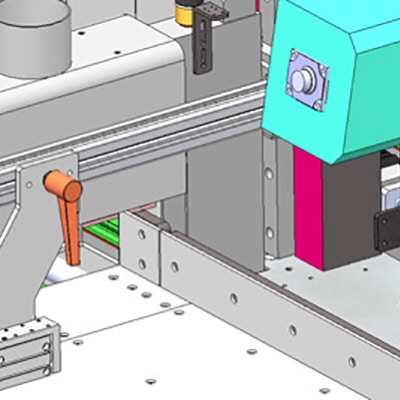

Optional: 90 ° angular head with sawblade.

Optional tool magazine for optional tool change automatically.

Optional: Auto measuring system

| Model | J-CNC 18 MDS |

|---|---|

| Applicable Machine | J-455 |

| Tool Magazine Capacity | 8 pcs |

| Automatic Drive System | Ball screw (Servo motor drive) |

| Cutting Capacity (H x W) | 120 x 120 , 100 x 200 , 20 x 280 mm |

| Cutting Length Display Set Up | Touch-sensing screen |

| Hydraulic feed motor | 1 HP |

| Stroke | 1.25 M |

| Touch-sensing screen | 12” |

| Saw blade size | 18” x 1” bore |

| Air pressure | 6 kgs / cm2 |

| X-Axis Stroke | 1,100 mm |

| Y-Axis Stroke | 325 mm |

| Z-Axis Stroke | 330 mm |

| X1 Servomotor | 850 W |

| X2 Servomotor | 850 W |

| Y-Axis Servomotor | 750 W |

| Z-Axis Servomotor | 750 W |

| Spindle Speed | 12,000 R.P.M. |

| Spindle Taper | NBT30 |

| Spindle Motor | 3.8 kw |

| Saw Motor | 7.5 HP |

| CNC Controller | SYNTEC |

| Rapid feed rate (X / Y / Z) | X:40 M/min ; Y:25 M/min ; Z:25 M/min |

| Machine Dimensions(L x W x H) | 3,500 x 2,120 x 2,650 mm |

| Packing Dimensions (L x M x H) | 3,600 x 2,220 x 2,750 mm |

| Net / Gross Weight | 2,600 / 2,780 kgs |