Plate edge milling

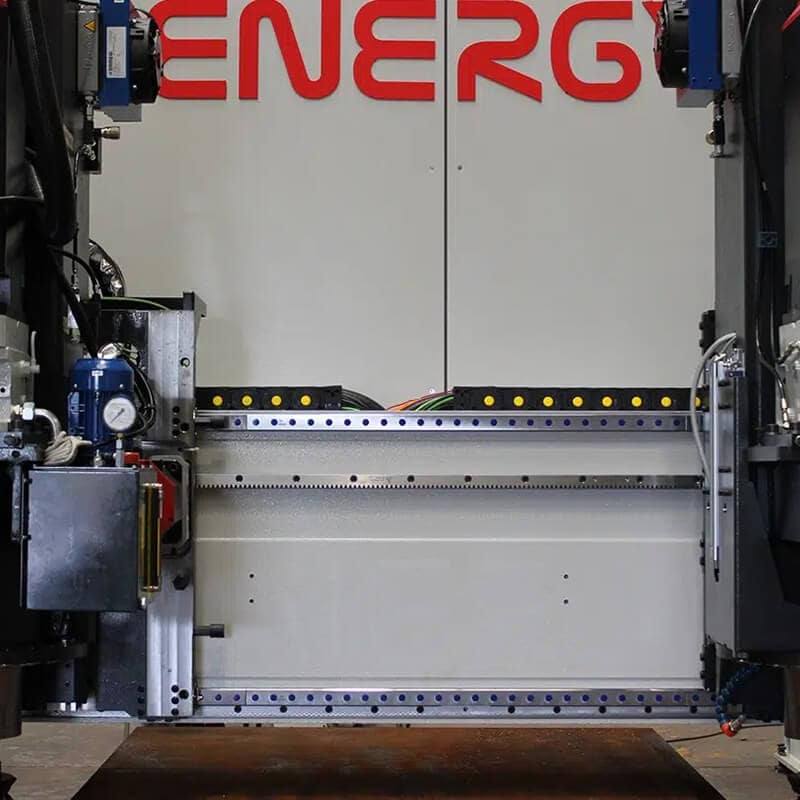

CNC gantry working center for plate edge milling. The Energy is the new CNC working center designed and manufactured by FICEP for plate edge milling, drilling, tapping and marking, specially dedicated to the wind sector (towers, TP, foundations, etc.). An advanced and powerful technological solution, studied to guarantee high productivity, processing versatility and great performance within the high quality standards required by the different application fields regulations.

The power generated by the 70/123 kW (94/165 HP) spindles drives the milling tools at a very high torque. This power, in combination with the performances of the tools with HSK-B160 adapters, offers an excellent chip removal for fast, accurate and efficient processing.

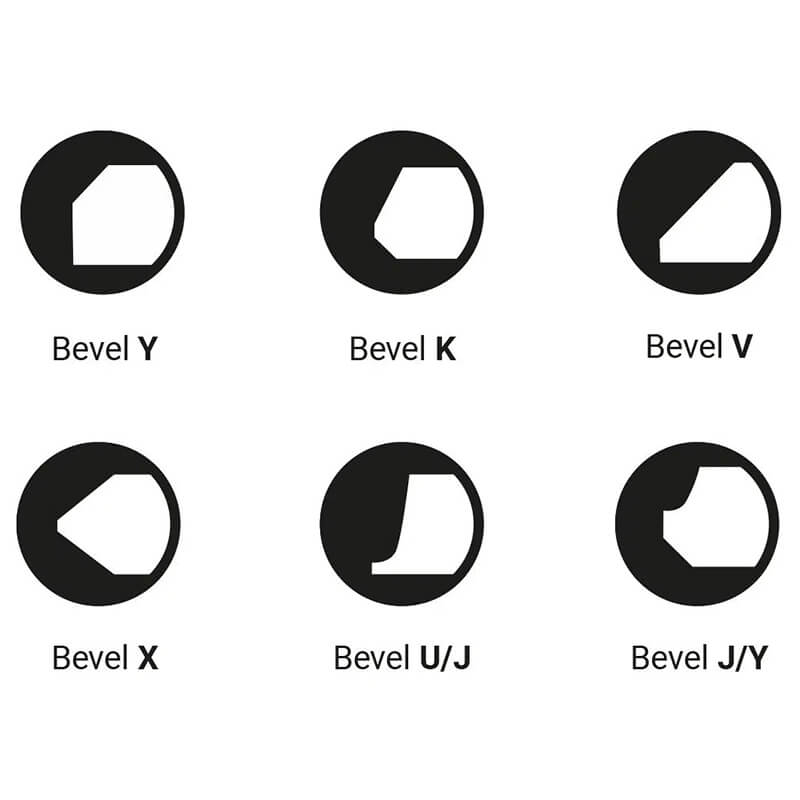

The Energy carries out all the bevels required by the different welding technologies: Y, K, V, X, U/J, J/Y. It is possible to design customized milling tools with specific geometries according to the customer needs.

Accurate Edge Preparation is the new FICEP process which allows the ENERGY to be so performing. High processing speed and extremely complex bevels with no modification to the material properties and substantial beveling quality, are just a few of the characteristics that makes the A.E.P. process unique.

The spindle engineering and power guarantees a very high chip removal rate. The high working and positioning speed, that reaches up to 30 mt/min (98 FPM) on the X axis, the quick tool change, the wide working table and the ability to process all four edges of the plate in one clamping makes the ENERGY and extremely productive solution.

FICEP fully controls the manufacturing process thus ensuring the use of the best raw material and components that guarantees long term satisfaction.

The spindles are equipped with an extremely precise probing device to locate all the required plate surfaces. The tool changer system, mounted on board of the spindle, automates and expedites the tool replacement phase in order to quickly start the next process.

| Energy | Plate size [max.mm] | Plate thickness [max.mm] | Independent milling heads [no.] | Milling tools per head [no.] | Milling tool diameter [max. mm] | Spindle power [kW] | Spindle speed [max.RPM] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|

| 3502 GDX DD | 3500 x to 60000 | 160 / 250 | 2 | 5 *6 tools per head are available upon request* |

360 | 70/123 | 1500/1000 | 28000 |

| 5002 GDX DD | 5000 x to 60000 | 160 / 250 | 2 | 5 *6 tools per head are available upon request* |

360 | 70/123 | 1500/1000 | 31000 |