Roller Feed Angles Punching and Shearing

The “XP R” series in the FICEP product line have been created for small and medium size steel fabrication firms. These systems provide great flexibility and amazing ease of use so they are extremely versatile in addressing diverse applications. The “XP R” product range is available with a comprehensive assortment of options so the systems can be configured to address user’s unique applications.

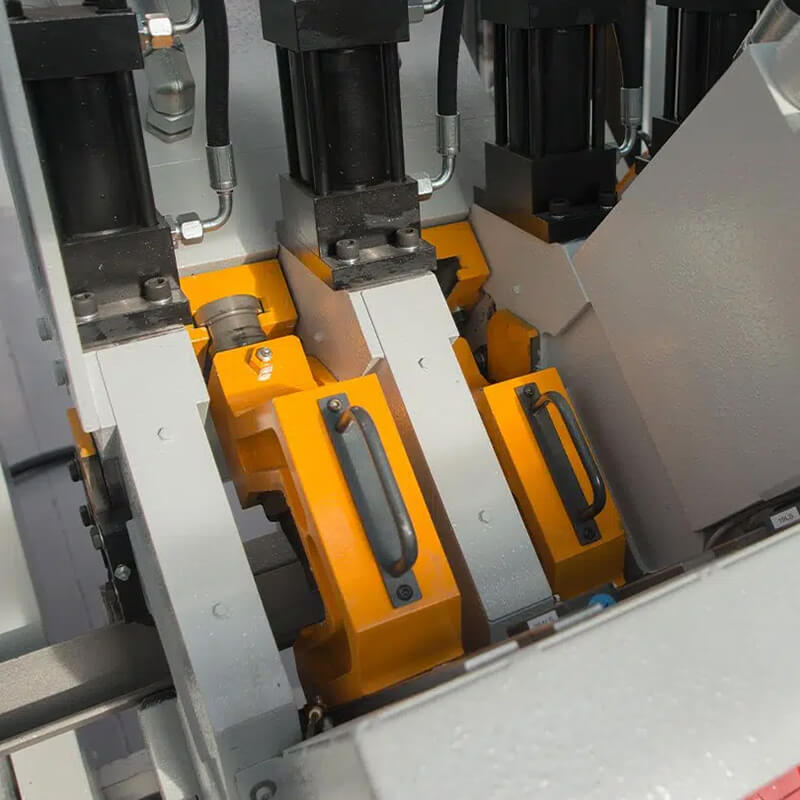

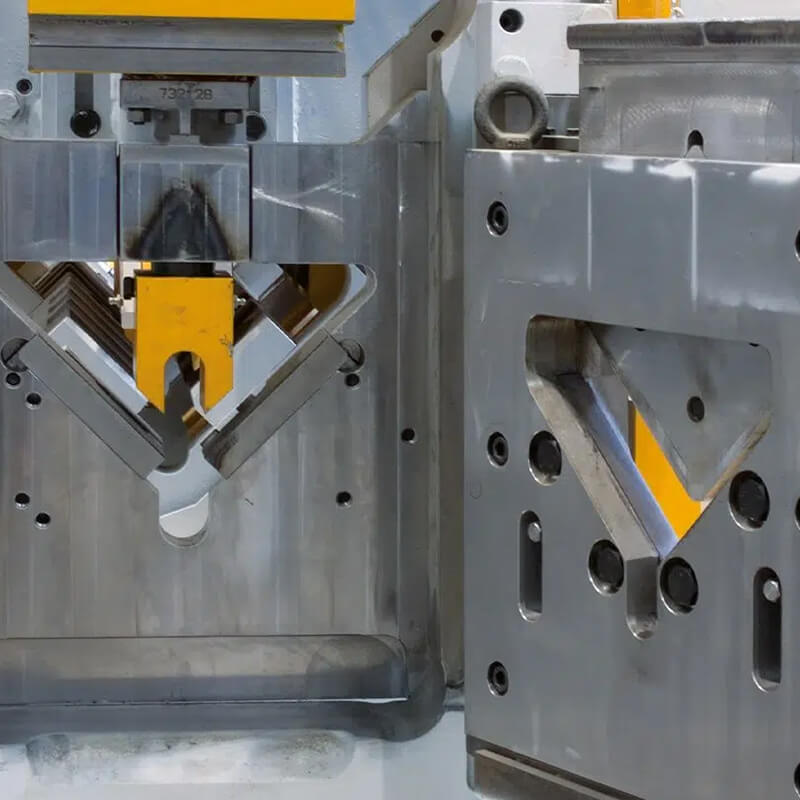

The angle lines of XP R series are equipped with one, two or three punching units per angle leg. Each press incorporates an easily removable self-contained tool holder for quick punch and die changes.

