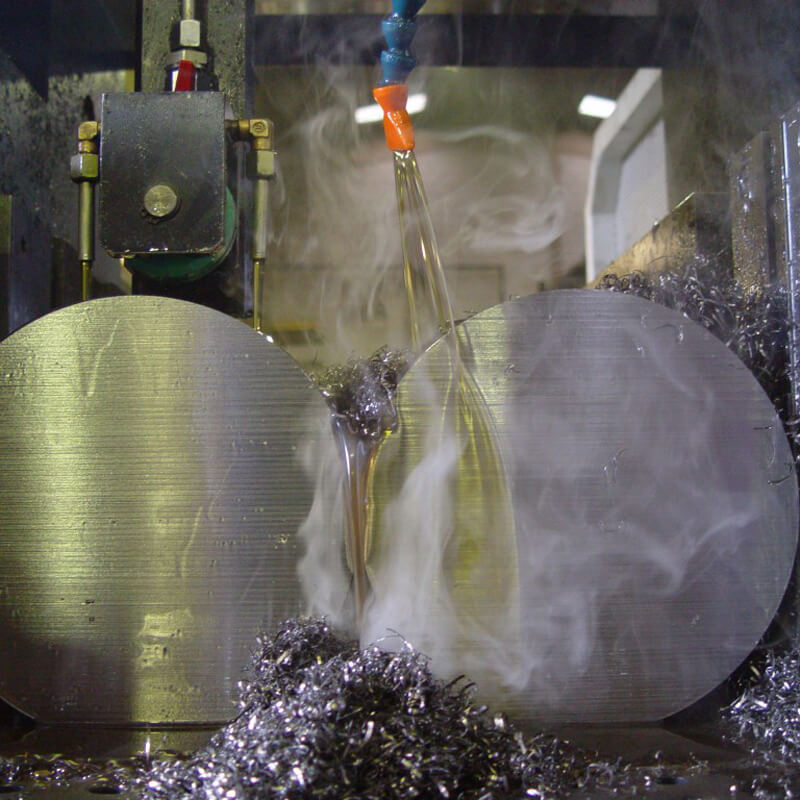

With its precision positive displacement pump and individually adjustable air and fluid volumes, the Coolubricator{tm} precision lubricant system is the perfect Minimum Quantity Lubrication solution for metal cutting.

With MQL, individual metal cutting applications each have their own "sweet spot" or precise amount of fluid necessary for optimum efficiency. Too little fluid, or too much fluid and tool life can suffer and fluid can be wasted. The Coolubricator™ gives you precise control over fluid output with separate fluid and air output adjustment. This means finding the sweet spot for your application is a breeze and once it's set, you can count on the Coolubricator™ to deliver the perfect amount of fluid again and again.

With its precision positive displacement pump and individually adjustable air and fluid volumes, the Coolubricator{tm} precision lubricant system is the perfect Minimum Quantity Lubrication solution for metal cutting.

With MQL, individual metal cutting applications each have their own "sweet spot" or precise amount of fluid necessary for optimum efficiency. Too little fluid, or too much fluid and tool life can suffer and fluid can be wasted. The Coolubricator™ gives you precise control over fluid output with separate fluid and air output adjustment. This means finding the sweet spot for your application is a breeze and once it's set, you can count on the Coolubricator™ to deliver the perfect amount of fluid again and again.

