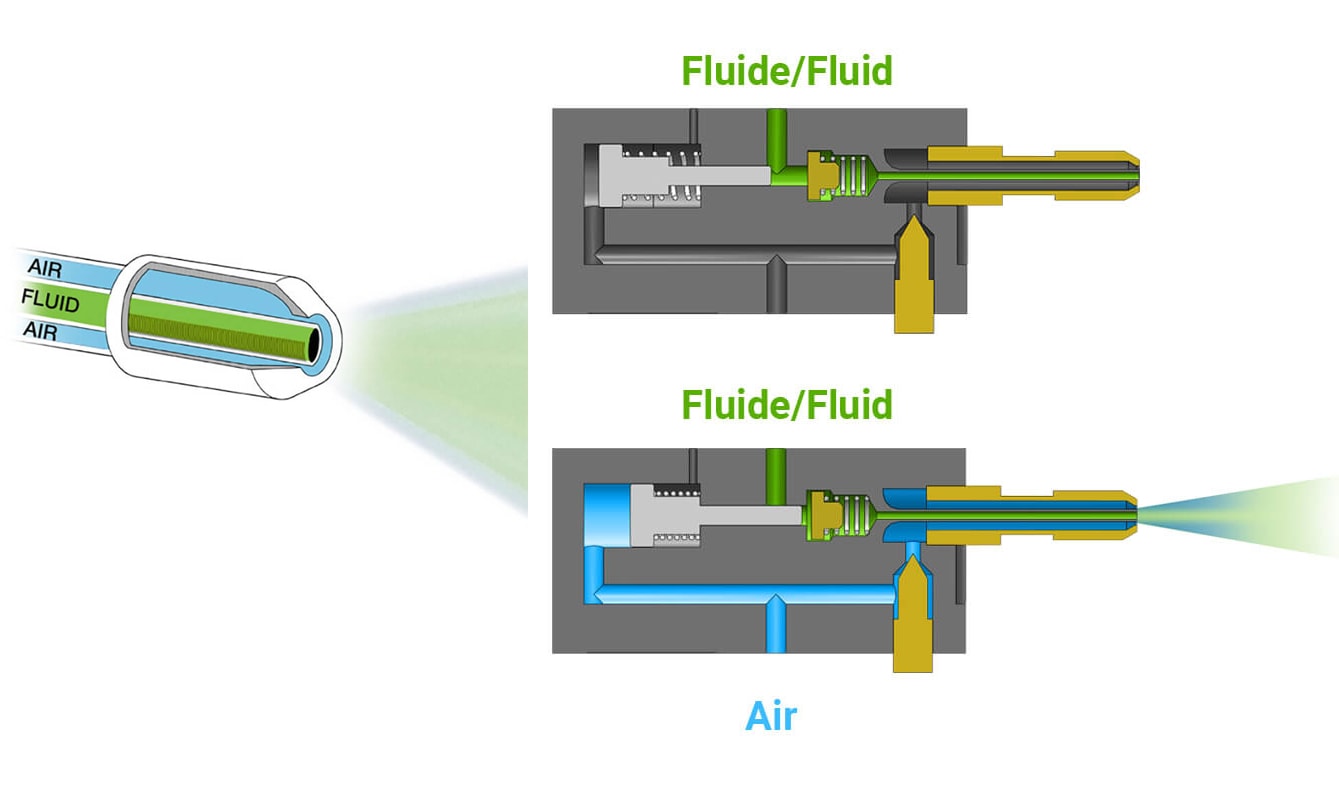

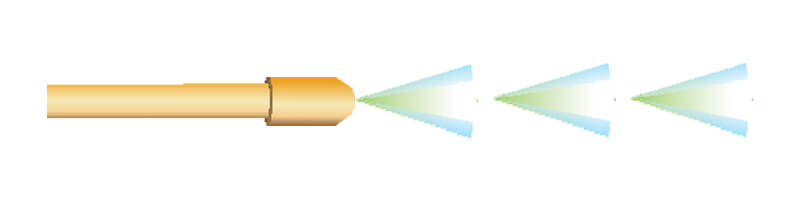

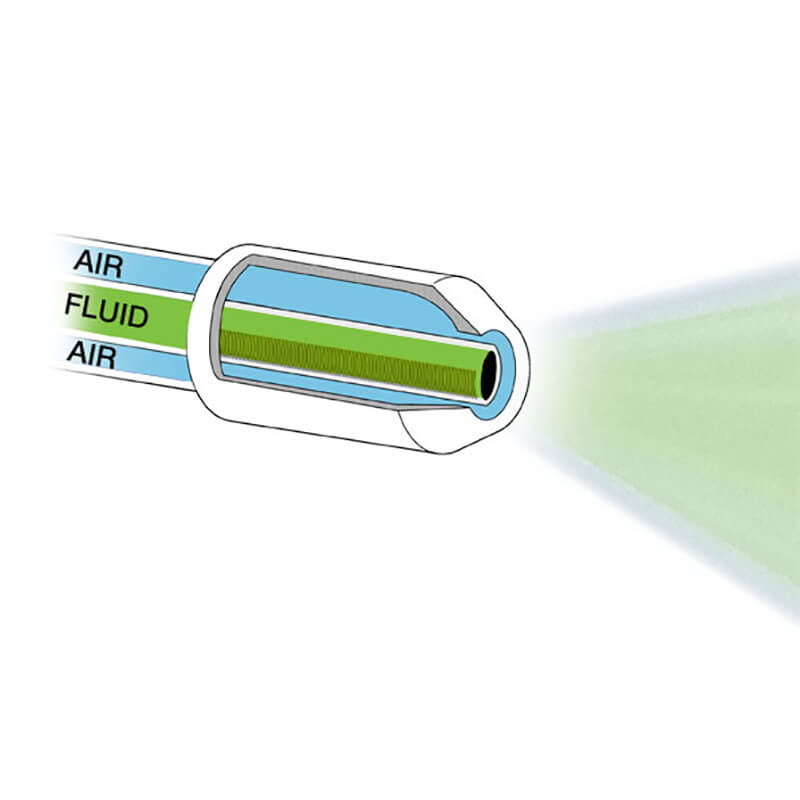

Our Co-Axial nozzles keep the air and fluid separate right up to the spray tip. This unique configuration can deliver fluid over long distances without the need for excessive amounts of air. Each time the pump strokes, a metered amount of fluid sprays out the