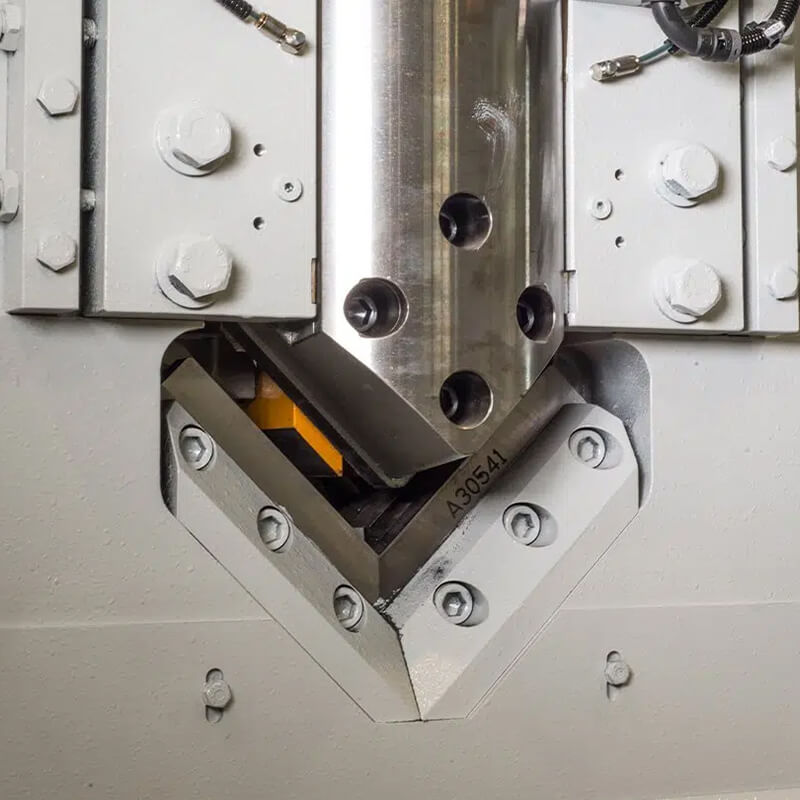

Single cut or double cut shears are available with a special hold-down systems to achieve the utmost in shearing precision. All shear blades are manufactured internally to guarantee the best quality and exceptional tool life.

Marking of pieces is achieved with a programmable marking unit.

Our XP R lines can be equipped as an option for flat bar processing.

A versatile shearing system with quick-change tooling can be furnished to process angles, flats and channels.

An optional versa press can be furnished which can accept tooling for marking, special punching applications and notching.

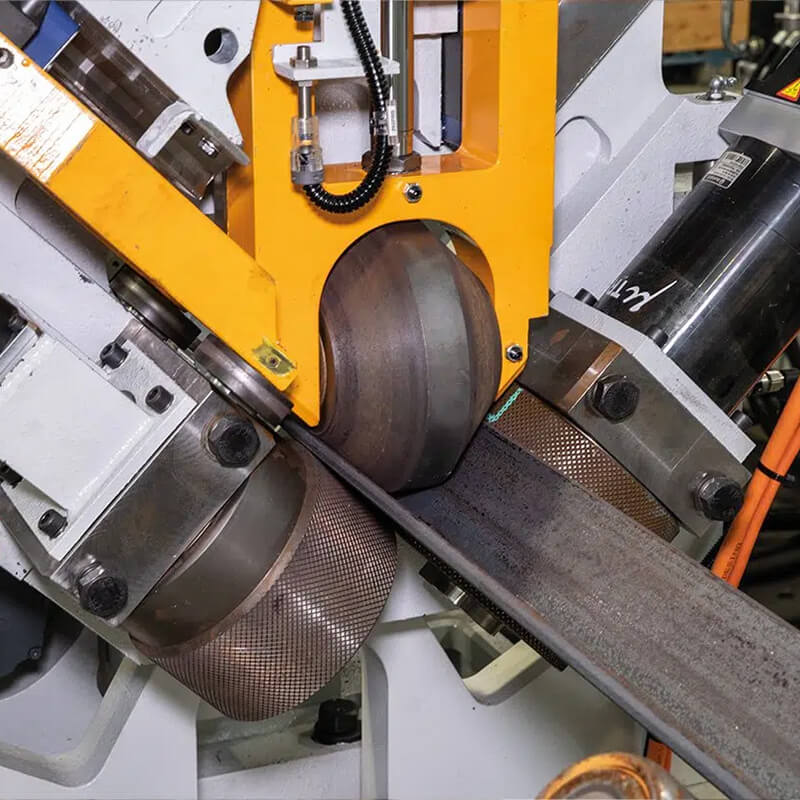

The CNC controlled positioning and measuring system consists of two internal roller feed drives and measuring rolls to accurately locate the material to the programmed position.

The infeed and outfeed conveyors are furnished with idler rolls.

A unique material loading system automatically lowers the next required stock length material onto the infeed conveyor.

| XP R | Angle size (410 N/mm2) [min.mm] | Angle size (410 N/mm2) [max.mm] | Diameter per flange [no.] | Punching force [kN] | Punching diameter [max.mm] | Shearing force [kN] |

|---|---|---|---|---|---|---|

| XP10R2 | 30 x 30 x 3 | 100 x 100 x 13 | 1 | 650 | 32 | 1800 |

| XP10R4 | 30 x 30 x 3 | 100 x 100 x 13 | 2 | 650 | 32 | 1800 |

| XP12R4 | 30 x 30 x 3 | 120 x 120 x 13 | 2 | 650 | 32 | 1800 |

| XP12R6 | 30 x 30 x 3 | 120 x 120 x 13 | 3 | 650 | 32 | 1800 |

| XP16R2 | 30 x 30 x 3 | 160 x 160 x 19 | 1 | 800 | 32 | 2200 |

| XP16R4 | 30 x 30 x 3 | 160 x 160 x 19 | 2 | 800 | 32 | 2200 |

| XP16R6 | 30 x 30 x 3 | 160 x 160 x 19 | 3 | 800 | 32 | 2200 |