Automatic diamond band saw machine that cuts new materials with high quality and efficiency. Perfect for the high-quality cutting of advanced materials (hard-brittle materials) in the electronic parts and semiconductor markets.

Hard-brittle materials such as quartz glass, ceramics, carbon, carbon fiber reinforced plastics (CFRP), silicon carbide (SiC), silicon, sapphire, require high-quality cutting with high added value to meet market needs in the fields of electronic parts, semiconductors, optics, automobiles, and aerospace industry. By using a blade with diamond tips, kerf loss (material loss) is reduced, new materials can be cut with high quality, and the best cost performance is achieved.

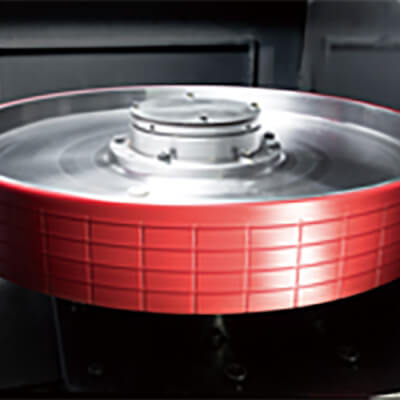

Because this specialized band saw uses a diamond blade, it is highly rigid and enables high-quality cutting of hard-brittle materials. Therefore, it helps improve processing efficiency by eliminating finish and other following processes. As an example, it enables ultra-thin high-quality cutting of quartz glass (a round plate with a ø300 mm, a thickness of 1 mm, a thickness accuracy of ±20 µm, a parallel flatness of 30 µm, and a surface roughness Rz = 23 µm), which is difficult to cut with a general band saw machine.

The band saw uses a blade featuring original metal chips that contain diamond abrasives. The blade ensures a high yield, and is ideal for cutting costly materials. A suitable blade can be selected according to workpiece material, cutting shape, and cutting conditions.

A compact design is achieved because the workpiece, together with the fixed pedestal, has been moved to the upper blade tip for cutting. In addition, safety has been improved by preventing the scattering of chips and cutting oil with a full cover, and fixing the door with an electromagnetic lock during operating.

In-flight dressing device (standard product)

A simple touch panel operation panel makes it easy to set processing conditions.

The large front door makes it easy to set up the workpiece.

The cutting motion moves the workpiece, making the machine more compact.

The complete cover prevents chips and cutting oil from scattering, improving the working environment.

| Model | DBSAW-500 | |||||||

|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | |||||||

| Cutting Capacity | Round (Diameter) | 19.7″ x 19.7″ | 500 × 500 mm | 19.7″ x 19.7″ 500 × 500 mm |

19.7″ x 19.7″ x 19.7″ 500 × 500 × 500 mm |

|||

| Rectangle (W x L x H) | 19.7″ x 19.7″ x 19.7″ | 500 × 500 × 500 mm | ||||||

| Saw Blade | Blade Size (W x L x T) | 4.9″ x 0,031″ x 0,11″ | 125 × 0,8 × 5410 mm | 4.9″ x 0,031″ x 0,11″ 125 × 0,8 × 5410 mm |

656-4921 ft/min 200 à 1500 m/min |

|||

| Blade Speed | 656-4921 ft/min | 200 à 1500 m/min | ||||||

| Motors | Saw Blade | 5 HP | 3.7 kW | 5 HP 3.7 kW |

3 HP 2.2 kW |

1/2 HP 0.4 kW |

2 HP 1.5 kW |

1 HP 0.75 kW |

| Hydraulic | 3 HP | 2.2 kW | ||||||

| Cutting Fluid | 1/2 HP | 0.4 kW | ||||||

| Cutting Servo | 2 HP | 1.5 kW | ||||||

| Positioning Servo | 1 HP | 0.75 kW | ||||||

| Separate Cutting Oil Tank Dimensions (Width x Depth x Height) | 27.6" × 78.8" × 84.4" | 700 × 2000 × 2145 mm | ||||||

| Separate Cutting Oil Tank Capacity | 79.3 gal | 300 l | ||||||

| Table Lower Limit Position | 38.5" | 977 mm | ||||||

| Table Elevating Stroke | 20.9" | 530 mm | ||||||

| Power Requirement | 11.7 kVA | |||||||

| Allowable Load on Machine | 661.4 lbs | 300 kg | ||||||

| Machine Weight | 11 023.11 lbs | 5000 kg | ||||||