Plates thermal cutting and drilling

Automatic gantry style CNC high definition plasma & oxy-fuel cutting system for plates. Kronos HP, SP & PC models are heavy duty gantry style thermal cutting systems engineered for steel fabricators who need to generate diverse plate parts from stock plates.The Ficep Kronos integrates all the cutting, marking and drilling processes into one single operation to reduce material handling cost.

Kronos HP & SP series can be equipped with up to four oxy-fuel cutting torches to cover all manufacturing needs.

One or two high-definition plasma torches for straight and bevel cutting are available. The Kronos can be configured with either the XPR170 or XPR300 torches from Hypertherm

Hypertherm “True Hole” process is available on this model.

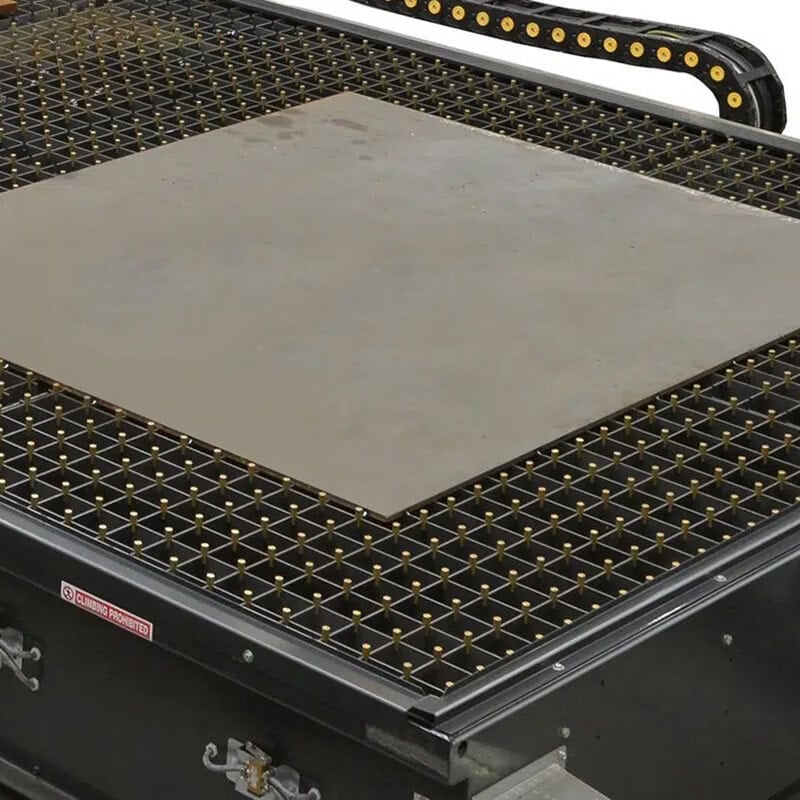

The cutting bench is made of a sturdy grid suitable to guarantee the stable positioning of the plate during the processing. The bench is pre-arranged to receive the fume exhaust and filtering system.

The exhaust system filters the particulate matter generated by the thermal cutting operations. The air is filtered according to the latest health and safety requirements.

Kronos HP & SP series can be combined in tandem with another Kronos or with our Gemini plate cutting and drilling system to optimize the productivity with lower costs.

Kronos HP & SP series have the possibility to be equipped with a drilling unit with a 4 or 6 positions tool changer, to allow for both pre-hole applications.

Kronos can be integrared with an independent 4-axis robotic part unloading system to enhance its productivity and automation

| Kronos | Plate size [max.mm] | Plate thickness with plasma [max.mm] | Plasma straight torches [max.no.] | Plasma bevel torches [max.no.] | Plate thickness with oxy-fuel [max.mm] | Oxy-fuel-fuel torches [max.no.] | Drilling heads [max.no.] | Drilling tools per head [max.no.] | Drilling diameter [max.mm] | Spindle power [kW] | Spindle speed [max.RPM] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KR25SP | 2540 x 6000 | 50 | 1 | 1 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 2500 |

| KR32SP | 3100 x 6000 | 50 | 1 | 1 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 2800 |

| KR36SP | 3600 x 6000 | 50 | 1 | 1 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 3000 |

| KR36SP | 2540 x 6000 | 80 | 2 | 2 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 2500 |

| KR32HP | 3100 x 6000 | 80 | 2 | 2 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 2800 |

| KR32HP | 3600 x 6000 | 80 | 2 | 2 | 150 | 4 | 1 | 6 | 40 | 15 | 6000 | 3000 |

| Kronos | Plate size [max.mm] | Plate thickness with plasma [max.mm] | Plasma straight torches [max.no.] | Machine weight [kg] |

|---|---|---|---|---|

| KR153PC | 1500 x 3000 | 50 | 1 | 4000 |

| KR204PC | 2000 x 4000 | 50 | 1 | 5000 |

| KR206PC | 2000 x 6000 | 50 | 1 | 7500 |

| KR208PC | 2000 x 8000 | 50 | 1 | 10000 |