nozzle tip, and is immediately atomized by the outer jacket of air. This feature on our spray lubrication systems delivers a balanced spray pattern at the point of application.

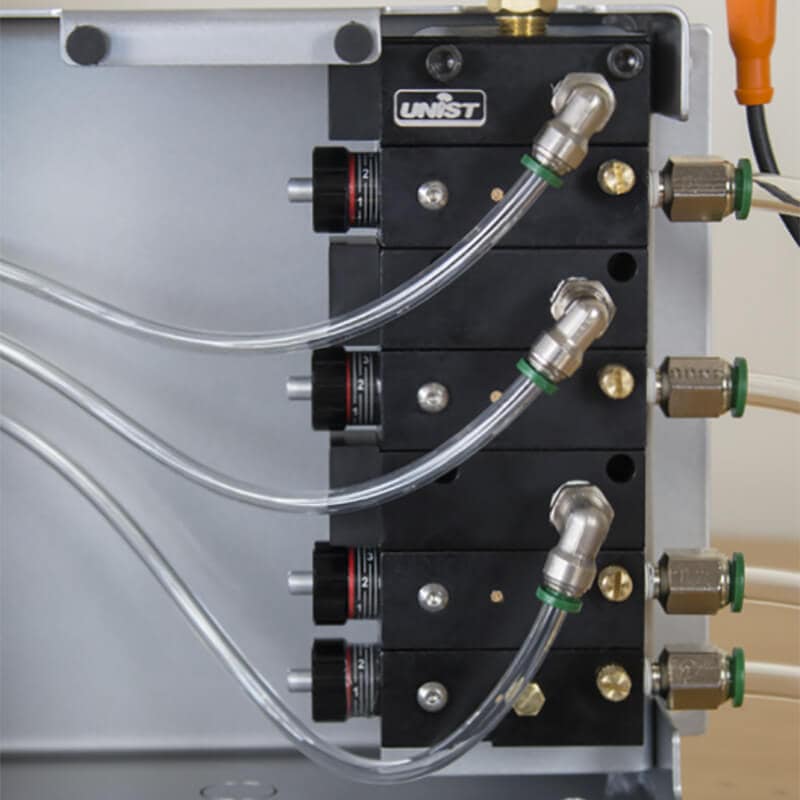

Serv-O-Spray can be configured for almost any application! Pumps can be actuated independently or in groups to spray multiple points with a single control valve.

