These days, “going green” is a concern for many manufacturers and implementing Minimum Quantity Lubrication (MQL) with Unist Coolube® is an easy step in that direction. MQL is the process of applying minute amounts of high-quality lubricant directly to the cutting tool/work piece interface instead of using traditional flood coolants. MQL minimizes your environmental impact by significantly reducing fluid usage and eliminating the need for coolant treatment and disposal. These benefits are multiplied further when using 100% biodegradable Coolube® metal cutting lubricants which are formulated from renewable plant-based oils. When considering these facts along with the performance benefits of Coolube® and MQL, it becomes obvious that this is the future of metal cutting fluid!

Using the right metal cutting lubricant is very important in MQL applications. The perfect lubricant will adhere to the surface of the tool and provide a thin, low friction barrier between the cutting tool and work piece. Studies have shown that Coolube® metal cutting fluid has superior properties which make it an ideal lubricant. Coolube’s® polar properties create a strong consistent bond between Coolube® and metallic surfaces. This creates an even, strong, and durable layer of lubrication. Coolube® reduces friction 50% better than typical mineral oils preventing heat buildup and resulting in longer tool life and a superior cut finish.

The installation of the Unist system took a few hours, but afterward, the money savings and the cleanliness of the work area were quickly noticed. A plus for all saws and companies that want cleaner working air and a healthier environment for their workers. The return on investment is excellent.

Thanks to very precise micropumps, the lubricant dosage is perfectly controlled. The system uses only a tiny amount of milliliters a day rather than liters of fluids.

Increase the air quality of the work environment by eliminating odor problems caused by bacterias in soluble oils. Reduce your workload and stop removing abrasives on the grounds. Thanks to the minimum quantity lubrication technique, there is less wear and the condition of the surfaces are improved.

With Unist, you will have clean, non-slippery floors, which will reduce the risk of falls and injuries.

You will contribute to a significant reduction of polluting discharges into the environment;

Increase the life of your tools from 20% to 100%; you will reduce or even eliminate the thermal shocks that they undergo;

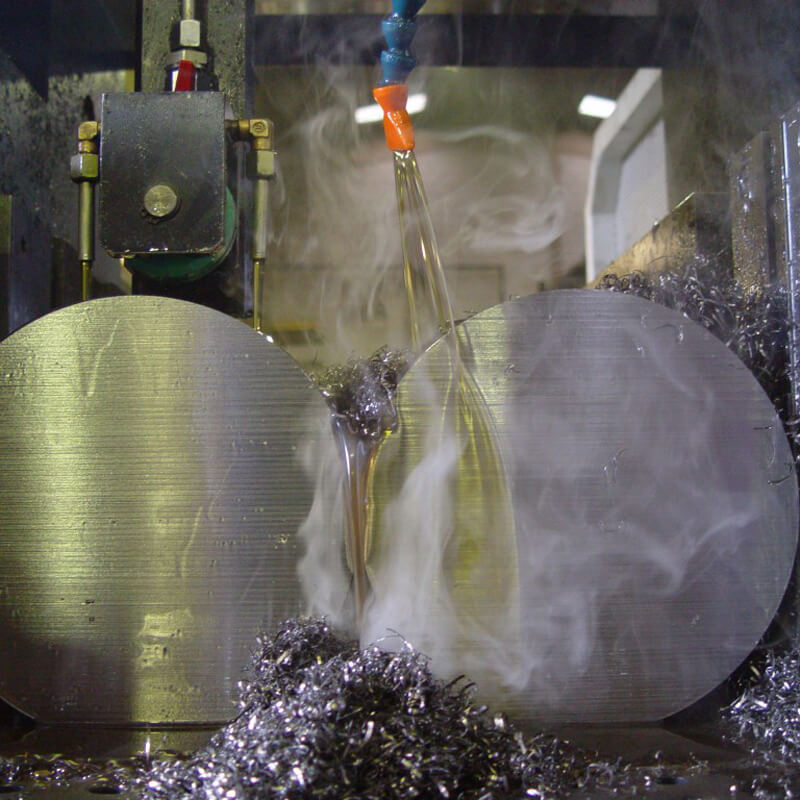

You will have dry and easy to dispose of chips;

| Coolube | Ferrous | Non-ferrous | Aluminium | Odor | Appearance | Solubility | Flash point | Viscosity | Hazardous (SIMDUT/OSHA) |

|---|---|---|---|---|---|---|---|---|---|

| 2210 | Yes | Yes | Yes | mild | clear | Insoluble | >400°F (200°C) | 104°F (40°C), 16 cSt | No |

| 2210XP | Yes | Yes | Yes | Characteristic | yellow | Insoluble | >400°F (200°C) | 16 cSt [82 SUS] | No |

| 2210AL | No | No | Yes | mild | clear | Insoluble | >199°F (93°C) | 104°F (40°C) | No |