Angles drilling and cutting

The close tolerance requirements and engineering specifications required for many applications can easily be addressed with the new RAPID high-speed angle drilling lines. The exceptional productivity is achieved with spindle sub-axis positioning that is capable of processing offset holes in both legs simultaneously. This unique design makes the Rapid an economical and productive solution even on the largest of angles.

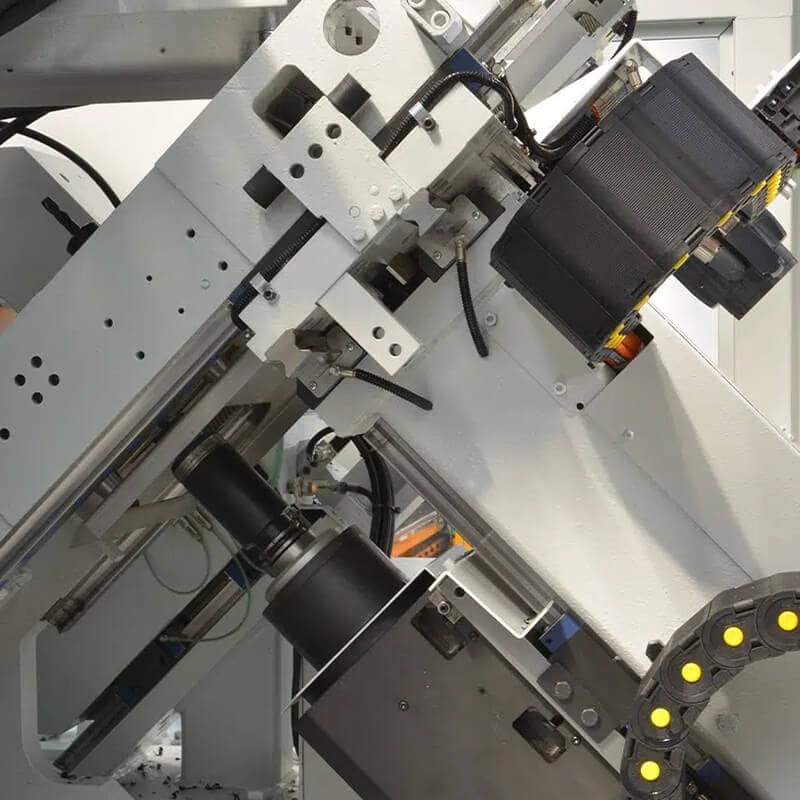

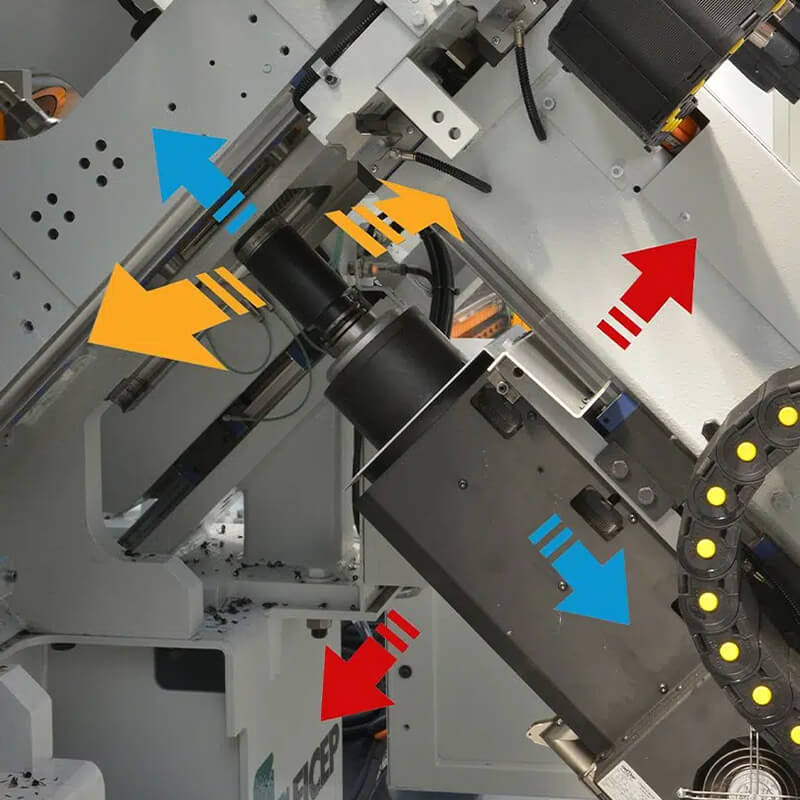

High speed drilling units equipped with powerful direct drive spindles and positioning with servo drives through a rack and pinion system.

The drill units are equipped with a 3 or 6 position automatic tool-changer system for quick tool replacement.

Each spindle is equipped with a 200mm (7-7/8”) sub-axis stroke in the X axis to perform milling operations and slotting in any direction.

A single cut shear with a special hold-down systems to achieve the utmost in shearing precision. All shear blades are manufactured internally to guarantee the best quality and exceptional tool life.

One disc saw for 90° angle cutting is available as standard as an alternative to the shearing unit.

Marking of pieces is possible with a fully programmable marking press or the traditional cartridge style system.

A special tool to allow milling operations on the angles heel, complete with relevant tool-holder in special configuration.

A high speed carriage with a pincher system is for fast and accurate angle positioning through the working units.

Thanks to a laser device positioned on the infeed conveyor it is possible to exactly measure the material stock length prior to processing.

A unique material loading system automatically lowers the next required stock length material onto the infeed conveyor.

All our lines can be configured with infeed and outfeed cross transfer tables to allow automatic loading/unloading of stock lengths and finished parts.

| RAPID | Angle size (410 N/mm²) [min. mm] | Angle size (410 N/mm²) [max. mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max.mm] | Spindle power [kW] | Spindle speed [max.RPM] | Spindle sub-axis stroke [mm] | Cutting unit |

|---|---|---|---|---|---|---|---|---|---|

| RAPID 16T | 40 x 40 x 4 | 160 x 160 x 20 | 2 | 3 (6) | 40 | 11 (15) | 3500 | 200 | Shear (circular saw) |

| RAPID 20T | 40 x 40 x 4 | 200 x 200 x 25 | 2 | 3 (6) | 40 | 11 (15) | 3500 | 200 | Circular saw (shear) |

| RAPID 25T | 60 x 60 x 6 | 250 x 250 x 40 | 2 | 3 (6) | 40 | 19 (27) | 3500 | 200 | (Circular saw - shear) |

| RAPID 35T | 60 x 60 x 6 | 350 x 350 x 40 | 2 | 3 (6) | 40 | 19 (27) | 3500 | 200 | (Circular saw) |