The Serv-O-Spray™ was designed for precise control over the fluid application with separate fluid and air volume adjustments. This means that finding the sweet spot for your application is a breeze and once it’s set, the Serv-O-Spray™ spray lubrication system will deliver the same amount of fluid again and again.

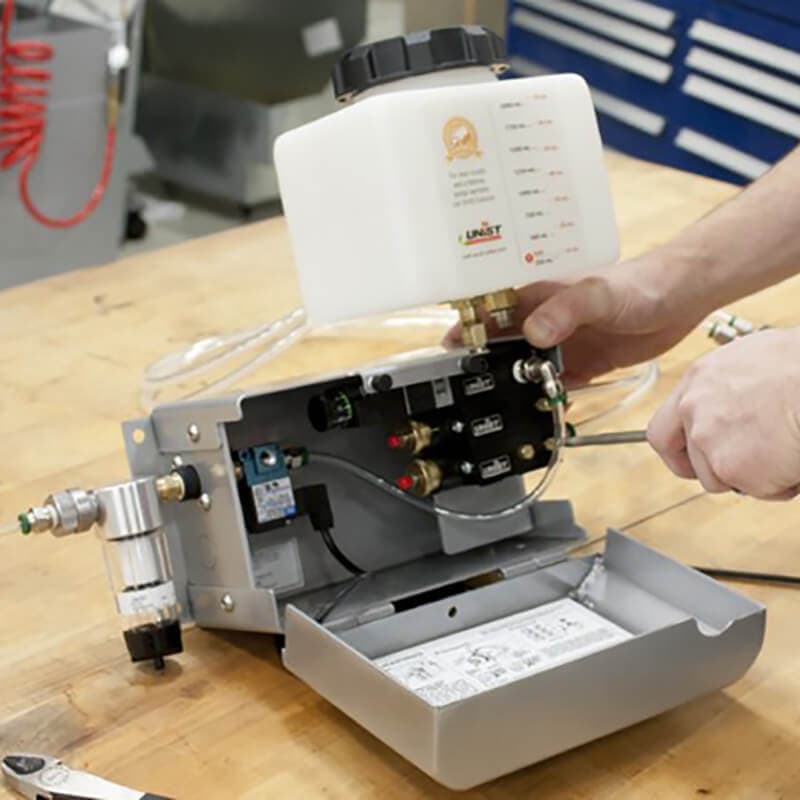

At Unist, the quality of our products is extremely important to all of us. That’s why each Serv-O-Spray™ undergoes an extensive 3-step testing process. We begin by fluid testing each metering pump individually to ensure proper output and function. Following that, we test the entire pump assembly before verifying the operation of the finished Serv-O-Spray™ assembly for a third time with Unist Coolube® lubricant.

| Outputs | Intermittent output-Delivers repeatable shots of fluid Multiple outputs - up to 16 pumps for 16 individual output options |

| Pumps(4 types available) | Standard 1 Drop (0.03 mL per stroke) Standard 3 Drop (0.10 mL per stroke) Multi-Viscosity(MV) 1 Drop (0.045 mL per stroke) Multi-Viscosity(MV) 2 Drop (0.10 mL per stroke) |

| Actuation | Control air input with manual valve, air pilot valve, or 3-way solenoid valve (110VAC or 24VDC) |

| Reservoirs | 16 oz. (473 ml), polyethylene 32 oz. (946 ml), polyethylene 64 oz. (1893 ml), polyethylene 64 oz. (1893 ml), polyethylene with low level |

For use with a low-flow air signal.

For actuation using an electrical signal from the machine.

Hands-free manual operation.

Multiple styles/lengths available