Sections thermal coping

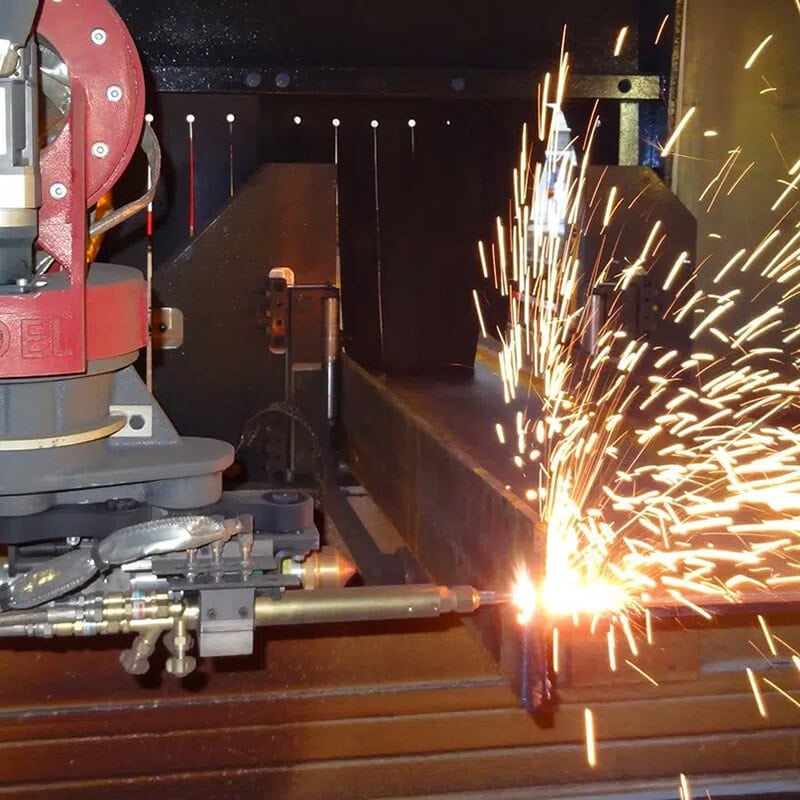

Automatic CNC thermal coping robot for sections. Flex is the latest process in automatic CNC controlled thermal coping. This brand new model from Ficep is capable of processing steel profiles at top speeds and at the highest quality standards. Plasma and oxy-fuel units can be used on this line due to its innovative design. This model is the industries benchmark when it comes to thermal processing of structural steel shapes.

This unique torch is the latest patented process in thermal coping robots. Its special wrist has been designed to process profiles on four sides with both oxy-fuel and plasma.

Automatic clamping devices guarantee perfect position of the profile.

The new laser scanner process is used to probe the profiles geometry to compensate for mill tolerance deviations. This enables reliable torch ignitions and accurate locations of the programmed thermal processes.

This brand new process allows the machine to automatically switch between plasma and oxy-fuel in seconds.

