Plate drilling and thermal cutting

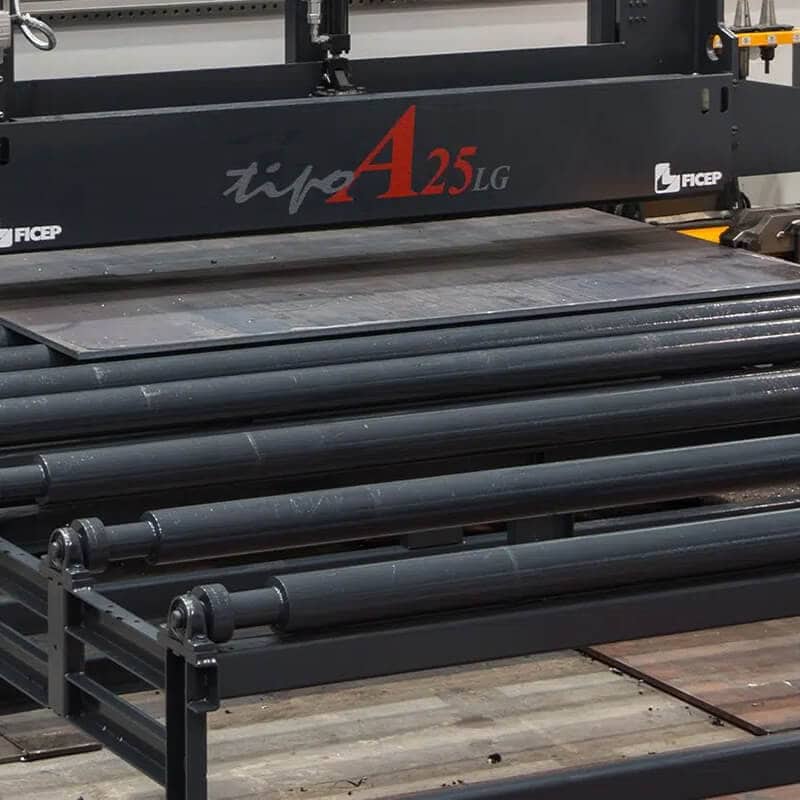

Automatic CNC drilling & thermal cutting systems for heavy plates. TIPO A work centers can automatically generate in one cycle the typical operations required in the steel fabrication industry. The operations of drilling, milling, pointing, tapping, marking and thermal cutting on large stock plates. The versatility of the Tipo A is endorsed by steel fabricators worldwide.

