| Code | |

|---|---|

| 50012 | LBC - Digital depth reader |

| 50020 | IR/RS - Automatic rotation inversion for manual tapping |

| 50035 | RHP - Automatic tapping system with standard spindle (includes one thread pitch) |

| 50038 | HGP_S - Additional standard spindle, special pitch |

| 50070 | HGP - Additional standard spindle, standard pitch |

| 50040 | ENG X - Automatic longitudinal movement by motorised feed box |

| 50080 | ENG Y - Automatic transversal movement by motorised feed box |

| 50089 | LDG 1 - Digital display for 1 axis (on control panel in articulated arm) |

| 50090 | LDG 2 - Digital display for 2 axes (on control panel in articulated arm) |

| 50100 | LDG 3 - Digital display for 3 axes (on control panel in articulated arm) |

| 50120 | PPZ - Collet holder with locking nut, set of collets, wrench, and case |

| 50130 | SC - 200mm column extension. |

| 50140 | ISO 30 - Extension for spindle ISO.30 |

| 50141 | ISO 40 - Extension for spindle ISO.40 |

| 50170 | SAH - Automatic tool holder for ISO taper |

| 50250 | ACNL - Rapid approach and retraction with pneumatic counterweight |

| 50260 | CI - Comprehensive cycle with encoder (only for BX models) |

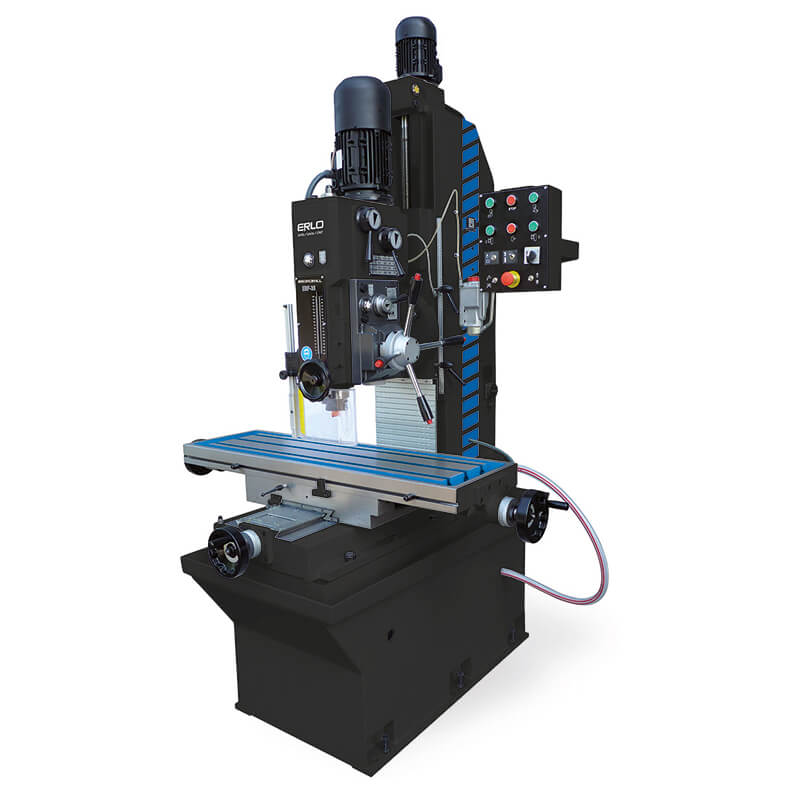

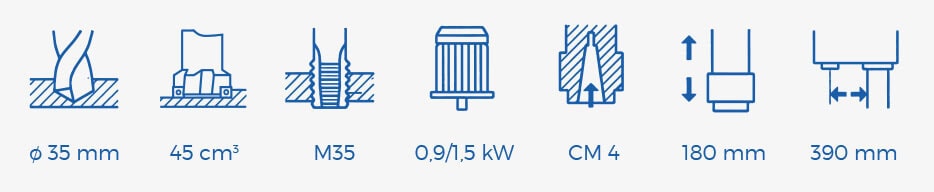

| Features | TF 35 | |

|---|---|---|

| Maximum steel drilling capacity 50/60 | 35 Ø mm | |

| Maximum steel tapping capacity 50/60 | M35 | |

| Morse cone | 4 Nr. | |

| Maximum spindle travel (drilling depth) | 180 mm | |

| Main motor power | 0,9/1,5 kw | |

| Transmission | Gears | |

| Number of speeds | 16 | |

| Speed range with motor at 1500 rpm 50Hz 3HP | 94 - 135 - 189 - 207 - 271 - 303 - 347 - 416 - 497 - 606 - 695 - 760 - 995 - 1112 - 1520 - 2225 rpm | |

| Speed range with variator at 1500 rpm 50Hz 3HP | A) 152 - 605 B) 223 - 890 C) 559 - 2236 D) 818 - 3272 rpm |

|

| Feed | Automatic with electromagnetic clutch | |

| Number of automatic feeds | 3 | |

| Automatic feed range | 0,8 - 0,18 - 0,24 | |

| Longitudinal table movement (X) | 700 mm | |

| Transversal table movement (Y) | 360 mm | |

| Distance from the spindle centre to the face of the column | 390 mm | |

| Net weight | 910 kg | |

| Gross weight with packaging | 1400 kg | |

| Packaging dimensions (length x width x height) | 2690 x 1780 x 1780 mm | |