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

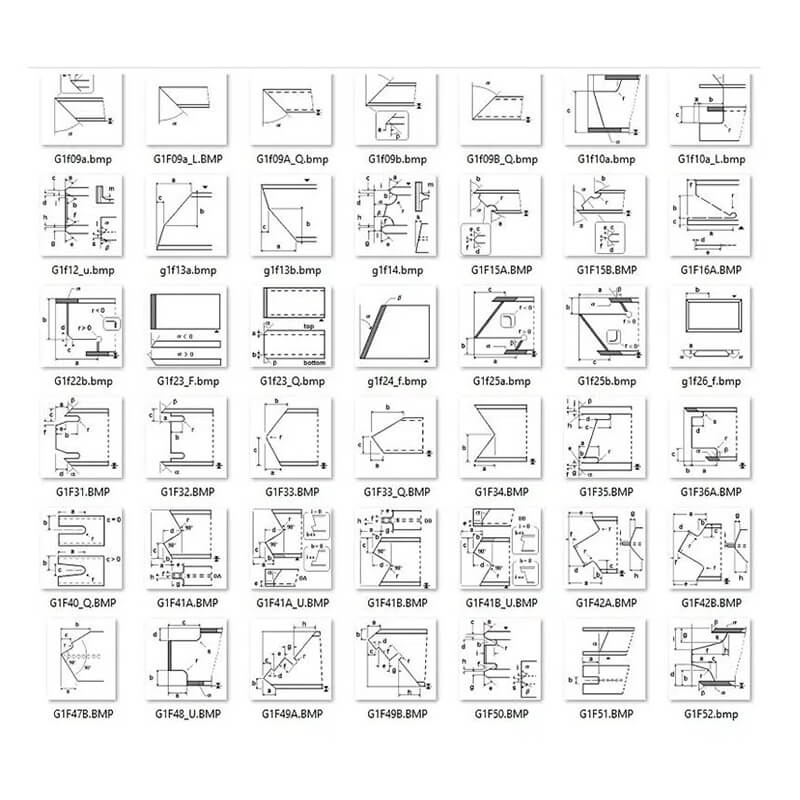

This machine is equipped with a CNC library of macros to generate the most efficient cutting routines.

Hypertherm True Hole process is available on this model.

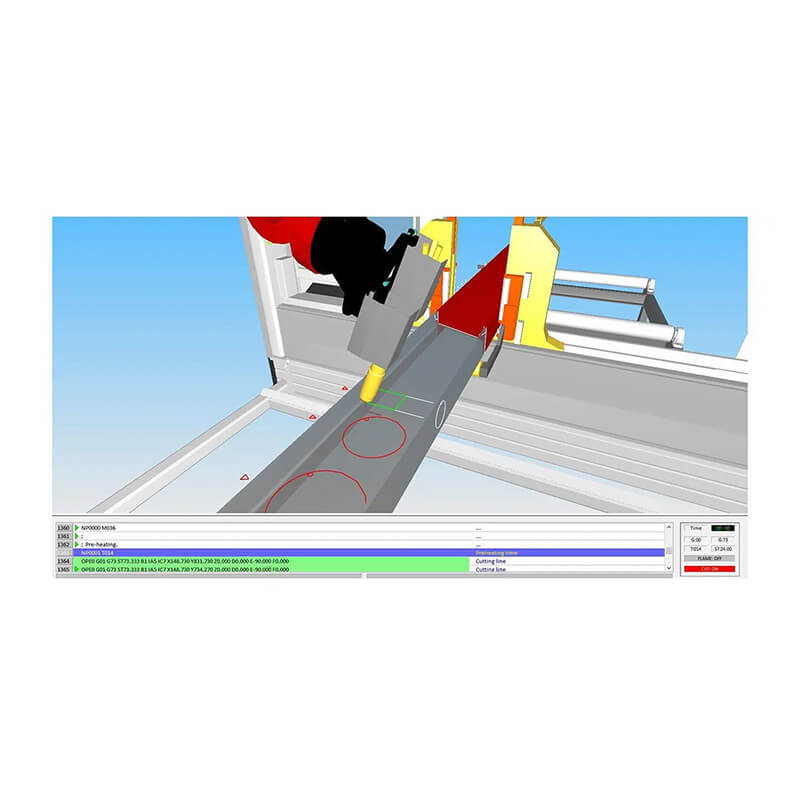

Graphical 3D simulator shows the virtual process to be managed.

When combined with drilling lines, there is no need to add a further CNC unit as the entire system is controlled by a single CNC.

All our systems are supplied in accordance with the highest safety standards and regulations.

| Flex | Section size [min.mm] | Section size [max.mm] | Oxy-fuel-fuel torch [no.] | Plasma torch [no.] |

|---|---|---|---|---|

| 1201FRC | 50 x 10 | 610 x 460 | 610 x 460 | 3800 |