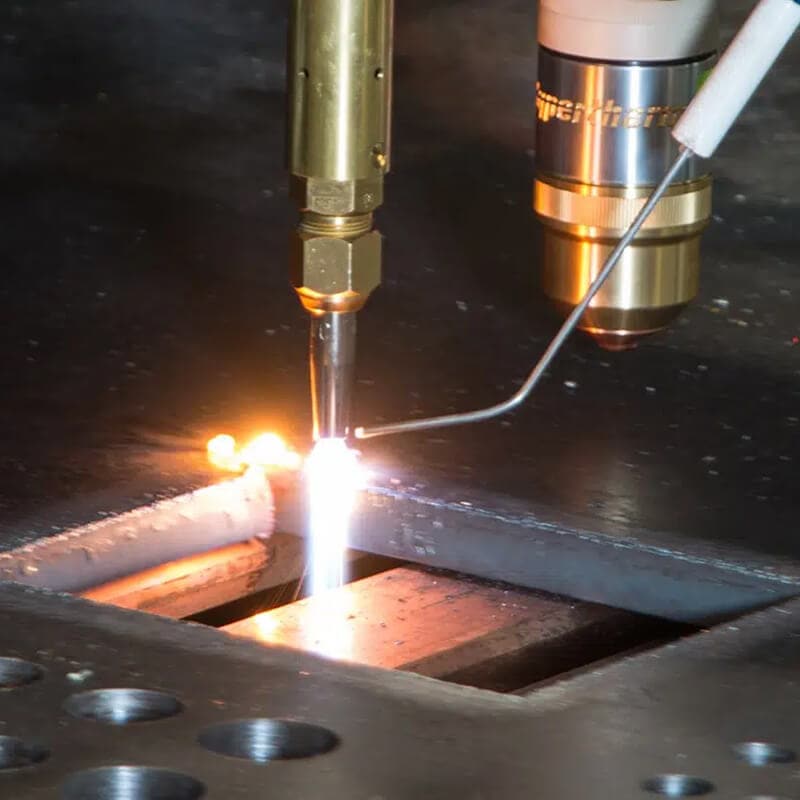

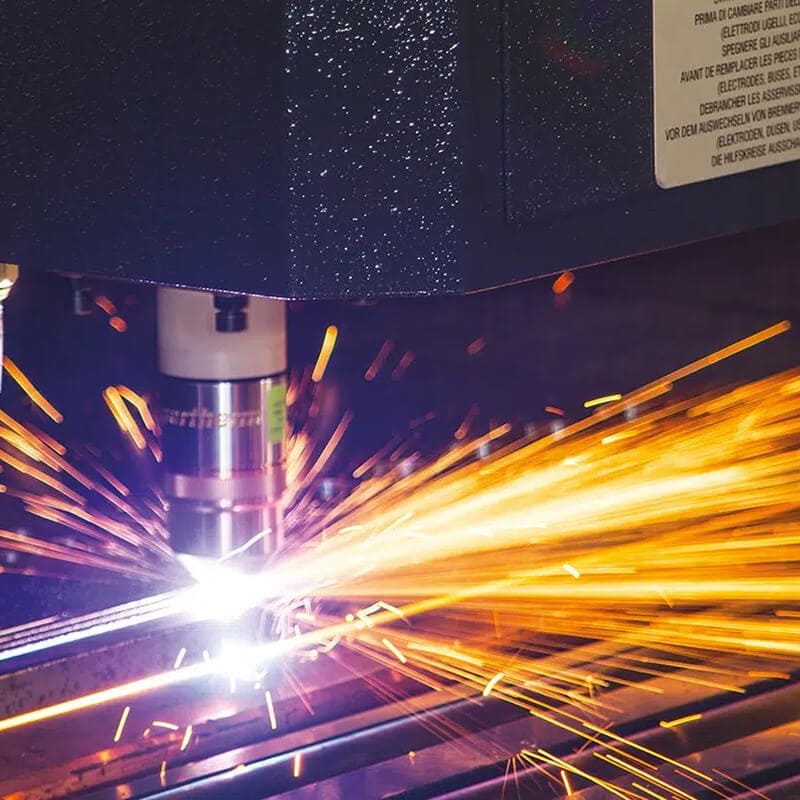

The high performance drill spindle is designed to perform diverse comprehensive operations.

The automatic tool change system is controlled by the CNC control and is equipped with 6 or 12 positions.

The system can be equipped with an additional drill spindle and tool-changer to increase the productivity.

TIPO A is supplied with one oxy-fuel torch, and the possibility to add a second torch.

Hypertherm XPR170, XPR 300 or HPR400XD power source can be supplied with one or two high-definition plasma torches.

Depending on the model, plates are positioned by a carriage with linear pincher or with lateral double grippers.

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements

The infeed and outfeed conveyors can be extended in order to accommodate longer stock plates. The conveyors are pre-arranged to receive cross transfer tables for loading and unloading of plates.

A special trap door can be supplied to unload finished parts with a max. size of 500x500mm.

| TIPO A | Plate size [max. mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max. mm] | Drilling thickness [max. mm] | Spindle power [kW] | Spindle speed [max. RPM] | Plasma torches [max. no.] | Oxy-fuel torches [max. no.] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| TIPO A25LG | 2540 x 6000 | 2 | 6 (12) | 40 (50) | 100 | 33 | 3000 | 2 | 2 | 15000 |