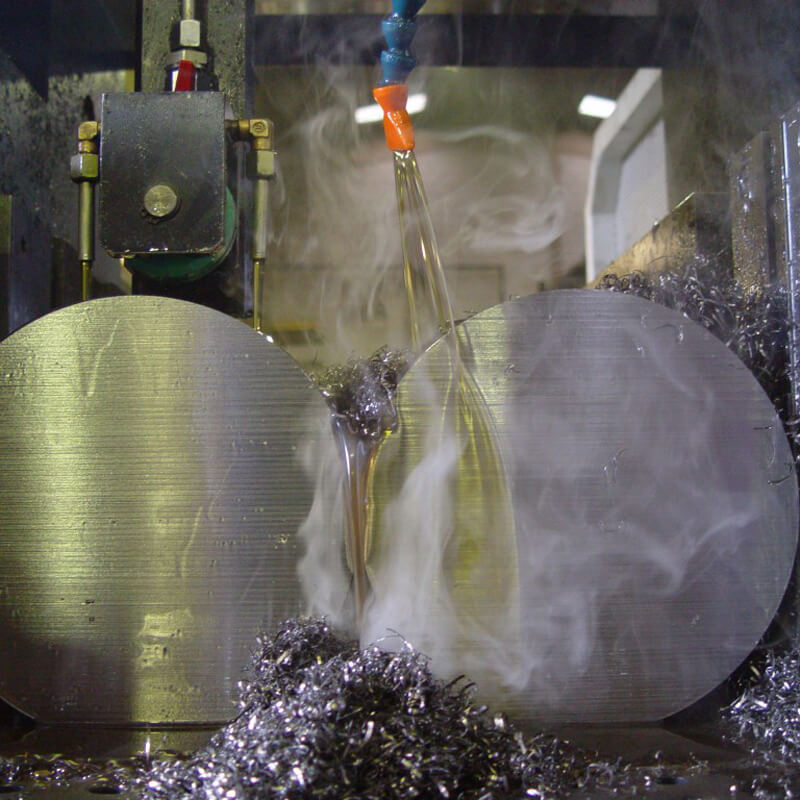

Globe Condacut 105 is a premium blend of highly refined mineral oil, fatty esters and extreme pressure additives. Globe Condacut 105 is designed for use in general purpose light to medium operations. Globe Condacut 105 is suitable for all materials.

Globe Condacut DP 615 is a premium blend cutting oil, extreme pressure lubricant, chlorine-free. Globe Condacut DP 615 is suitable for heavy duty machining.

Globe Condacut DP 720 is a low viscosity neat oil made froma premium blend of highly refined mineral oil, fatty esters and extreme pressure additives, and is designed for general purpose use in medium to heavy duty operations.