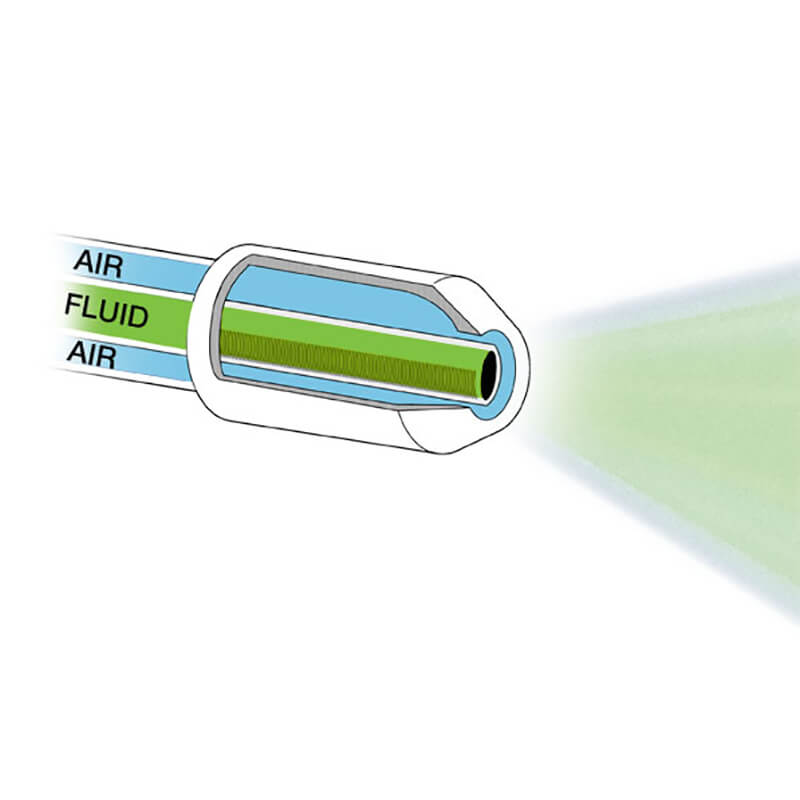

It is the key to delivering consistent atomization and fluid distribution over extended lengths of supply tubing. This is where the patented Unist Co-Axial Nozzle steps in. Fluid and air are kept separate until they are combined at the nozzle tip. This creates an evenly atomized spray and eliminates messy drips. Be sure to order your Coolubricator{tm} with Co-Axial hose and nozzle to maximize your lubricant delivery!

Maximize the benefits of MQL by filling your Coolubricator™ reservoir with Unist Coolube®. Coolube® is a 100% natural biodegradable lubricant derived from renewable vegetable products that is friendly to the environment and machinists. When applied properly, Coolube® is completely consumed in the machining process and the mess of traditional flood coolant is eliminated. As an added benefit, when a Coolubricator™ is used exclusively with Coolube®, Unist guarantees the pumps forever!

At Unist, the quality of our products is extremely important to all of us. That’s why each Coolubricator™ undergoes an extensive 3-step testing process. We begin by fluid testing each metering pump individually to ensure proper output and function. Following that, we test the entire pump assembly before verifying the operation of the finished Coolubricator™ assembly for a third time with Unist Coolube® lubricant.

| Outputs | Continuous Output – Pulse Generator = infinite cycling at an adjustable 5-200 pulse/min. Multiple outputs - up to 16 pumps for 16 individual output options |

| Pumps Options (4 types available) | Standard 1 Drop (0.03 mL per stroke) Standard 3 Drop (0.10 mL per stroke) Multi-Viscosity(MV) 1 Drop (0.045 mL per stroke) Multi-Viscosity(MV) 2 Drop (0.10 mL per stroke) |

| Actuation | Control air input with manual valve, air pilot valve, or 3-way solenoid valve (110VAC or 24VDC) |

| Réservoirs | 16 oz. (473 ml), polyethylene 32 oz. (946 ml), polyethylene 64 oz. (1893 ml), polyethylene 64 oz. (1893 ml), polyethylene with low level |

Mount securely to magnetic surfaces. Includes 4 strong, rare-earth magnets each capable of supporting 15lbs of weight for a total of 60 lbs, and mounting hardware.

Mount securely using 5/16" (7mm) dia. mounting flange holes and your own compatible hardware (no hardware supplied).

or use with a low-flow air signal.

For actuation using an electrical signal from the machine.

3-way slide valve for simple manual on/off control.

Hands-free manual operation.

(0.03 mL per stroke)

(0.10 mL per stroke)

(0.045 mL per stroke) Select this option to match your fluid delivery needs

(0.10 mL per stroke) Select this option to match your fluid delivery needs

1-3 outlet enclosure

4-6 outlet enclosure

7-11 outlet enclosure

12-16 outlet enclosure

Polyethylene

Polyethylene

Polyethylene with low level switch (Also available without a low level switch)

For use with a pressurized fluid supply.

Multiple styles/lengths available